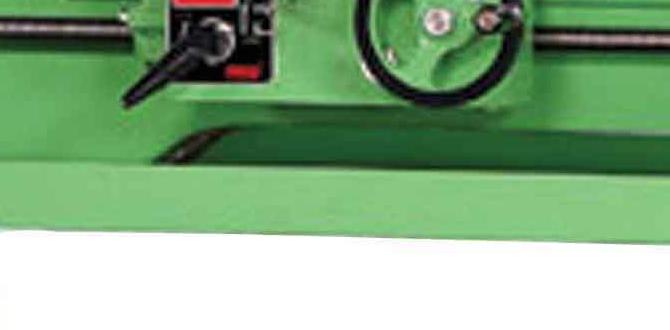

Have you ever wondered how metal parts are made with such incredible precision? It all comes down to the tools used, especially a metal lathe. These machines can shape metal into the exact forms needed for everything from bicycles to airplanes.

But did you know that the secret to perfect metalworking lies in lathe precision leveling? Proper leveling of your lathe ensures that you create parts that fit together perfectly. A small mistake in leveling can lead to big errors in your projects.

Imagine trying to build a model airplane, but the wings don’t fit properly because the lathe was off by just a tiny bit! That’s why it’s essential to have the right metal lathe accessories. These accessories help you achieve that precise leveling you need.

In this article, we will explore different accessories that can improve your lathe’s performance. We’ll also share tips for ensuring your lathe is always perfectly leveled. Get ready to enhance your metalworking skills and create amazing projects!

Lathe Precision Leveling: Essential Metal Lathe Accessories

Lathe Precision Leveling: A Guide to Metal Lathe Accessories

Leveling your lathe is crucial for accuracy and quality of work. Precision leveling ensures your metal lathe operates smoothly, avoiding potential errors. Accessories like leveling pads and adjusting feet are essential for achieving this stability. Have you ever wondered why your metal projects don’t match your expectations? A well-leveled lathe makes all the difference. Proper leveling can improve your craftsmanship and lead to impressive results. With the right tools and setup, anyone can master their lathe and create amazing pieces.Understanding Lathe Precision Leveling

Importance of precision leveling in lathe operations. Common issues caused by improper leveling.Leveling a lathe is like making sure your cake is straight before frosting it. If it’s off, things get messy! Proper leveling is important because it ensures smooth cuts and accurate measurements. Without it, you might face issues like uneven surfaces or even damaging your tools. Imagine trying to ride a bike with flat tires! Here are some common problems due to improper leveling:

| Issue | Result |

|---|---|

| Wobbly Cuts | Inaccurate dimensions |

| Excessive Vibration | Tool wear and tear |

| Uneven Workpieces | Frustration and waste |

Therefore, keep that lathe leveled, and you’ll be cutting like a pro in no time! Remember, a happy lathe means a happy maker!

Key Metal Lathe Accessories for Enhanced Precision

List of essential accessories for increasing lathe accuracy. Description of how each accessory contributes to precision.Using the right accessories can make your lathe work shine! Here’s a short list of essential tools that boost precision:

| Accessory | Benefit |

|---|---|

| Tailstock | Stabilizes workpieces for smoother cuts. |

| Dial Indicator | Measures tiny shifts to keep everything on track. |

| Live Center | Reduces friction and increases rotation accuracy. |

| Chuck | Holds materials tightly, ensuring steady operation. |

These accessories are like superheroes for your metal lathe! Each one helps make your work more accurate and fun. Remember, a happy lathe makes for happy projects!

Common Challenges in Lathe Precision Leveling

Identification of frequent leveling problems and their causes. Solutions and preventive measures for common challenges.Lathe precision leveling is tricky. Workers often face several problems. Common issues include uneven surfaces and machine vibrations. These problems can lead to errors in your work and even damage. Here are some causes and solutions:

- **Uneven floor**: Check the ground. Use shims to balance the lathe.

- **Vibrations**: Tighten loose parts. This helps keep the lathe steady.

- **Temperature changes**: Keep the lathe in a stable environment. This avoids warping.

- **Poor setup**: Always follow instructions. A good start prevents issues.

By recognizing these challenges and using these solutions, you can improve your lathe’s performance. Proper maintenance is key to success!

What are common leveling problems with lathes?

Common problems include uneven surfaces, machine vibrations, and poor setups. These can lead to errors and affect your projects.

Maintaining Lathe Precision Over Time

Best practices for regular maintenance to ensure continued precision. The role of environmental factors in lathe maintenance.Keeping your lathe precise requires regular care. Simple tasks help maintain accuracy. Consider these best practices:

- Clean parts regularly to prevent dirt buildup.

- Check and adjust the leveling frequently.

- Lubricate moving parts to keep them smooth.

- Inspect for loose bolts or parts that may shift.

The environment also affects your lathe’s performance. Maintain a stable room temperature and humidity to avoid warping or rust. Sunlight and dust can harm it, too. Close windows or use covers to protect your lathe.

How often should I maintain my lathe?

It’s best to check your lathe weekly for dirt, and monthly for deeper care like lubrication.

What are signs I need to adjust my lathe?

- Poor cutting quality.

- Strange noises during use.

- Visible wear on parts.

Advanced Leveling Techniques for Professionals

Techniques for achieving high precision in specialized applications. Tips from industry experts on enhancing lathe setup.To achieve high precision with lathe tools, professionals use advanced leveling techniques. One method is using a precision level to ensure the lathe is completely flat. Another is adjusting the tailstock alignment. Here are some tips from industry experts:

- Check surface flatness often.

- Use special leveling supports for uneven floors.

- Regularly calibrate your lathe tools for accuracy.

These methods help reduce errors in machining and improve the overall quality of your work.

What are the best techniques for lathe precision leveling?

The best techniques include ensuring the lathe is level, checking the alignment, and using the right accessories. Regular maintenance helps keep your lathe working well.

Conclusion

In conclusion, using precision leveling for metal lathes ensures accuracy and better results. Accessories like leveling legs and tools can improve your setup. By investing in the right gear, you enhance your projects. Always check your lathe’s level before starting work. Explore more about lathe accessories to boost your skills and create amazing projects. Happy turning!FAQs

What Are The Key Benefits Of Using Precision Leveling Tools For A Metal Lathe Setup?Using precision leveling tools helps you get your metal lathe perfectly flat. This makes your work more accurate and precise. When the lathe is level, it runs smoother and makes better cuts. You also get a longer life for the machine and fewer mistakes in your projects. Overall, it makes working with metal easier and more fun!

How Do You Properly Level A Metal Lathe To Ensure Optimal Performance And Accuracy?To level a metal lathe, you start by using a level tool. Place the level across the lathe bed. Adjust the feet of the lathe until the bubble is centered in the level. Check again in different spots to make sure it’s even. This helps you work accurately and keep your projects looking good!

What Are The Essential Accessories Required For Maintaining The Precision Of A Lathe Machine?To keep a lathe machine working well, you need some important tools. First, a good measuring tool helps you check sizes accurately. You also need a chuck key to hold and adjust the pieces safely. Lubricants, like oil, keep the machine running smoothly. Lastly, a clean cloth helps you wipe off dust and dirt.

How Can Improper Leveling Of A Lathe Affect The Machining Process And The Quality Of Finished Products?If a lathe isn’t leveled right, it can cause parts to wobble. This wobbling makes it hard to cut materials evenly. As a result, the finished product can be rough or misshaped. We want our tools to be accurate, so leveling is really important. If you level the lathe properly, your parts will turn out smoother and nicer.

What Advanced Leveling Techniques Or Tools Can Improve The Precision Of A Metal Lathe Beyond Basic Leveling Methods?To make a metal lathe more precise, we can use special tools like a precision level. This tool helps you see tiny differences in how flat the lathe is. You can also use adjustable pads to balance the machine better. A laser level sends out a beam that helps you check if everything is straight. These advanced tools help us create more accurate parts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Using Precision Leveling Tools For A Metal Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using precision leveling tools helps you get your metal lathe perfectly flat. This makes your work more accurate and precise. When the lathe is level, it runs smoother and makes better cuts. You also get a longer life for the machine and fewer mistakes in your projects. Overall, it makes working with metal easier and more fun!”}},{“@type”: “Question”,”name”: “How Do You Properly Level A Metal Lathe To Ensure Optimal Performance And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you start by using a level tool. Place the level across the lathe bed. Adjust the feet of the lathe until the bubble is centered in the level. Check again in different spots to make sure it’s even. This helps you work accurately and keep your projects looking good!”}},{“@type”: “Question”,”name”: “What Are The Essential Accessories Required For Maintaining The Precision Of A Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe machine working well, you need some important tools. First, a good measuring tool helps you check sizes accurately. You also need a chuck key to hold and adjust the pieces safely. Lubricants, like oil, keep the machine running smoothly. Lastly, a clean cloth helps you wipe off dust and dirt.”}},{“@type”: “Question”,”name”: “How Can Improper Leveling Of A Lathe Affect The Machining Process And The Quality Of Finished Products? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe isn’t leveled right, it can cause parts to wobble. This wobbling makes it hard to cut materials evenly. As a result, the finished product can be rough or misshaped. We want our tools to be accurate, so leveling is really important. If you level the lathe properly, your parts will turn out smoother and nicer.”}},{“@type”: “Question”,”name”: “What Advanced Leveling Techniques Or Tools Can Improve The Precision Of A Metal Lathe Beyond Basic Leveling Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe more precise, we can use special tools like a precision level. This tool helps you see tiny differences in how flat the lathe is. You can also use adjustable pads to balance the machine better. A laser level sends out a beam that helps you check if everything is straight. These advanced tools help us create more accurate parts!”}}]}