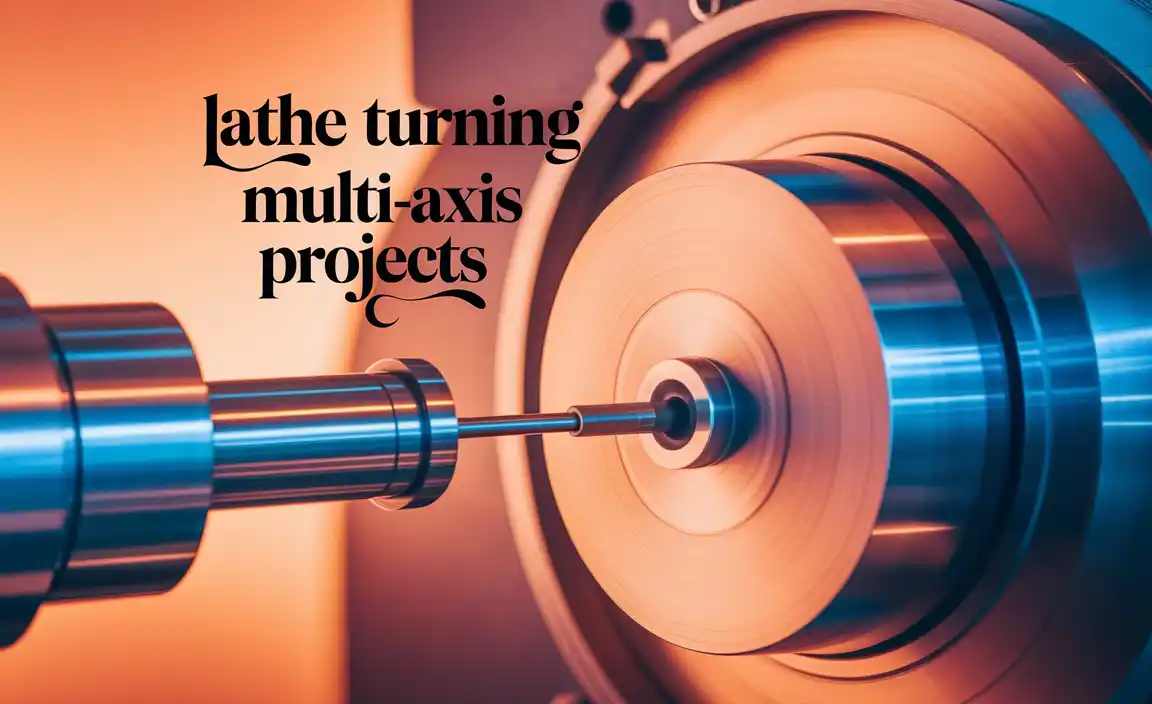

Do you enjoy working with metal? If so, you might love using a lathe. A lathe is a powerful tool that shapes metal into the items we use every day. But have you ever wondered about the power requirements for a metal lathe? Understanding this can help you get the best from your projects.

One exciting feature of many lathes is the quick change tool post. It allows you to switch tools easily while working. Imagine working on a project where you need different tools for different tasks. With a quick change tool post, that task becomes much simpler.

Did you know that the power needed for your lathe affects how well it performs? If you use the wrong power supply, you might not get the results you want. It’s essential to know what your machine needs to run smoothly.

In this article, we will explore lathe power requirements and the benefits of a quick change tool post. Get ready to unlock the full potential of your metalworking skills!

Lathe Power Requirements For Metal Lathe Quick Change Tool Post

Lathe Power Requirements and Quick Change Tool Post

Understanding the power requirements for a metal lathe is essential. A lathe needs enough power to handle various materials efficiently. It can struggle with harder metals if the motor is too weak. Many lathes come with a quick change tool post. This feature allows you to switch tools easily and quickly. Imagine needing to change a tool without wasting time! With this setup, you can work faster and more efficiently. Overall, knowing these basics will help improve your project outcomes.Understanding Lathe Power Requirements

Explanation of horsepower and torque in relation to metal lathes. Importance of matching power requirements with material types.Power is essential for metal lathes. Horsepower shows how much work the machine can do. Torque tells how much force the lathe can use to turn materials. It is important to match the power requirements with different materials to get good results. For example:

- Soft materials need less power.

- Hard materials require more torque.

- Choosing the right power helps avoid machine damage.

What is horsepower and torque?

Horsepower measures how quickly work is done, while torque is the twisting force. Both are vital for lathes to shape metal safely and effectively.

Why is matching power important?

- Using the wrong power can break tools.

- It affects the quality of the finished product.

- Proper power ensures safety and efficiency.

Factors Influencing Power Requirements

Material density and hardness. Depth of cuts and feed rates.Several factors play a big part in how much power you need for your lathe. First, the material’s density and hardness matter. Harder metals need more power to cut through. A soft metal like aluminum feels like butter compared to tough steel. Next, the depth of cuts and feed rates come into play. A deeper cut means more power, and a faster feed rate adds to that. Think of it as trying to slice a cake with a dull knife—it’s much harder!

| Factor | Impact |

|---|---|

| Material Density | Harder materials need more power. |

| Depth of Cuts | Deeper cuts require extra effort. |

| Feed Rates | Faster feeds increase power demands. |

Calculating Lathe Power for Different Applications

Stepbystep guide to calculate needed horsepower for various tasks. Examples of different projects and corresponding power needs.To figure out how much horsepower you need for your lathe, start by measuring the job at hand. Different materials and tasks require different power levels. For example, cutting soft metals like aluminum is less power-hungry, while tough materials like steel need more ooomph. Here’s a simple table to help you out:

| Project | Material | Power Needed (HP) |

|---|---|---|

| Cutting Aluminum | Aluminum | 1-2 HP |

| Turning Steel | Steel | 2-5 HP |

| Working with Cast Iron | Cast Iron | 3-6 HP |

Remember, it’s like cooking. You need just the right amount of heat! If you have more horsepower, you can tackle bigger jobs. Don’t worry; it won’t turn you into a real-life superhero, but it will help you shape metal like a pro!

Benefits of Quick Change Tool Posts

Efficiency improvements and time savings. Enhancements in precision and repeatability.Using a quick change tool post can save you time and boost your efficiency. You can switch tools fast, reducing downtime during projects. This means more work gets done in less time. Quick change tool posts also improve precision. Each tool is easy to set up, leading to consistent results. No need to tweak settings with every change. These benefits lead to better quality work and happier users!

Why is a quick change tool post important?

It is important because it enhances efficiency and increases precision. Users can switch tools quickly, improving productivity and reducing mistakes.

Energy Efficiency in Lathe Operations

Tips for optimizing power usage across different materials. The role of maintenance in power efficiency.Using energy wisely in lathe operations can save you money and keep your machine happy. First, choose the right tool for your material. For instance, harder metals need more power, while softer materials are like butter under a hot knife—easy to cut! Regular maintenance is key too. Think of it as giving your lathe a spa day; clean and oil parts to keep them running smoothly. A well-maintained lathe uses less power, so you can enjoy more time creating and less on the bills!

| Material Type | Power Optimization Tip |

|---|---|

| Aluminum | Use faster speeds for smooth cuts! |

| Steel | Choose sharper tools; they need less power. |

| Brass | Run at medium speed; it’s a delicate dance! |

And remember, keeping things clean means less energy wasted! Your lathe will thank you by keeping running like a champ. Plus, who doesn’t love saving a few bucks?

Safety Considerations for Power and Tool Post Use

Importance of proper equipment setup and maintenance. Safety guidelines to follow while operating metal lathes.Setting up and maintaining your lathe is very important. It keeps you safe and helps it work well. Always check the equipment for wear and tear. Follow safety guidelines, like:

- Wear safety glasses to protect your eyes.

- Keep the workspace clean and free of clutter.

- Don’t wear loose clothes or jewelry.

- Make sure guards are in place on the lathe.

When you respect safety, you make the shop a better place for everyone. Remember, safety is everyone’s job!

Why is proper equipment setup important?

Proper setup helps prevent accidents and improve efficiency. A well-maintained machine performs better and lasts longer.

Conclusion

In summary, understanding lathe power requirements is crucial for optimal performance. A metal lathe with a quick change tool post saves time and boosts productivity. You should choose the right power based on your projects. Explore more about these tools to improve your skills. Happy machining, and remember, practice makes perfect!FAQs

Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Quick Change Tool Posts For Metal Lathes:Sure! When using a lathe, it needs power to spin and shape metal. The more heavy the workpiece, the more power you need. Quick change tool posts help you switch tools fast. This saves time when you’re doing different jobs. Always use the right power for the job to stay safe!

Sure! Please provide the question you’d like me to answer.

What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe?When deciding how much power a metal lathe needs, think about its size and what you want to make. A bigger lathe needs more power to cut through tough metal. You also need to consider how hard the metal is. Softer metals need less power, while harder ones need more. Lastly, consider how fast you want the lathe to spin; faster speeds require more power too.

How Does The Design Of A Quick Change Tool Post Affect The Efficiency And Setup Time In A Metal Lathe Operation?A quick change tool post helps you change tools on a metal lathe quickly. This means you don’t waste time while working. It lets you set up your machine faster, so you can make more pieces in less time. When you can switch tools easily, your work becomes smoother and more efficient. Overall, it makes everything faster and helps you get your job done better!

What Are The Advantages Of Using A Quick Change Tool Post Over A Standard Tool Post In A Lathe?Using a quick change tool post makes changing tools on a lathe much faster. You can switch tools without extra steps, saving time. This means you can finish your work quicker. It also helps keep your tools organized and easier to reach. So, you can work more efficiently and make cool projects faster!

How Can Insufficient Power Supply Impact The Performance And Accuracy Of A Metal Lathe During Heavy Cutting Operations?If a metal lathe doesn’t get enough power, it can slow down. This makes it hard for the machine to cut metal properly. You might end up with uneven shapes or rough surfaces. This can lead to mistakes in your work. So, having enough power is important for doing a good job!

What Are Some Common Power Ratings For Different Sizes Of Metal Lathes, And How Do These Ratings Influence Their Use In Various Machining Applications?Metal lathes come in different sizes, and their power ratings often range from 1 to 10 horsepower (HP). Smaller lathes, like those with 1 or 2 HP, are good for light jobs and small pieces. Bigger lathes, with 5 HP or more, can handle heavy materials and big projects. The power rating tells you how strong the lathe is and helps you choose the right one for your work. Higher power means you can do tougher jobs!