Have you ever wondered how precision is achieved in metalworking? Imagine a machine that creates shapes from metal with amazing accuracy. This is where lathe precision leveling comes in. It’s all about making sure every piece of metal is shaped just right.

With modern technology, lathe automation is changing the game. These machines can do complex tasks quickly and without human help. This makes them perfect for busy shops that need high-quality work.

Did you know that even a small error in leveling can lead to big problems? A slightly off machine can ruin a project! This shows just how important it is to get lathe precision leveling right.

So, what’s the secret to perfect metal lathe automation? It’s a mix of smart engineering and careful setup. As we explore this topic, you’ll discover how these machines work and why they matter in today’s world.

Lathe Precision Leveling: Revolutionizing Metal Lathe Automation

Lathe Precision Leveling and Automation

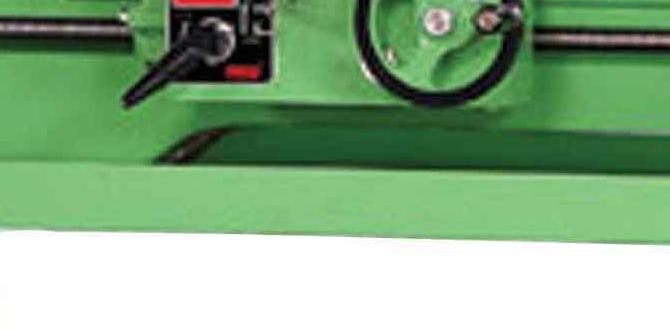

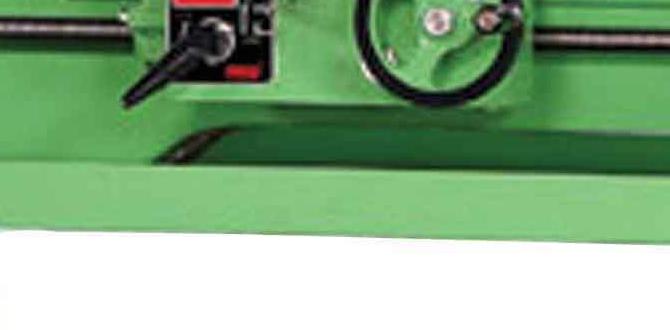

Getting the right precision with metal lathes is vital for quality work. Imagine trying to build a model, but it keeps wobbling because the base isn’t level. That’s how crucial lathe precision leveling is! Automation in lathes makes the process smoother and faster. It reduces manual mistakes and helps in achieving consistent results. With the right setup, you can turn metal into exact shapes effortlessly. Isn’t it amazing how technology can enhance craftsmanship?Understanding Lathe Precision Leveling

Definition of precision leveling in metal lathes. Importance of precision leveling for machining accuracy.Precision leveling in metal lathes is all about getting things straight! It means making sure your lathe is perfectly horizontal. This is crucial for machining accuracy. If your lathe is tilted, your projects can go haywire. You wouldn’t want your masterpiece to look like a wobbly pancake, right? Proper leveling ensures smooth cuts and neat finishes, saving time and materials. Remember, happy lathe, happy craftsman!

| Key Points |

|---|

| Definition: Setting up the lathe flat and level. |

| Importance: Ensures precision and reduces errors. |

Factors Affecting Lathe Precision Leveling

Components of a lathe that influence leveling. Environmental factors (e.g., temperature, flooring).Many parts of a lathe affect how well it levels. Each piece must work together smoothly. If something is damaged, it can cause problems. Other factors also play a role. For example, temperature changes can expand metal, changing how parts fit. The flooring beneath the lathe matters too. A sturdy, level floor helps keep the lathe steady. Consider these key points:

- Lathe bed: It needs to be straight and strong.

- Leveling feet: These help balance the machine.

- Temperature: Extreme heat or cold can affect metal.

- Flooring: Solid foundations ensure stability.

What affects lathe leveling?

Several factors impact lathe leveling, including machine components and the environment. Each part needs to be in good condition.

Step-by-Step Guide to Leveling a Metal Lathe

Preparatory steps before leveling. Detailed techniques for achieving precision leveling.Before leveling a metal lathe, you need to prepare. Start by clearing the area around the lathe. Ensure it is free of dust and debris. Check the floor for cracks or uneven spots. Use a level tool to assess the lathe’s current position.

To achieve precision leveling, follow these detailed steps:

- Use shim plates for small adjustments.

- Adjust the feet of the lathe until it is perfectly level.

- Double-check with the level tool to confirm accuracy.

- Tighten all screws and bolts securely.

Regular leveling helps maintain lathe accuracy, supporting better automation and efficiency.

What is the best way to level a metal lathe?

The best way to level a metal lathe is to use a level tool and adjust the feet accordingly. Regular checks can keep your lathe operating smoothly. Consider using shims for precise adjustments.

Common Mistakes in Lathe Leveling and How to Avoid Them

Frequent errors made during the leveling process. Tips for ensuring a successful leveling procedure.Leveling a lathe is important for precise work. Common mistakes can cause big problems. Here are some frequent errors:

- Not checking the floor beneath the lathe.

- Ignoring the machine’s level while adjusting.

- Forgetting to use a reliable level tool.

To avoid these mistakes, try these tips:

- Always check the surface before leveling.

- Use a calibrated level tool for best results.

- Regularly maintain your lathe.

By following these steps, you can achieve better results and extend the life of your lathe.

What are common mistakes in lathe leveling?

Common mistakes include uneven surfaces, wrong tools, and skipping checks during adjustments.

Maintaining Your Lathe’s Precision After Leveling

Maintenance practices for sustained accuracy. How to periodically check and adjust leveling.Keeping your lathe precise is key to making great parts. Regular care helps maintain accuracy. Check your lathe every month or so. Look for wear and tear, like loose screws or uneven surfaces. Don’t skip adjustments; a small change can make a big difference! To make it easier, here’s a quick table:

| Action | Frequency |

|---|---|

| Check Leveling | Monthly |

| Tighten Screws | Monthly |

| Inspect for Wear | Quarterly |

Remember, lathe maintenance is like brushing your teeth. Skip it, and you’ll end up with a dull tool and some serious cavities in your work!

Case Studies: Successful Lathe Precision Leveling Implementations

Examples from various industries demonstrating effective leveling. Lessons learned from realworld applications.In many industries, effective lathe precision leveling changes everything. For example, a car manufacturing plant improved its output by 20% after leveling its lathes. A watchmaker also increased accuracy by focusing on their lathe setup. Here are some lessons learned:

- Proper leveling reduces machine wear and tear.

- It helps ensure high-quality products every time.

- Regular checks for level can catch issues early.

These studies show that precision leveling is essential for success.

What are the benefits of lathe precision leveling?

The benefits include better accuracy, longer machine life, and improved product quality.

Future Trends in Lathe Automation and Precision Leveling

Emerging technologies in lathe automation. Predictions for the future of precision leveling in machining.New tools in lathe automation are changing how we work with machines. Smart machines will soon use sensors and AI to do tasks faster and more accurately. This means that precision leveling will improve. Here are some predictions:

- Machines will be more self-sufficient.

- We will see better accuracy in measurements.

- Fewer mistakes will lead to less waste and lower costs.

As technology grows, the future looks bright for lathes and their role in manufacturing. Expect advancements that will make our jobs easier.

What is the future of precision leveling in machining?

The future of precision leveling is focused on using smart technology to enhance performance and accuracy. Machines will adapt and learn, which makes them smarter every day. This is exciting for everyone in the industry!

Conclusion

In conclusion, lathe precision leveling is essential for accurate metalworking. Automation helps improve efficiency and reduce errors. By understanding these concepts, you can enhance your skills and create better projects. We encourage you to explore more about lathe techniques and try implementing automation in your work. Keep learning, and soon you will master metal lathe techniques!FAQs

What Are The Best Practices For Achieving Precision Leveling Of A Metal Lathe In An Automated Manufacturing Environment?To achieve precision leveling of a metal lathe, start by placing it on a sturdy and flat surface. Next, use a level tool to check if the machine is straight. Adjust the feet of the lathe to make it level. After that, double-check with the level tool again to make sure it’s just right. Finally, tighten everything so it stays in place while we work.

How Does The Leveling Of A Lathe Influence The Accuracy And Consistency Of Automated Machining Processes?When we level a lathe, it helps the machine stay straight and steady. This means the parts we make are more accurate and fit together better. If the lathe isn’t level, it can cause mistakes. So, keeping it level is important for good work. We want parts that are the same every time!

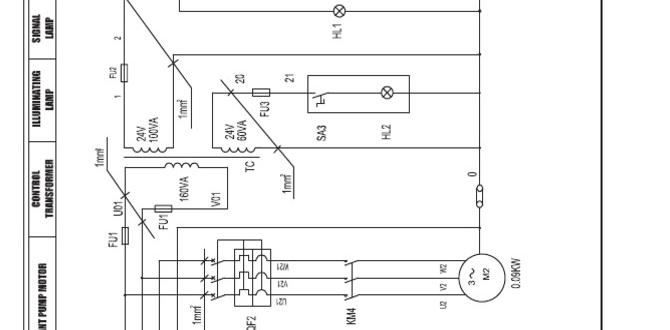

What Tools And Technologies Are Available For Automating The Precision Leveling Of Metal Lathes?To automate the precision leveling of metal lathes, we can use special tools like laser levels and electronic sensors. Laser levels help us see if the lathe is straight and even. Electronic sensors can measure small changes and tell us how to adjust the lathe. There are also computer programs that help control and check these machines. Using these tools makes it easier to keep everything just right.

How Can Sensors And Feedback Systems Be Integrated Into Lathe Automation To Ensure Ongoing Precision Leveling During Operation?We can use sensors to check the lathe’s position while it works. These sensors can tell when something is off or not straight. If they find a problem, they send a signal to a feedback system. The system then makes small adjustments to keep everything level. This way, the lathe keeps working correctly and makes precise pieces.

What Are The Common Challenges Faced In Maintaining Precision Leveling In Automated Metal Lathes, And How Can They Be Overcome?One common challenge is that machines can shake when they work. This shaking changes how well they cut metal. We can fix this by putting heavy weights on the machine’s feet. Another issue is dirt and dust buildup, which can also affect precision. We can clean the machines regularly to keep them working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Achieving Precision Leveling Of A Metal Lathe In An Automated Manufacturing Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling of a metal lathe, start by placing it on a sturdy and flat surface. Next, use a level tool to check if the machine is straight. Adjust the feet of the lathe to make it level. After that, double-check with the level tool again to make sure it’s just right. Finally, tighten everything so it stays in place while we work.”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Lathe Influence The Accuracy And Consistency Of Automated Machining Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we level a lathe, it helps the machine stay straight and steady. This means the parts we make are more accurate and fit together better. If the lathe isn’t level, it can cause mistakes. So, keeping it level is important for good work. We want parts that are the same every time!”}},{“@type”: “Question”,”name”: “What Tools And Technologies Are Available For Automating The Precision Leveling Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To automate the precision leveling of metal lathes, we can use special tools like laser levels and electronic sensors. Laser levels help us see if the lathe is straight and even. Electronic sensors can measure small changes and tell us how to adjust the lathe. There are also computer programs that help control and check these machines. Using these tools makes it easier to keep everything just right.”}},{“@type”: “Question”,”name”: “How Can Sensors And Feedback Systems Be Integrated Into Lathe Automation To Ensure Ongoing Precision Leveling During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use sensors to check the lathe’s position while it works. These sensors can tell when something is off or not straight. If they find a problem, they send a signal to a feedback system. The system then makes small adjustments to keep everything level. This way, the lathe keeps working correctly and makes precise pieces.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced In Maintaining Precision Leveling In Automated Metal Lathes, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “One common challenge is that machines can shake when they work. This shaking changes how well they cut metal. We can fix this by putting heavy weights on the machine’s feet. Another issue is dirt and dust buildup, which can also affect precision. We can clean the machines regularly to keep them working well.”}}]}