Have you ever wondered how metalworkers create such precise parts? The secret often lies in using the best metal lathe. These powerful tools shape metal with incredible accuracy. But did you know that precision leveling is a key step in making the most of your lathe?

Imagine you have a brand-new metal lathe. You can’t wait to start your project. But if it’s not level, your work might end up uneven or even unusable. That’s frustrating, right? Leveling your lathe ensures you get the best results. Whether you’re a beginner or an expert, this process is important.

In this article, we will explore lathe precision leveling. We will also highlight the top choices for the best metal lathe. With the right tools and knowledge, you can become a master of metalworking.

Lathe Precision Leveling: Best Metal Lathe Techniques To Use

Lathe Precision Leveling: Best Metal Lathe Insights

What makes a metal lathe the best? Precision leveling is crucial for accuracy. A well-leveled lathe helps produce smooth, even cuts. Did you know improper leveling can lead to errors and wasted material? Proper leveling tools, like precision levels and shims, can enhance performance. Consider your workspace as you choose. A stable surface impacts your lathe’s effectiveness. With these tips, you’ll gain better control and improve your projects significantly. Turn your ideas into reality with the right lathe!Understanding Lathe Precision Leveling

Definition of lathe precision leveling and its importance in machining.. Common challenges faced due to improper leveling..Lathe precision leveling means making sure your lathe is perfectly flat and stable. This helps the machine work smoothly while cutting metal. If it’s not level, you might end up with wobbly parts. Yikes! Think of it like a teeter-totter—if one side is higher, it won’t work right. Common problems with improper leveling include uneven cuts and extra wear on tools. Trust me, nobody wants a crooked screw!

| Common Challenges | Effects |

|---|---|

| Uneven Cuts | Parts may not fit together. |

| Tool Wear | Tools break or wear out faster. |

| Inaccurate Measurements | More mistakes in your project. |

Top Features of the Best Metal Lathes for Precision Leveling

Discussion of features that enhance precision, such as DRO (Digital Readout) systems.. The role of stability and material quality in achieving accurate results..Finding the right metal lathe can feel like a treasure hunt. Look for features that boost precision, like Digital Readout (DRO) systems. These nifty gadgets help you measure accurately without squinting. Stability is key, too! A solid base and high-quality materials keep your machine steady—like a cat on a fence. This stability ensures your results are accurate and repeatable.

| Feature | Benefit |

|---|---|

| DRO Systems | Clear measurements for precise cuts |

| Stable Base | Reduces vibrations for accuracy |

| High-Quality Materials | Durability and precise results |

Step-by-Step Guide to Leveling Your Lathe

Tools and materials required for effective leveling.. Detailed procedures for checking and adjusting lathe levels..Gather the right tools first! You’ll need a level, some shims, and wrenches. Sound complicated? Not really! Just think of it as a lathe trust exercise. Here’s a quick guide to get you started:

| Tool | Purpose |

|---|---|

| Level | Check if your lathe is straight |

| Shims | Adjust height as needed |

| Wrenches | Tighten or loosen bolts |

Now, to check the levels, place your level on the bed of the lathe. Adjust until it’s perfectly flat. If it looks like a roller coaster, you need to shim it up! Remember, a well-leveled lathe is a happy lathe. After all, nobody likes working on a tilted surface!

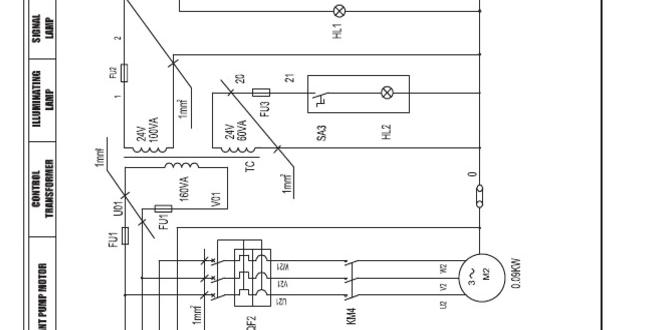

Maintenance Tips for Optimal Lathe Performance

Best practices for routine maintenance to sustain precision.. Importance of lubrication and cleanliness in repairing wear over time..To keep your lathe running smoothly, follow these simple maintenance tips. Daily cleaning helps remove dust and metal shavings. Regular checks for loose parts can prevent bigger problems. Also, remember lubrication is key to avoiding wear. Here are some quick tips:

- Clean the lathe after each use.

- Oil moving parts regularly.

- Inspect belts and gears for wear.

With good care, your lathe will stay precise and last longer. It’s like giving your tools a health check-up!

Why is lubrication important for lathes?

Lubrication reduces friction and keeps parts from wearing out quickly. This helps your lathe work better over time.

Reviews of the Best Metal Lathes on the Market

Comparative analysis of toprated metal lathes focusing on precision leveling.. User feedback and expert insights on performance and value..Finding the right metal lathe is crucial for precision work. Users praise lathes that offer easy precision leveling. Expert reviews often highlight performance and value. Here’s what you need to know:

- Top lathes excel in accuracy.

- Most users report high satisfaction.

- Value for money stands out in reviews.

Picking a high-quality metal lathe makes a big difference in your projects. Look for one with positive feedback and proven reliability.

What should I consider for precision leveling?

Consider ease of adjustment and overall stability for better precision leveling in your metal lathe.

Real-World Applications of Precision Leveling in Metal Lathing

Various industries and projects that benefit from precise lathe operations.. Case studies illustrating the impact of proper leveling on final products..Precision leveling in metal lathing helps many industries. It’s vital for making parts like car engines and airplane wings. When machines are properly leveled, they create better products. For example:

- Automotive: Engines run smoother and last longer.

- Aerospace: Parts fit perfectly, ensuring safety in flight.

- Construction: Tools are accurate, leading to solid structures.

In one case, a company fixed its lathe leveling. This cut waste by 30% and improved quality. Investing in precise operations is smart for any project.

Why is precise leveling important in metal lathing?

Precise leveling ensures high-quality products and reduces mistakes. This leads to less material waste and saves money.

Conclusion

In conclusion, achieving precision leveling on the best metal lathe is essential for quality work. You should always use a reliable level and check your setup carefully. This ensures your projects turn out great every time. For more tips on metal lathes, keep exploring and learning. With practice, you can master precision in your metalworking adventures!FAQs

What Are The Essential Steps For Properly Leveling A Metal Lathe To Ensure Precision In Machining?To level a metal lathe, you first need a level tool. Place it on the lathe’s bed. Adjust the feet until the bubble is centered in the level. Check from different angles to make sure it’s flat. Finally, tighten everything once it’s perfectly level. This helps your machine work better and makes accurate parts.

How Does The Accuracy Of A Lathe’S Leveling Affect The Quality Of Finished Workpieces?If a lathe isn’t level, it can wobble. This means the cutting tool might not stay in the right place. When this happens, the workpiece can turn unevenly. You end up with rough edges and mistakes. So, keeping the lathe level helps make smooth and nice-looking pieces!

What Tools Or Instruments Are Recommended For Checking And Adjusting The Precision Leveling Of A Metal Lathe?To check and adjust the leveling of a metal lathe, you can use a spirit level. This tool helps you see if the lathe is straight. You might also need a set of feeler gauges. These gauges measure tiny spaces and help ensure everything fits correctly. Lastly, a dial indicator is handy for precise measurements.

Are There Specific Features Or Designs In A Lathe That Contribute To Better Leveling And Overall Precision?Yes, some parts of a lathe help it work better. A strong base keeps the lathe steady. Good measuring tools help us check if everything is straight. Also, smooth parts make it easier for the lathe to turn without bumps. All these features help us make precise pieces.

What Common Mistakes Should Be Avoided When Leveling A Metal Lathe To Achieve The Best Precision?When leveling a metal lathe, avoid a few common mistakes. First, don’t skip checking the floor underneath. It should be strong and flat. Second, make sure you use a good level tool to get the right angle. Lastly, don’t forget to tighten all the bolts after you adjust it. This helps keep everything steady while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps For Properly Leveling A Metal Lathe To Ensure Precision In Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you first need a level tool. Place it on the lathe’s bed. Adjust the feet until the bubble is centered in the level. Check from different angles to make sure it’s flat. Finally, tighten everything once it’s perfectly level. This helps your machine work better and makes accurate parts.”}},{“@type”: “Question”,”name”: “How Does The Accuracy Of A Lathe’S Leveling Affect The Quality Of Finished Workpieces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe isn’t level, it can wobble. This means the cutting tool might not stay in the right place. When this happens, the workpiece can turn unevenly. You end up with rough edges and mistakes. So, keeping the lathe level helps make smooth and nice-looking pieces!”}},{“@type”: “Question”,”name”: “What Tools Or Instruments Are Recommended For Checking And Adjusting The Precision Leveling Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the leveling of a metal lathe, you can use a spirit level. This tool helps you see if the lathe is straight. You might also need a set of feeler gauges. These gauges measure tiny spaces and help ensure everything fits correctly. Lastly, a dial indicator is handy for precise measurements.”}},{“@type”: “Question”,”name”: “Are There Specific Features Or Designs In A Lathe That Contribute To Better Leveling And Overall Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some parts of a lathe help it work better. A strong base keeps the lathe steady. Good measuring tools help us check if everything is straight. Also, smooth parts make it easier for the lathe to turn without bumps. All these features help us make precise pieces.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Leveling A Metal Lathe To Achieve The Best Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When leveling a metal lathe, avoid a few common mistakes. First, don’t skip checking the floor underneath. It should be strong and flat. Second, make sure you use a good level tool to get the right angle. Lastly, don’t forget to tighten all the bolts after you adjust it. This helps keep everything steady while you work.”}}]}