Lathe Power Requirements For Metal Lathe Saddle Operations

Lathe Power Requirements for Metal Lathe Saddle

Understanding the lathe power requirements for a metal lathe saddle is key to effective machining. A lathe needs enough power to handle different materials, cutting speeds, and precision tasks. Too little power can stall the machine, while too much can cause damage. It’s essential to choose a lathe motor that fits the job. Did you know that using the right power can improve the lifespan of your tools? This knowledge can make all the difference in your metalworking projects!What is a Metal Lathe Saddle?

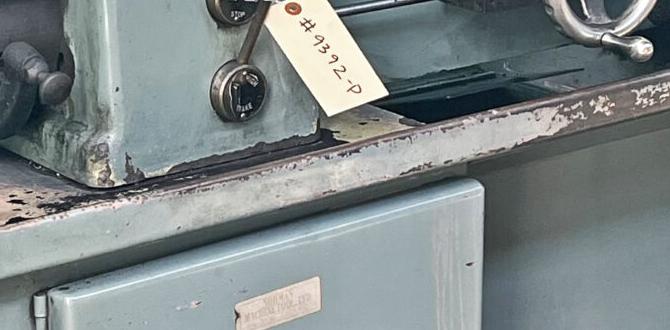

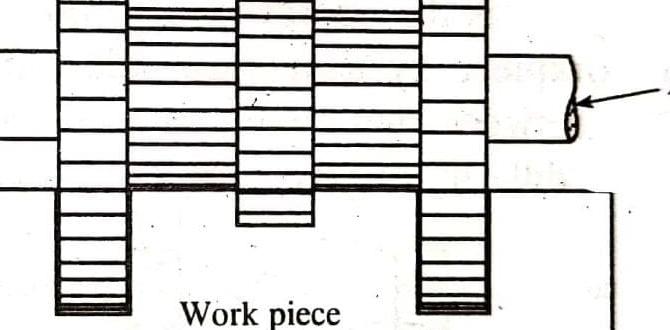

Definition and purpose of a metal lathe saddle. Importance of the saddle in lathe operations.A metal lathe saddle is a key part of a lathe machine. It holds the tool holder and moves along the bed. This allows the tool to shape and cut metal. The saddle’s movement is essential for accuracy in lathe operations. Without it, the metal piece cannot be shaped properly. Each lathe saddle should fit its machine well for the best results. Accuracy is crucial in making precise parts for machines and tools.

What is the purpose of a metal lathe saddle?

The saddle’s purpose is to support the cutting tools and allow smooth movement. It enables precise shaping of metal pieces during machining.

Importance of the Saddle:

- Holds the cutting tool securely.

- Ensures smooth movement for better precision.

- Helps create accurate metal parts quickly.

Factors Influencing Lathe Power Requirements

Material types and their impact on power consumption. Cutting speed and feed rate considerations.Several factors play a role in how much power a lathe uses. First, the type of material you’re working with matters. Harder metals need more juice! Softer materials are like a piece of cake. Then, there’s cutting speed and feed rate. Speeding things up leads to more power consumption, just like your little brother zooming around the house when he’s excited! Balance these elements for a smooth ride on your lathe journey.

| Material Type | Power Consumption |

|---|---|

| Soft Metals | Low |

| Hard Metals | High |

Calculating Power Requirements for Metal Lathe Saddles

Essential formulas for power calculations. Example calculations based on different materials and operations.To compute power needs for metal lathe saddles, use simple formulas. The basic formula is Power (P) = Torque (T) * Angular Speed (ω). Torque is influenced by the material you cut. Here are example calculations:

- For aluminum, use low torque and speed.

- For steel, increase torque and find the right speed.

Adjusting the formulas based on material aids in finding the right power!

What is the formula for calculating power requirements?

The formula is Power (P) = Torque (T) * Angular Speed (ω). This helps in understanding how much power a lathe requires to operate effectively.

Common Mistakes in Estimating Power Requirements

Typical errors in calculation and their consequences. Tips to avoid pitfalls in power estimations.Many people make simple mistakes while figuring out power needs for their lathe. One common error is underestimating the machine’s requirements. If you don’t give your lathe enough power, it can overheat or even break down. On the flip side, overestimating can lead to wasteful energy use. Here are some tips to avoid these pitfalls:

| Common Errors | Consequences | How to Avoid |

|---|---|---|

| Ignoring material type | Inadequate performance | Check material specs |

| Not considering lathe size | Overheating | Match size with power |

Always check your calculations and remember: a lathe without enough juice is like a car without gas—it doesn’t go anywhere!

Choosing the Right Motor for Your Lathe Saddle

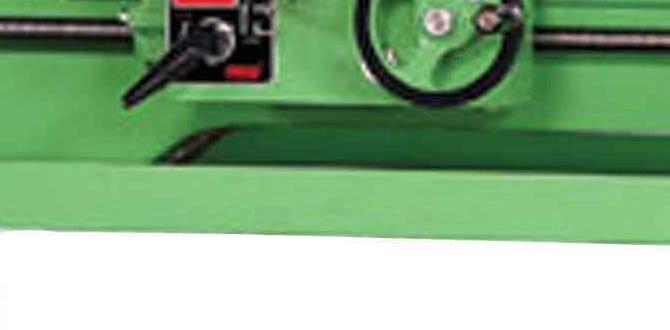

Types of motors used in metal lathes. Factors to consider when selecting a motor.Picking a motor for your lathe saddle is vital. Different motors can change how well your lathe works. You have a few types to think about:

- AC Motors

- DC Motors

- Stepper Motors

When you choose a motor, keep these points in mind:

- Power output

- Speed control

- Size and weight

The right motor helps your lathe run smoothly. This choice makes metal shaping easier and better!

What type of motor is best for a lathe?

For a lathe, AC motors are often preferred for their consistency. DC motors work well for speed control. Stepper motors are great for precision.

Power Efficiency and Its Importance

Benefits of optimizing power usage. Strategies to enhance power efficiency in lathe operations.Using power wisely in lathe operations is like saving your pocket money for candy. It helps keep your machines running longer and cuts costs. Optimizing power use means more efficient work and less waste. To boost this efficiency, try using energy-saving modes on your machines or check for any leaks in the system. Every little change can make a big difference!

| Strategy | Benefit |

|---|---|

| Using energy-saving modes | Reduces power consumption |

| Regular maintenance | Improves machine longevity |

| Training operators | Enhances skill and efficiency |

Remember, every watt counts! So, put on your thinking cap and start saving power—your wallet will thank you!

Maintenance Tips for Power Systems in Lathes

Routine checks to ensure optimal power performance. Common issues and their solutions.Keeping your lathe’s power system in check is like giving it a cup of coffee—you want it energized and running smoothly. Start with routine checks. Ensure all wires are secure. Look for any scary sparks or suspicious noises, which could mean trouble is brewing. If you find issues, don’t panic! A loose connection can often be fixed with a simple twist. Below is a handy table for common problems and quick fixes:

| Common Issue | Possible Solution |

|---|---|

| Power not reaching the lathe | Check the power cord and connections |

| Frequent tripping of circuit | Inspect for overloaded circuits |

| Inconsistent power | Look for loose wires or damaged parts |

Following these tips makes maintenance less of a chore and more of a routine! After all, a happy lathe means smoother projects!

Resources for Further Learning

Recommended books and online courses. Industry standards and guidelines for lathe operations.Learning about lathes can be exciting and helpful. Here are some great resources:

- Books: – *The Machinist’s Handbook* – *Metalworking for Beginners*

- Online Courses: – Coursera: Intro to Metalworking – Udemy: Learn Lathe Basics

- Industry Standards: – OSHA Safety Guidelines for Machining – ANSI B11.6 for Lathe Operations

These resources can help you master the lathe and stay safe while working. Happy learning!

What are some good resources for learning about lathes?

Great resources include books like *The Machinist’s Handbook* and online courses from sites like Coursera. Industry standards from OSHA help ensure safety during operations.

Conclusion

In summary, understanding lathe power requirements is crucial when using a metal lathe saddle. You need to match the lathe’s power to its tasks. This ensures safety and efficiency. To work effectively, check your machine’s specifications carefully. We encourage you to explore more about lathe mechanics for better skills and knowledge. Happy turning!FAQs

What Factors Influence The Power Requirements Of A Metal Lathe Saddle During Machining Operations?Several factors affect how much power a metal lathe saddle needs while working. First, the type of metal being cut matters a lot. Harder metals require more power. Second, the speed of the lathe changes the energy needed. Faster speeds often use more power. Finally, the size and shape of the part you are making can also change power needs. Bigger or more complex parts usually need extra energy.

How Does The Size And Material Of The Workpiece Being Cut Affect The Power Needed For The Lathe Saddle?The size and material of the piece you are cutting matter a lot. Bigger pieces need more power because they are heavier. Also, hard materials, like metal, take more force to cut than soft materials, like wood. So, if you’re cutting something big and tough, your lathe needs more energy to do the job.

What Are The Minimum Power Specifications For A Metal Lathe Saddle To Effectively Handle Heavy-Duty Machining Tasks?To handle heavy-duty tasks, a metal lathe saddle needs enough power. Usually, a motor with at least 2 to 5 horsepower is good. This helps cut tough metal easily. You want to make sure it can keep working without slowing down. More power means better and faster machining!

How Can The Efficiency Of A Metal Lathe Saddle Be Optimized To Reduce Overall Power Consumption During Operation?To make a metal lathe saddle work better and use less power, you can keep it clean and well-lubricated. Regularly check for any worn parts and replace them if needed. You should also adjust the speed and feed levels for the job you’re doing. Lastly, make sure the machine is set up correctly to reduce strain, which helps save energy.

What Role Does The Design And Construction Of The Lathe Saddle Play In Its Power Requirements And Machining Performance?The lathe saddle holds the part we are working on. Its design helps it move smoothly. If it’s made well, the lathe needs less power to work. This means it can cut shapes better and faster. A good saddle helps make sure your projects come out nice!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Influence The Power Requirements Of A Metal Lathe Saddle During Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Several factors affect how much power a metal lathe saddle needs while working. First, the type of metal being cut matters a lot. Harder metals require more power. Second, the speed of the lathe changes the energy needed. Faster speeds often use more power. Finally, the size and shape of the part you are making can also change power needs. Bigger or more complex parts usually need extra energy.”}},{“@type”: “Question”,”name”: “How Does The Size And Material Of The Workpiece Being Cut Affect The Power Needed For The Lathe Saddle? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and material of the piece you are cutting matter a lot. Bigger pieces need more power because they are heavier. Also, hard materials, like metal, take more force to cut than soft materials, like wood. So, if you’re cutting something big and tough, your lathe needs more energy to do the job.”}},{“@type”: “Question”,”name”: “What Are The Minimum Power Specifications For A Metal Lathe Saddle To Effectively Handle Heavy-Duty Machining Tasks? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To handle heavy-duty tasks, a metal lathe saddle needs enough power. Usually, a motor with at least 2 to 5 horsepower is good. This helps cut tough metal easily. You want to make sure it can keep working without slowing down. More power means better and faster machining!”}},{“@type”: “Question”,”name”: “How Can The Efficiency Of A Metal Lathe Saddle Be Optimized To Reduce Overall Power Consumption During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe saddle work better and use less power, you can keep it clean and well-lubricated. Regularly check for any worn parts and replace them if needed. You should also adjust the speed and feed levels for the job you’re doing. Lastly, make sure the machine is set up correctly to reduce strain, which helps save energy.”}},{“@type”: “Question”,”name”: “What Role Does The Design And Construction Of The Lathe Saddle Play In Its Power Requirements And Machining Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe saddle holds the part we are working on. Its design helps it move smoothly. If it’s made well, the lathe needs less power to work. This means it can cut shapes better and faster. A good saddle helps make sure your projects come out nice!”}}]}