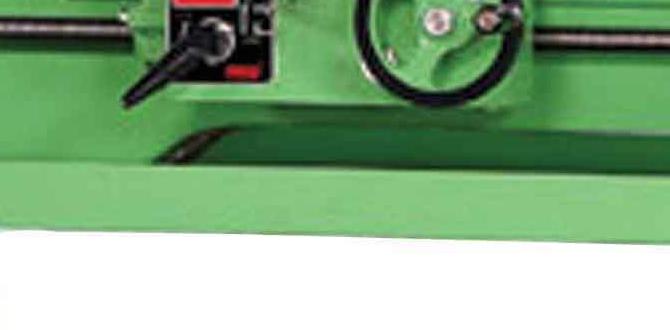

Have you ever wondered how a lathe works? These machines can turn metal into incredible shapes. But there’s a lot more to them than just spinning a piece of metal. Understanding lathe power requirements is key for anyone looking to use one safely.

Imagine starting a project with a metal lathe. You’re excited to create something new, but did you check if your machine has enough power? If it’s not properly powered, it could lead to problems or even accidents. Safety is the number one priority when working with machines.

Did you know that even small mistakes can cause big issues? Many hobbyists overlook the importance of lathe safety. They focus more on getting the job done. However, knowing how to operate a metal lathe safely can make all the difference. It keeps you, your workspace, and your projects safe.

This article will guide you through everything you need to know about lathe power requirements and safety tips. Ready to dive in?

Lathe Power Requirements: Ensuring Metal Lathe Safety

Lathe Power Requirements and Metal Lathe Safety

Using a metal lathe can be fun and rewarding. However, it’s important to understand its power needs. The right power source ensures smooth operation and precision. Safety is crucial when working with lathes. Always wear protective gear and keep your workspace organized. Did you know that most accidents happen due to lack of focus? Stay alert to prevent injuries. By following power requirements and safety tips, you can enjoy a safer and more efficient machining experience.Calculating the Power Requirements of a Metal Lathe

Key formulas and calculations for determining required horsepower. Relationship between torque and spindle speed for efficient machining.To find out how much power a metal lathe needs, you can use some simple formulas. First, remember the magic number: Horsepower = (Torque x RPM) / 5252. This tells you how to mix torque and speed for top results. If you’re wondering about efficient machining, high torque at low speed is often better than the other way around. Here’s a handy table to offer a quick look at some values:

| Spindle Speed (RPM) | Torque (ft-lbs) | Horsepower |

|---|---|---|

| 1000 | 10 | 1.9 |

| 500 | 20 | 1.9 |

| 250 | 40 | 1.9 |

Should your lathe run like a race car or a turtle? It all depends on your project! Keep these formulas in mind to choose the right power for your machining needs. After all, a well-powered lathe can keep you out of sticky situations, like having to hand-crank your metal. Yikes!

Electrical Supply and Motor Specifications

Types of motors used in metal lathes and their power ratings. Understanding singlephase vs. threephase power systems.Choosing the right motor is key for a metal lathe. Most lathes use either single-phase or three-phase motors. Single-phase motors work well for small projects and lighter jobs. They’re like that friend who just shows up now and then. Three-phase motors, however, offer more power and are great for heavy-duty tasks. Think of them as your overachieving buddy who lifts weights every morning!

| Motor Type | Power Rating Range |

|---|---|

| Single-Phase | 1 – 3 HP |

| Three-Phase | 3 – 10 HP |

So, when you’re setting up your lathe, remember: power matters. The right motor keeps your projects spinning smoothly and safely. Power up and get ready for some metal magic!

Importance of Proper Power Settings

Consequences of underestimating power requirements. Impact of power settings on machining accuracy and finish quality.Choosing the right power settings for your lathe is not a joke. If you underestimate the power needed, you might end up with uneven cuts or a finish that looks like a three-year-old’s art project. This can lead to wasted materials and time, which is no fun. Proper power settings help achieve sharper accuracy and a better finish, letting you show off your work instead of hiding it under the rug. Remember, using the right power means happier projects!

| Power Setting | Machining Accuracy | Finish Quality |

|---|---|---|

| Low | Inaccurate | Poor |

| Optimal | Sharp | Excellent |

| Too High | Variable | Rough |

In short, respect your lathe and its power needs, and it will respect your creations in return!

Common Hazards in Metal Lathe Operation

Identification of risks: entanglement, chip flying, and noise hazards. Strategies for hazard prevention and risk mitigation.Working with a metal lathe can be fun, but it comes with some risks. Entanglement is a common hazard. Loose clothing or long hair can catch in the machine. Ouch! Then there are flying chips that can surprise you like popcorn at a movie. Wear safety glasses to protect your eyes. Lastly, noise hazards can be a problem. Always use ear protection to keep your hearing safe. A little care goes a long way in keeping you safe while you create!

| Hazard | Prevention Strategy |

|---|---|

| Entanglement | Secure loose clothing and tie back hair. |

| Flying chips | Wear safety glasses and use shields. |

| Noise | Use ear protection at all times. |

Emergency Procedures and First Aid for Lathe Incidents

Essential steps to take in case of accidents or power failures. Basic first aid measures every metal lathe operator should know.Accidents can happen, even with careful use of a lathe. Here are some essential steps to follow during an emergency:

- Turn off the lathe immediately.

- Assess the situation carefully.

- Call for help if someone is hurt.

Every metal lathe operator should know basic first aid. Here are some quick tips:

- For cuts, apply pressure to stop bleeding.

- Use a clean cloth for burns.

- Keep the injured person calm until help arrives.

Stay prepared and stay safe!

What should you do first in a lathe emergency?

Turn off the machine immediately and then assess the situation to ensure everyone is safe.

What is a quick first aid tip for cuts?

Apply pressure with a clean cloth to help stop the bleeding.

Resources for Further Learning about Lathe Safety and Power Requirements

Recommended books, courses, and websites for indepth knowledge. Importance of continuous education and training in metalworking safety.Learning about lathe safety and power needs is essential. Many resources can help you dive deeper into this subject. Books and online courses provide valuable insights. Check out trusted websites too. Continuous education ensures you stay safe while working. Here are some useful resources:

- Books: “Metalworking Safety” and “Lathe Basics.”

- Online Courses: Look for courses on metalworking platforms.

- Websites: Visit sites like OSHA and the Metalworking Association.

Staying informed is the key to being safe around lathes. Always keep learning!

What are some recommended resources for lathe safety?

You can find great materials on lathe safety, like books, websites, and online courses. These resources can help you understand safety practices and power requirements better.

Conclusion

In conclusion, understanding lathe power requirements is crucial for safe metalworking. Always check your machine’s specifications to ensure you choose the right power supply. Follow safety guidelines to protect yourself while you work. Remember: wear protective gear and stay focused. Explore more resources on lathe safety to build your skills. Together, we can create safe and successful projects!FAQs

What Factors Determine The Power Requirements For Operating A Metal Lathe Effectively?To run a metal lathe, you need enough power to turn and shape metal. The size and weight of the metal piece matter because heavier pieces need more power. The speed at which you work also affects the power needed; faster speeds usually require more power. Lastly, the type of metal influences the requirements; harder metals need more power to cut.

How Can Operators Ensure Safety While Working With A Lathe, Especially In High-Speed Applications?To stay safe while using a lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Make sure to follow all safety rules for the machine. Never reach near the spinning part while it’s running. Lastly, if you feel unsure, ask for help.

What Specific Safety Equipment Should Be Worn When Operating A Metal Lathe?When you use a metal lathe, you should wear safety goggles to protect your eyes. It’s also important to wear snug fitting gloves to keep your hands safe. Make sure to put on a dust mask if there’s dust in the air. Finally, wear sturdy shoes to protect your feet from falling tools.

How Does The Size And Type Of Material Being Machined Impact The Power Needs Of A Metal Lathe?The size and type of material you are cutting with a metal lathe affects how much power it needs. Bigger pieces of metal need more power to move and cut. Hard materials, like steel, also require more power than softer ones, like aluminum. If you use a small, soft piece, the lathe needs less power to work. So, choosing the right size and material helps the lathe work better.

What Are Some Common Safety Hazards Associated With Using A Lathe, And How Can They Be Mitigated?Using a lathe can be risky. You can get hurt by sharp tools, spinning parts, or chips that fly off. To stay safe, always wear safety goggles and keep your hair tied back. Make sure to follow all the safety rules and never rush when you work. Lastly, keep your workspace clean so you don’t trip or slip.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Determine The Power Requirements For Operating A Metal Lathe Effectively? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To run a metal lathe, you need enough power to turn and shape metal. The size and weight of the metal piece matter because heavier pieces need more power. The speed at which you work also affects the power needed; faster speeds usually require more power. Lastly, the type of metal influences the requirements; harder metals need more power to cut.”}},{“@type”: “Question”,”name”: “How Can Operators Ensure Safety While Working With A Lathe, Especially In High-Speed Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To stay safe while using a lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so nothing gets caught. Make sure to follow all safety rules for the machine. Never reach near the spinning part while it’s running. Lastly, if you feel unsure, ask for help.”}},{“@type”: “Question”,”name”: “What Specific Safety Equipment Should Be Worn When Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a metal lathe, you should wear safety goggles to protect your eyes. It’s also important to wear snug fitting gloves to keep your hands safe. Make sure to put on a dust mask if there’s dust in the air. Finally, wear sturdy shoes to protect your feet from falling tools.”}},{“@type”: “Question”,”name”: “How Does The Size And Type Of Material Being Machined Impact The Power Needs Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size and type of material you are cutting with a metal lathe affects how much power it needs. Bigger pieces of metal need more power to move and cut. Hard materials, like steel, also require more power than softer ones, like aluminum. If you use a small, soft piece, the lathe needs less power to work. So, choosing the right size and material helps the lathe work better.”}},{“@type”: “Question”,”name”: “What Are Some Common Safety Hazards Associated With Using A Lathe, And How Can They Be Mitigated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a lathe can be risky. You can get hurt by sharp tools, spinning parts, or chips that fly off. To stay safe, always wear safety goggles and keep your hair tied back. Make sure to follow all the safety rules and never rush when you work. Lastly, keep your workspace clean so you don’t trip or slip.”}}]}