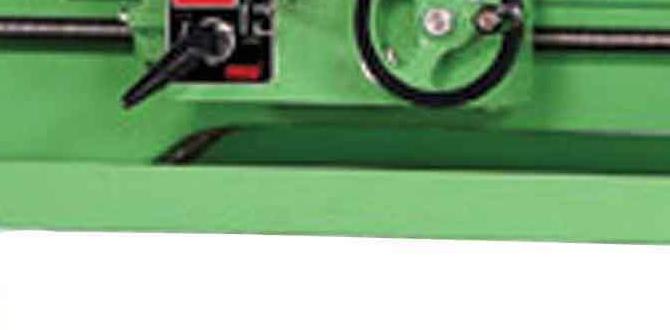

Have you ever faced a problem while using your metal lathe? Perhaps it suddenly stopped working, or maybe it wasn’t cutting smoothly. These issues can be frustrating. One key factor in maintaining a metal lathe is understanding its power requirements.

Did you know that the right power supply is essential for optimal performance? If your lathe doesn’t get enough power, it won’t run effectively. This can lead to poor results, like uneven cuts or even damage to your machine.

Imagine working on a vital project, and your lathe begins to act up. You might wonder: where did I go wrong? Troubleshooting your lathe often starts with checking these power requirements. Knowing how much power your lathe needs can save time and stress.

In this article, we’ll explore common issues and how to solve them. You’ll discover tips for checking power needs and keeping your metal lathe in top shape. Being prepared is the key to a successful woodworking or metalworking project!

Lathe Power Requirements: Metal Lathe Troubleshooting Tips

Lathe Power Requirements and Troubleshooting

Understanding lathe power requirements is crucial for any metalworking project. Did you know that an underpowered lathe can cause frustration and poor results? Having the right voltage and amperage ensures smooth operation. If you face issues like unusual noises or vibrations, troubleshooting can help identify the problem. Regular maintenance and checking connections can keep your lathe running well. Knowing these key points empowers you to make the most of your metal lathe.Common Power-Related Issues in Metal Lathes

Identification of symptoms indicating power problems. Analysis of how power fluctuations affect lathe operation.Power issues in metal lathes can show up in different ways. Common signs include strange noises, uneven cuts, or errors in speed settings. These problems usually mean the machine isn’t getting the right power. Power fluctuations can make the lathe slow, stall, or even overheat. Regular checks can help identify these issues early:

- Inconsistent speed

- Vibration or noise changes

- Frequent tripping of circuit breakers

How to identify power issues effectively?

Look for changes like unusual sounds or weak performance. Keeping an eye on these signs can help fix problems fast!

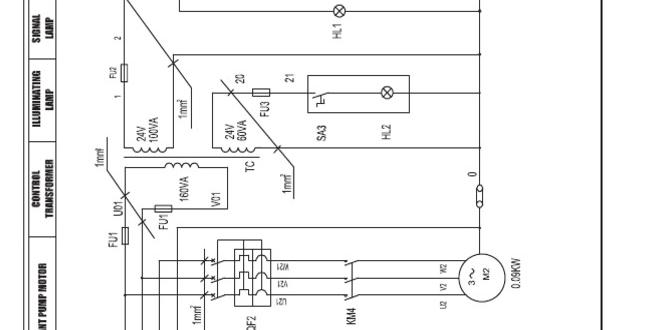

Troubleshooting Lathe Power Requirements

Stepbystep guide to diagnosing power issues. Tools needed for effective troubleshooting.Diagnosing power issues with a lathe can feel like finding a needle in a haystack. First, check the power source. Is it plugged in or taking a nap? Next, ensure all switches are in the right position—sometimes they just need a little chat to wake up! You’ll need some handy tools: a multimeter, wire strippers, and maybe a flashlight for those tricky spots. Here’s a quick tool checklist:

| Tool | Purpose |

|---|---|

| Multimeter | Measure voltage and continuity |

| Wire Strippers | Fix damaged wires |

| Flashlight | Light up dark corners |

With these tools ready, you can tackle any power hiccup with confidence. Don’t worry—every lathe has its quirky days!

Adjusting Power Settings for Optimal Performance

Explanation of adjusting speed and torque settings. Best practices for maintaining consistent power supply.For the best results with your lathe, adjusting speed and torque is key. Speed changes how fast the tool moves, while torque affects turning power. Finding the right balance is important. Here are some tips to keep a steady power supply:

- Check the power source regularly.

- Keep wires and connections clean.

- Use the right settings for the material.

This helps you avoid problems and work smoothly. Remember, a well-maintained lathe can make your projects easier and more enjoyable!

How do I know the right speed for my lathe?

Start with a lower speed and increase it gradually. Always consult the material guidelines for the best results. Every type of material has its ideal speed.

Understanding Electrical Requirements for Different Lathe Models

Comparison of singlephase vs threephase power options. Recommendations for different lathe sizes and types.Choosing the right power for your lathe is vital. There are two main types: single-phase and three-phase. Single-phase power is common in homes, while three-phase power is stronger and best for larger machines. Here’s a quick guide:

- Small Lathes: Single-phase (1HP or less).

- Medium Lathes: Single-phase (1-2HP) or three-phase (2-3HP).

- Large Lathes: Three-phase (3HP or more) for better performance.

Understand your needs to select the best power option! A three-phase lathe can handle heavy tasks without stress, while a single-phase lathe is easier to set up.

What type of power does a lathe need?

It depends on the lathe size and usage. Generally, small lathes use single-phase power, while larger lathes need three-phase for efficiency.

Safety Considerations When Dealing with Power Issues

Key safety tips to follow during troubleshooting. Importance of disconnecting power before maintenance.Before diving into troubleshooting a metal lathe, safety should be your top priority. Always disconnect the power before starting any maintenance. Imagine trying to fix your favorite toy while it’s still plugged in. Ouch, right? Always wear safety glasses and gloves. They might not make you look like a superhero, but they sure keep you safe! Here are some key tips:

| Safety Tip | Description |

|---|---|

| Disconnect Power | Always unplug the machine before you start working. |

| Wear Protection | Use safety glasses and gloves to protect yourself. |

| Stay Alert | Focus on the task to avoid accidents. |

Following these tips keeps you safe and sound. Remember, a few laughs can lighten the mood, but safety is no joke! Be smart and enjoy your time with the lathe.

Preventative Measures for Power-Related Issues

Routine maintenance practices to ensure optimal power delivery. Tips for choosing the right power source for your lathe.Keeping your lathe in tip-top shape can prevent many power problems. Regular check-ups are key! Clean the machine and check the wires often. A little love goes a long way. For power sources, choose wisely—match the voltage to your lathe’s needs. If your lathe loves 220 volts, don’t feed it 110 volts! That’s like serving a salad to someone who only eats pizza. Here’s a quick table for power choices:

| Voltage | Recommended Use |

|---|---|

| 110 Volts | For smaller projects |

| 220 Volts | For heavy-duty machines |

Remember, a small amount of prevention can save big headaches later!

Resources for Further Assistance

Recommended troubleshooting guides and manuals. Contact information for expert service providers in lathe maintenance.Having trouble with your lathe? Don’t worry, help is close at hand! You can explore some handy troubleshooting guides and manuals online. These resources can guide you step-by-step, turning confusion into confidence. And if things go really off track, reach out to pros who know lathes like the back of their hand. They can save the day—or at least, your metal! Here’s a nifty chart with some great options:

| Resource Type | Description | Contact Information |

|---|---|---|

| Troubleshooting Guide | Easy-to-follow, with pictures! | www.lathehelp.com/guides |

| Expert Service Providers | Friendly techs ready to assist. | 1-800-Lathe-Fix |

With these resources, you’ll be on your way to lathe mastery in no time. Now that’s something to smile about!

Conclusion

In conclusion, understanding lathe power requirements is crucial for effective metal lathe troubleshooting. You should check if the power supply matches your lathe’s needs. Regular maintenance helps prevent issues and keeps machinery running smoothly. If you face problems, refer to troubleshooting guides for practical solutions. Keep learning about lathe operation for better results in your projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Troubleshooting:Sure! A lathe is a machine that helps us shape metal or wood. To use a lathe, it needs a power source, like electricity. If your lathe stops working, check if it’s plugged in or if the switch is turned on. Sometimes the blades might need sharpening, so you can fix that too! If you keep having problems, ask an adult for help.

Sure! Please ask your question, and I’ll provide a short answer.

What Factors Determine The Power Requirements For Operating A Metal Lathe Effectively?To use a metal lathe well, we need to consider a few important things. First, the size and type of the metal we are cutting matter. Bigger and tougher metals need more power. Second, how fast we want to cut also affects power needs. Finally, the tools we use can change the power requirement, too. We want to make sure we have enough power to do the job right!

How Can I Diagnose And Resolve Issues Related To Insufficient Power Supply To My Metal Lathe?To check the power supply to your metal lathe, first, make sure it’s plugged in and the outlet works. You can do this by testing another device in the same outlet. Next, look for any loose wires or damage on the power cord. If it still doesn’t work, check the breaker box to see if a fuse has blown or a breaker has tripped. If problems continue, ask a grown-up to help you contact a repair person.

What Are Common Signs That A Metal Lathe May Be Overloaded Or Not Receiving Adequate Power?You might notice a metal lathe struggling to work smoothly. The machine may make strange noises or stop suddenly. If it feels hot to the touch, that’s a warning sign. Also, the cuts on the metal could look rough or uneven. These signs mean the lathe may be overloaded or not getting enough power.

What Safety Precautions Should Be Taken When Troubleshooting Power Issues On A Metal Lathe?When fixing power problems on a metal lathe, we need to be very careful. First, always turn off the machine before touching it. Next, unplug it to make sure it can’t start accidentally. Wear safety glasses to protect your eyes from flying pieces. Finally, keep your hands and clothes away from moving parts.

How Do Different Types Of Materials Being Machined Affect The Power Consumption Of A Metal Lathe?Different materials, like soft metals or hard steels, use power differently on a metal lathe. Soft metals, like aluminum, require less power to cut. Harder materials, like steel, need more power because they are tougher. So, the harder the material, the more energy the lathe uses. This affects how much electricity you need while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Troubleshooting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal or wood. To use a lathe, it needs a power source, like electricity. If your lathe stops working, check if it’s plugged in or if the switch is turned on. Sometimes the blades might need sharpening, so you can fix that too! If you keep having problems, ask an adult for help.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll provide a short answer.”}},{“@type”: “Question”,”name”: “What Factors Determine The Power Requirements For Operating A Metal Lathe Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use a metal lathe well, we need to consider a few important things. First, the size and type of the metal we are cutting matter. Bigger and tougher metals need more power. Second, how fast we want to cut also affects power needs. Finally, the tools we use can change the power requirement, too. We want to make sure we have enough power to do the job right!”}},{“@type”: “Question”,”name”: “How Can I Diagnose And Resolve Issues Related To Insufficient Power Supply To My Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the power supply to your metal lathe, first, make sure it’s plugged in and the outlet works. You can do this by testing another device in the same outlet. Next, look for any loose wires or damage on the power cord. If it still doesn’t work, check the breaker box to see if a fuse has blown or a breaker has tripped. If problems continue, ask a grown-up to help you contact a repair person.”}},{“@type”: “Question”,”name”: “What Are Common Signs That A Metal Lathe May Be Overloaded Or Not Receiving Adequate Power?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a metal lathe struggling to work smoothly. The machine may make strange noises or stop suddenly. If it feels hot to the touch, that’s a warning sign. Also, the cuts on the metal could look rough or uneven. These signs mean the lathe may be overloaded or not getting enough power.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Troubleshooting Power Issues On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When fixing power problems on a metal lathe, we need to be very careful. First, always turn off the machine before touching it. Next, unplug it to make sure it can’t start accidentally. Wear safety glasses to protect your eyes from flying pieces. Finally, keep your hands and clothes away from moving parts.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Materials Being Machined Affect The Power Consumption Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials, like soft metals or hard steels, use power differently on a metal lathe. Soft metals, like aluminum, require less power to cut. Harder materials, like steel, need more power because they are tougher. So, the harder the material, the more energy the lathe uses. This affects how much electricity you need while working.”}}]}