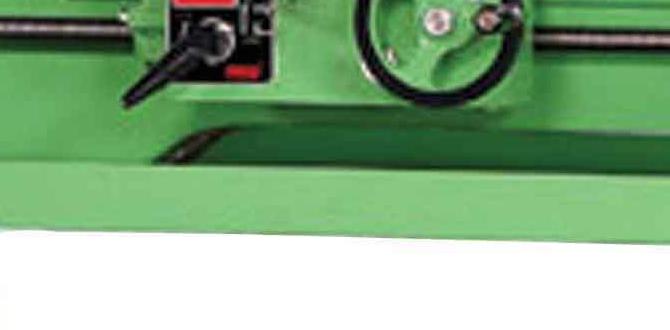

Have you ever looked at a metal lathe and wondered how it works? These machines are powerful tools used to shape and cut metal. But did you know that understanding lathe power requirements is crucial for using them safely and effectively?

Imagine deciding to build something cool with metal. You get your hands on a lathe, but wait! Do you know how much power you need? This is where a good wiring diagram comes in handy. It helps show how to connect everything correctly.

Power requirements can change based on the size and type of lathe. For instance, small lathes may need less power than larger ones. If you plug in the wrong machine, it can lead to trouble. Knowing the right power needs keeps your projects running smoothly.

Many hobbyists and makers face this question. Your project’s success often depends on the right setup. This article will guide you through the power requirements for metal lathes and how to read a wiring diagram. Let’s dive in and learn how to turn your ideas into reality!

Lathe Power Requirements: Understanding Metal Lathe Wiring Diagram

Lathe Power Requirements and Wiring Insights

Understanding lathe power requirements is essential for safe and efficient operation. The right power helps prevent tool damage. Did you know that wiring your metal lathe correctly reduces the risk of electrical issues? A proper wiring diagram shows you how to connect power safely. You’ll learn about voltage needs, amperage, and the type of circuits needed. This knowledge ensures smooth running and longevity for your lathe. Are you ready to master your metalworking skills?Common Types of Motors Used in Metal Lathes

AC vs. DC motors and their applications. Stepper and servo motors: benefits and considerations.When it comes to powering metal lathes, the choice of motor is vital. AC motors are common and great for simple tasks, while DC motors shine in precise speed control. They’re like the superheroes of motors: each has its own special power! Then we have stepper motors. They move in tiny steps, making them perfect for detailed work. On the flipside, servo motors offer super accuracy and speed but come at a higher cost. Talk about choosing your battles!

| Motor Type | Strengths | Considerations |

|---|---|---|

| AC Motor | Reliable & simple | Limited speed control |

| DC Motor | Excellent speed control | Can be pricey |

| Stepper Motor | Precise movement | Slower speed |

| Servo Motor | Super accuracy | Higher cost |

Choosing the right motor can make your lathe work like a dream or a complete nightmare. So, pick wisely and keep your projects spinning smoothly!

Power Sources for Metal Lathes

Singlephase vs. threephase power connections. Transforming voltage for optimal performance.Choosing the right power source for your metal lathe is like picking the best ice cream flavor—everyone has their favorite! For small shops, a single-phase connection might work. It’s simple and easy to use. However, if you’re serious about big projects, consider a three-phase setup. It offers better efficiency and reliability.

Transforming voltage is just as important. You want your lathe to perform like a pro, not like a sloth. Proper voltage ensures it runs smoothly without a huff or puff! And remember, having a wiring diagram handy can turn a messy job into a breeze. Here’s a quick look at the differences:

| Power Type | Advantages |

|---|---|

| Single-Phase | Easy installation, good for small machines |

| Three-Phase | Better performance, ideal for heavy-duty work |

Understanding Lathe Wiring Diagrams

Key components in a wiring diagram. How to read and interpret a lathe wiring diagram.Wiring diagrams for lathes show how everything connects. They help us understand the power flow. Key components in these diagrams include the motor, switches, and power source. Each part has a clear role. To read a diagram, follow these steps:

- Identify symbols for components. They represent different parts.

- Trace the lines. They show how electricity moves.

- Look for notes. They explain special features or connections.

Reading a wiring diagram is like solving a puzzle. With practice, it becomes easier and more fun!

What are the main parts of a lathe wiring diagram?

The main parts include:

1. Motor – This powers the lathe.

2. Switches – These control the lathe’s operation.

3. Power source – This provides electricity to the lathe.

Creating Your Own Wiring Diagram

Stepbystep guide to designing a wiring diagram. Tools and materials needed for wiring a metal lathe.Designing a wiring diagram for your metal lathe is easier than you think. First, gather your tools: wires, tape, connectors, and a good attitude—no one likes grumpy wiring! Start by sketching the main parts: motor, control panel, and power source. Make sure to connect everything logically. Use color coding to avoid mix-ups. Here’s a handy table to help you keep track:

| Tool or Material | Purpose |

|---|---|

| Wire Cutters | To cut wires to length |

| Electrical Tape | To secure connections |

| Connectors | For joining wires |

| Screwdriver | To tighten screws |

Follow these steps, and your lathe will be humming in no time—like a cat purring after a good snack! Remember to check connections before powering up, so you don’t create a new dance move called “The Shock Shuffle!”

Common Wiring Errors and Troubleshooting Tips

Identifying common wiring mistakes in metal lathes. Effective troubleshooting techniques for electrical issues.Wiring errors can cause big problems in metal lathes. Common mistakes include wrong connections and using the wrong wire size. These can lead to equipment failures or even safety issues. To fix these errors, follow effective troubleshooting steps:

- Check all connections carefully.

- Verify the wire size matches the requirements.

- Look for any frayed or damaged wires.

- Test the power source to ensure it works.

By paying attention to these details, you can keep your lathe running smoothly and safely.

What are some typical wiring mistakes in metal lathes?

Common errors include miswired connections and incorrect wire gauges. These can cause malfunctions and may even lead to injuries.

How can I troubleshoot electrical issues with my lathe?

Start by checking connections, ensure wire sizes are correct, and test the power source. This approach helps identify and fix problems efficiently.

Safety Measures When Wiring and Operating Metal Lathes

Personal protective equipment (PPE) requirements. Recommended safety practices for electrical work with lathes.When working with metal lathes, safety is key. Always wear personal protective equipment (PPE) to protect yourself. This includes:

- Safety goggles to shield your eyes.

- Ear protection to reduce noise.

- Gloves to keep hands safe from cuts.

- Steel-toed boots for foot protection.

Follow these safety rules while wiring and operating lathes:

- Turn off the power before starting work.

- Check for loose wires regularly.

- Use insulated tools to avoid shocks.

- Keep the work area tidy.

Being careful can help you avoid accidents and injuries while using machines. Safety first!

What is PPE?

PPE stands for personal protective equipment. It keeps workers safe while they operate machines or deal with hazardous materials.

Why is safety important?

Safety is crucial to prevent accidents and protect health in the workplace. It helps everyone go home safe at the end of the day.

Resources for Further Learning

Recommended books and manuals on lathe wiring and power requirements. Online forums and communities for metalworking enthusiasts.If you want to dive deeper into the world of lathe wiring and power needs, there are many great resources to explore. Consider checking out books like *”Metalworking: A Beginners Guide”* or *”Lathe Wiring Made Simple.”* These can be your trusty sidekicks on this journey. Online communities, like the “Metal Lathe Lovers” forum, are also fantastic for asking questions and sharing jokes about your latest workshop mishaps. Remember, every expert was once a beginner with a funny story!

| Resource Type | Name |

|---|---|

| Book | Metalworking: A Beginners Guide |

| Book | Lathe Wiring Made Simple |

| Online Forum | Metal Lathe Lovers |

Conclusion

In conclusion, understanding lathe power requirements is essential for safe and effective use. A clear wiring diagram helps you set up your metal lathe correctly. Make sure you follow the guidelines to prevent accidents. Now that you know the basics, take the time to explore more about lathe operation. Happy machining!FAQs

Certainly! Here Are Five Related Questions Regarding Lathe Power Requirements And Wiring Diagrams For Metal Lathes:To answer your request, I need the specific questions about lathe power requirements and wiring diagrams. Please provide them, and I’ll be happy to help!

Sure! Just ask your question, and I’ll give you a short and simple answer.

What Are The Typical Power Requirements For A Metal Lathe Based On Its Size And Intended Applications?Metal lathes need different amounts of power, depending on their size and what you want to make. Small lathes might need around 1 to 2 horsepower. Bigger lathes could need 5 to 10 horsepower or more. The power helps the lathe turn fast and cut metal easily. So, the more heavy-duty the work, the more power you’ll need!

How Do You Determine The Appropriate Wire Gauge For Wiring A Metal Lathe To Ensure Safety And Efficiency?To choose the right wire gauge for a metal lathe, check the tools’ power needs. You can find this information in the lathe’s manual, like how many amps of electricity it uses. A thicker wire can carry more power safely. If you’re not sure, ask an adult for help to make the right choice. Always prioritize safety to avoid any accidents!

What Components Are Essential In A Wiring Diagram For A Metal Lathe, And How Do They Function Together?A wiring diagram for a metal lathe shows how parts connect. You need a power supply to give energy. Switches control the power, turning it on and off. The motor makes the lathe spin, and wires connect everything. Each part works together to help the lathe shape metal.

How Can Voltage Variations Affect The Performance Of A Metal Lathe, And What Measures Can Be Taken To Mitigate Potential Issues?Voltage changes can make a metal lathe work poorly. If the voltage is too low, the machine might run slowly. If it’s too high, it could break or even catch fire. To prevent this, we can use a voltage regulator. This device keeps the voltage steady and helps the lathe run smoothly.

What Safety Precautions Should Be Considered When Wiring A Metal Lathe To Comply With Electrical Codes And Standards?When wiring a metal lathe, you should always turn off the power first. Use a circuit breaker to protect against overloads. Make sure all wires are secured and insulated, so they don’t touch anything else. Label all wires clearly to avoid mistakes. Finally, check that everything meets safety rules for electricity.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions Regarding Lathe Power Requirements And Wiring Diagrams For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To answer your request, I need the specific questions about lathe power requirements and wiring diagrams. Please provide them, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a short and simple answer.”}},{“@type”: “Question”,”name”: “What Are The Typical Power Requirements For A Metal Lathe Based On Its Size And Intended Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes need different amounts of power, depending on their size and what you want to make. Small lathes might need around 1 to 2 horsepower. Bigger lathes could need 5 to 10 horsepower or more. The power helps the lathe turn fast and cut metal easily. So, the more heavy-duty the work, the more power you’ll need!”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Wire Gauge For Wiring A Metal Lathe To Ensure Safety And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right wire gauge for a metal lathe, check the tools’ power needs. You can find this information in the lathe’s manual, like how many amps of electricity it uses. A thicker wire can carry more power safely. If you’re not sure, ask an adult for help to make the right choice. Always prioritize safety to avoid any accidents!”}},{“@type”: “Question”,”name”: “What Components Are Essential In A Wiring Diagram For A Metal Lathe, And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A wiring diagram for a metal lathe shows how parts connect. You need a power supply to give energy. Switches control the power, turning it on and off. The motor makes the lathe spin, and wires connect everything. Each part works together to help the lathe shape metal.”}},{“@type”: “Question”,”name”: “How Can Voltage Variations Affect The Performance Of A Metal Lathe, And What Measures Can Be Taken To Mitigate Potential Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Voltage changes can make a metal lathe work poorly. If the voltage is too low, the machine might run slowly. If it’s too high, it could break or even catch fire. To prevent this, we can use a voltage regulator. This device keeps the voltage steady and helps the lathe run smoothly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Considered When Wiring A Metal Lathe To Comply With Electrical Codes And Standards?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, you should always turn off the power first. Use a circuit breaker to protect against overloads. Make sure all wires are secured and insulated, so they don’t touch anything else. Label all wires clearly to avoid mistakes. Finally, check that everything meets safety rules for electricity.”}}]}