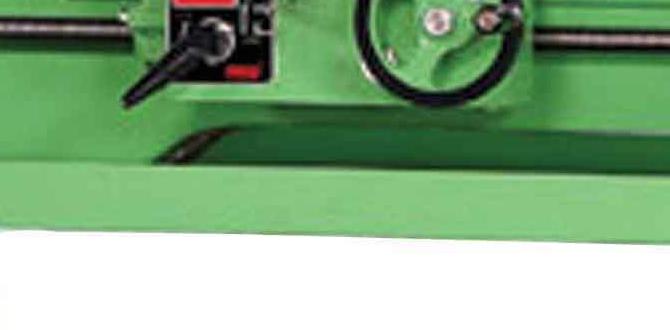

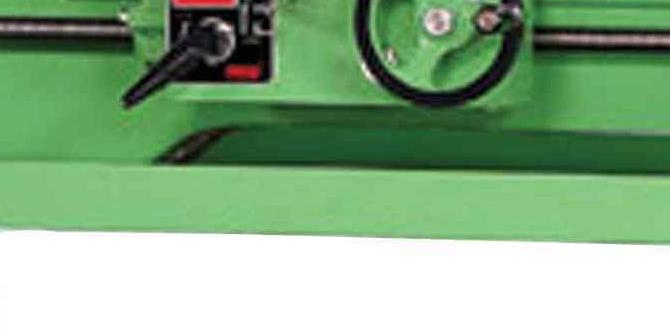

Have you ever wondered how those shiny metal parts are made? Many come from machines called lathes. But what happens when you need to cut threads on metal with a lathe? It requires not just skill but also the right lathe power requirements.

Imagine trying to cut a thread with a toy tool. It wouldn’t work well, right? The same goes for metal lathes. They need enough power to cut smoothly and accurately. If the power isn’t right, the work can go wrong. But how do you know what power you need?

Surprisingly, many people overlook this key point! Understanding lathe power needs is crucial for thread cutting. Whether you are a hobbyist or a pro, knowing these details can help you achieve better results. So, let’s dive deeper into lathe power requirements and explore the world of metal lathe thread cutting together.

Lathe Power Requirements For Metal Lathe Thread Cutting In The World Of Machining, Understanding Lathe Power Requirements Is Crucial, Especially When It Comes To Tasks Like Metal Lathe Thread Cutting. Operating A Metal Lathe Effectively Involves Not Only The Skill Of The Machinist But Also A Keen Awareness Of The Machine’S Capabilities, Particularly Its Power Requirements. Properly Assessing These Requirements Can Significantly Impact The Quality Of The Threads Produced, As Well As The Efficiency And Safety Of The Machining Process. Understanding Lathe Power Requirements Lathe Power Requirements Refer To The Amount Of Power Needed To Operate The Lathe Effectively. This Can Be Influenced By Several Factors, Including The Type Of Material Being Machined, The Size And Specifications Of The Lathe, And The Specific Operations Being Performed, Such As Thread Cutting. Factors Influencing Power Requirements 1. **Material Type**: Different Metals Have Varying Levels Of Hardness And Toughness. For Instance, Cutting Tools Used On Softer Materials Like Aluminum Will Demand Less Power Compared To Harder Materials Such As Steel Or Titanium. 2. **Thread Cutting Specifications**: The Dimensions Of The Threads, Including Pitch And Depth, Also Play A Vital Role In Determining The Power Needed. More Intricate And Deeper Cuts Will Inevitably Consume More Power. 3. **Lathe Specifications**: The Horsepower Rating Of The Lathe Motor Provides A Baseline For Power Requirements. A Lathe With A Higher Horsepower Rating Can Effectively Handle More Demanding Tasks, Providing Greater Versatility For Complex Thread Cutting Operations. Estimating The Power Requirements To Estimate The Power Required For A Specific Lathe Operation, Machinists Often Refer To Formulas That Factor In The Material’S Specific Cutting Energy, The Depth Of Cut, Feed Rate, And The Cutting Speed. Such Calculations Ensure That The Lathe Operates Within Its Capacity, Reducing The Risk Of Failure And Enhancing The Quality Of The Finished Product. Conclusion Understanding Lathe Power Requirements Is Essential For Anyone Involved In Metal Lathe Thread Cutting. By Considering The Material Being Machined, The Intricacies Of The Thread Specifications, And The Capabilities Of The Lathe, Machinists Can Choose The Right Tools And Settings For Optimal Performance. Proper Assessment Not Only Leads To Better Thread Quality But Also Ensures A More Efficient And Safer Machining Process.

Lathe Power Requirements for Metal Lathe Thread Cutting

Understanding lathe power requirements is key for successful metal lathe thread cutting. A lathe needs sufficient power to cut threads smoothly. If the lathe is underpowered, it may struggle, leading to poor thread quality. Did you know that a powerful motor allows for faster and easier threading? Choosing the right motor size and type ensures great results. Properly sizing your lathe’s power helps you avoid common mistakes and enhances your metalworking experience.Factors Influencing Power Requirements

Material type and hardness considerations. Diameter and length of the thread being cut.Several factors affect how much power is needed for a lathe. First, the material type impacts the cutting process. Softer materials need less power, while harder ones need more strength. Second, the diameter and length of the thread also matter. Thicker and longer threads require higher power to cut smoothly.

What types of materials need more power when cutting threads?

Hard materials like steel demand higher power for effective cutting. Softer materials such as aluminum use less.

Key Points:

- Material Type: Harder materials = more power needed

- Diameter: Thicker threads = increased power

- Length: Longer threads = higher power requirements

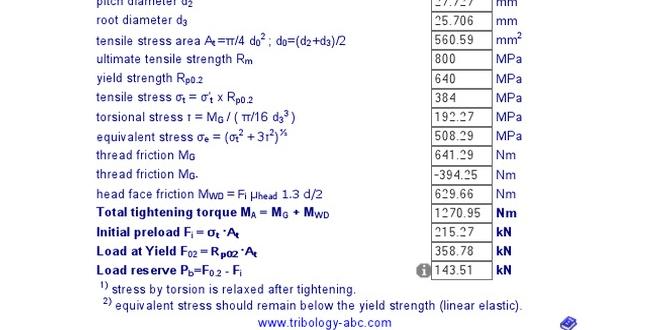

Calculating Power Needs for Thread Cutting

Formula for calculating horsepower or kilowatts needed. Example calculations for common metal types.To calculate the power needed for thread cutting, you can use this formula: Horsepower = (Torque x RPM) / 5252 or its kilowatt version. Let’s look at an example. For cutting aluminum, you may need 0.5 to 1 horsepower. For steel, you might require 1 to 2 horsepower. Always consider the material when planning your project. Matching power to material ensures smooth and safe cutting.

What is the formula for calculating horsepower?

The formula for calculating horsepower is: Horsepower = (Torque x RPM) / 5252. This helps you find the right power depending on what you’re cutting.

- Aluminum: 0.5 – 1 HP

- Steel: 1 – 2 HP

- Cast Iron: 1.5 – 3 HP

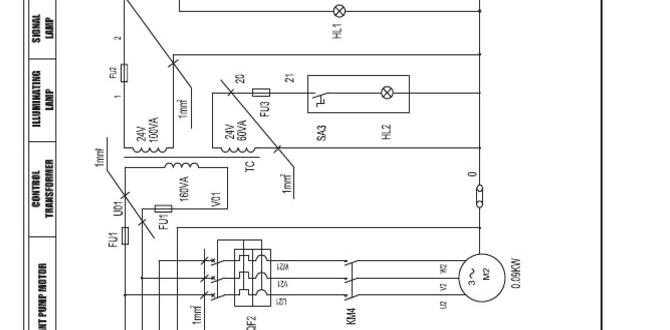

Recommended Motor Sizes for Various Lathes

Standard motor sizes for hobby vs. industrial lathes. Comparison of singlephase vs. threephase motors.Choosing the right motor size is important for lathes. Hobby lathes usually need smaller motors, like 1-2 HP. Industrial lathes require bigger motors, often from 3-10 HP. The type of motor also matters:

- Single-phase motors are simple and cheaper.

- Three-phase motors are strong and run smoother.

Knowing what your lathe needs will make your projects easier. Always check the motor size before starting!

What motor size should I choose for a lathe?

For most hobby lathes, a motor size of 1 to 2 HP works well. Industrial models often use motors from 3 to 10 HP.

Energy Efficiency in Lathe Operations

Tips for optimizing power consumption. Benefits of selecting energyefficient motors.Using less energy while working on a lathe is important. Here are some tips to save power:

- Choose the right size lathe for your job.

- Keep the lathe clean and well-maintained.

- Use variable-speed motors when possible.

- Optimize cutting speeds based on material.

Choosing energy-efficient motors can greatly reduce energy costs. They use less electricity and last longer. This means more savings and less waste. Happy machining!

What are the benefits of energy-efficient motors?

They save energy, lower costs, and have a longer lifespan.

Upgrading Power Supply for Larger Projects

When and why to consider an upgrade. Steps for upgrading your lathe’s power supply system.Upgrading your lathe’s power supply might feel like changing a light bulb, but it’s a bit more complex. If you’re tackling bigger projects or need more power for thread cutting, it’s time for an upgrade. Look for signs like your lathe slowing down or shutting off unexpectedly. To upgrade, first, check your current setup and power needs. Then, choose a compatible power supply. Don’t forget safety first—always unplug before tinkering!

| Step | Action |

|---|---|

| 1 | Assess current power needs |

| 2 | Select a suitable power supply |

| 3 | Install with safety gear |

In the wise words of a power supply guru, “More power means more fun!” So, don’t shy away from gathering some extra juice for those larger projects!

Resources for Further Learning

Recommended books and online courses for mastering lathe operations. Community forums and workshops for handson experience.Books and online courses can be great tools for learning about lathe operations. Look for titles that focus on metal lathe thread cutting. Websites like YouTube and specialized platforms offer step-by-step courses as well. Also, consider joining community forums and local workshops. These places let you ask questions and practice hands-on skills. Learning from others helps you master the trade.

What are some good resources for lathe learning?

- Books: “The Lathe Book” by Ernie Conover

- Online Courses: Udemy and Skillshare have great options

- Community Forums: CNCZone and Reddit’s Machinists community

- Workshops: Local maker spaces often offer classes

Conclusion

In summary, understanding lathe power requirements is key for successful metal lathe thread cutting. You need enough horsepower to handle different materials. This knowledge helps you choose the right lathe for your projects. Keep practicing and exploring more about lathes to improve your skills. Check out additional resources or guides to learn even more about this exciting craft!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements For Metal Lathe Thread Cutting:When you use a lathe to cut threads on metal, the machine needs power to work. This power helps the lathe turn and shape the metal. Different metals need different amounts of power to cut correctly. If the lathe doesn’t have enough power, it may not cut well. Always check the lathe’s power needs before starting your project!

Sure! Please let me know what question you would like me to answer.

What Factors Influence The Power Requirements Of A Metal Lathe During Thread Cutting Operations?The power needs of a metal lathe while cutting threads depend on a few things. First, the thickness of the metal you are working on matters. Thicker metal needs more power. Second, the speed at which you turn the lathe can change the power needed. Finally, the type of thread you are cutting can also affect power use. All these factors work together to decide how much power the lathe needs.

How Do Different Thread Profiles (E.G., Standard, Metric, Or Custom Threads) Affect The Power Needed For Cutting On A Lathe?Different thread profiles, like standard or metric, change how hard it is to cut. When we cut threads, we need power to push the tool through the metal. If the threads are thicker or deeper, it takes more power. Custom threads can be tricky too, so they might need extra energy to cut. In short, the shape and size of the threads affect how much power we need.

What Is The Recommended Horsepower For A Lathe Used Specifically For Thread Cutting Applications?For thread cutting on a lathe, you usually want about 1 to 3 horsepower. This power helps make clean and strong threads. If you do heavy cutting or work with tough materials, you might need a bit more power. Always choose a lathe with enough horsepower for your specific projects.

How Does The Material Being Machined (Such As Steel, Aluminum, Or Brass) Impact The Power Requirements For Thread Cutting On A Lathe?The type of material we use affects how much power we need for cutting threads. Hard materials like steel need more power because they are tough to cut. Softer materials, like aluminum, need less power and are easier to shape. Brass is in between; it’s not too hard and not too soft. So, the harder the material, the more power we will use.

What Techniques Can Be Implemented To Optimize Power Usage While Maintaining Precision During Thread Cutting On A Metal Lathe?To save power while cutting threads on a metal lathe, you can start by using sharp tools. Sharp tools cut through metal easier, so you need less energy. You should also adjust the speed of the lathe to match the material you’re using. Slower speeds can save power and still make precise cuts. Lastly, keep the machine clean and well-oiled to help it run smoothly.