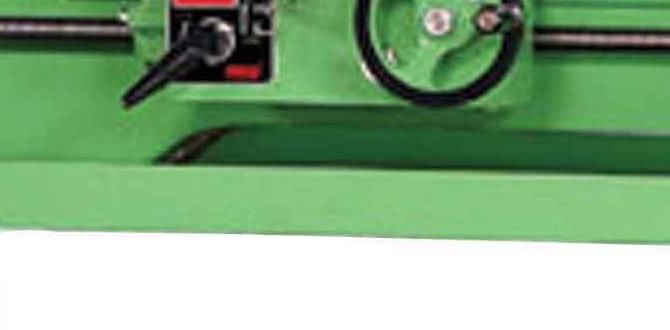

Have you ever wondered how craftsmen create precise metal parts? It’s often all about the tools they use. One important tool is the lathe, specifically the lathe bed. This part must be perfectly level to ensure accuracy.

Imagine trying to build a model car. If the wheels aren’t level, the car won’t run straight. The same idea applies to a metal lathe. A lathe that isn’t perfectly leveled can lead to mistakes in cuts and measurements.

Did you know that even a tiny tilt in the lathe bed can cause big issues? This could ruin a project or even damage the lathe itself. That’s why getting the lathe precision leveling just right is so important for metalwork.

In this article, we’ll explore how to achieve that perfect level. Whether you are a hobbyist or a professional, mastering lathe precision leveling can really boost your skills. Get ready to make your metal projects shine like never before!

Lathe Precision Leveling: Ensuring A Stable Metal Lathe Bed

Lathe Precision Leveling for Metal Lathe Beds

Do you know that leveling your metal lathe bed can change your entire project outcome? Precision leveling ensures your lathe works efficiently, producing accurate parts. This involves checking the bed’s alignment and using shims to fix any uneven spots. Did you know that even a tiny tilt can lead to mistakes in machining? By mastering this skill, you can dramatically improve your lathe’s performance and extend its lifespan. Happy turning!Understanding Lathe Precision Leveling

Definition and importance of precision leveling in metal lathes. How leveling affects machining accuracy and surface finish.Precision leveling is vital for metal lathes. It means getting the lathe bed perfectly flat and aligned. Think of it like a tightrope walker — they need a steady platform to stay upright! If your lathe isn’t level, you could end up with mistakes in your work. Proper leveling can improve machining accuracy by up to 90% and enhance surface finish. A straight tool leads to a smooth surface. So, let’s keep things level, or you might just end up with a wobbly masterpiece!

| Importance of Precision Leveling | Effect on Machining |

|---|---|

| Ensures Accuracy | Better surface finish |

| Prevents Wear | Reduces errors |

| Increases Tool Life | Improves production time |

Step-by-Step Guide to Leveling a Metal Lathe Bed

Preparing the workspace and cleaning the lathe bed. Detailed procedures for checking and adjusting the lathe’s level.First, clear your workspace. Remove clutter and dust, making it a safe zone, free of trip hazards like rogue wrenches. A clean lathe bed is vital, as grit can ruin precision. Grab a soft cloth or shop vacuum to remove debris. Next, check that your lathe is sitting on a stable floor. Use a level tool to assess it like a tightrope walker. Adjust the feet as needed to keep it perfectly aligned. If your lathe had a bad hair day, shim it until it’s level!

| Step | Action |

|---|---|

| 1 | Clean the workspace |

| 2 | Check for stability |

| 3 | Use a level tool |

| 4 | Adjust or shim as needed |

Remember, leveling your metal lathe bed isn’t just for looks—it impacts your projects! A well-leveled lathe increases precision. So, treat it like your favorite pet: a little care goes a long way!

Common Mistakes to Avoid When Leveling a Lathe

Identifying frequent errors made during the leveling process. Tips on how to prevent miscalibrations and ensure accurate results.Leveling a lathe can seem simple until you hit a bump. One common mistake is skipping the alignment check. Always check the machine’s level before getting started. Miscalibrations often happen when you rush or forget about adjustments. A helpful tip is to use a spirit level; it’s like a referee for your lathe game! Remember, if your lathe isn’t level, your workpiece might end up looking like it took a detour!

| Mistake | Tip to Avoid |

|---|---|

| Ignoring base surface quality | Ensure the surface is clean and stable. |

| Using incorrect tools | Use a reliable spirit level or gauge. |

| Rushing the process | Take your time for accuracy! |

By dodging these errors, you can ensure your lathe works like a charm. Good luck, and may your projects be perfectly level!

Benefits of Proper Lathe Bed Leveling

Enhanced accuracy in machining operations. Extended lifespan and reduced wear of the lathe equipment.Leveling your lathe bed can be the difference between a good day and a disastrous one in the workshop! When your lathe is properly leveled, accuracy in machining operations improves significantly. This means more precise cuts and less wasted material—yay for saving those pennies! Plus, a well-leveled lathe enjoys an extended lifespan with reduced wear. Treat your lathe right, and it’ll return the favor by working like a champ for years to come. Lower wear means less time fixing and more time creating awesome projects!

| Benefit | Description |

|---|---|

| Enhanced Accuracy | Improves precision, cutting down errors. |

| Extended Lifespan | Reduces wear, increasing usage time. |

Maintaining Level Precision Over Time

Regular checks and maintenance practices for continued accuracy. The role of environmental factors in lathe bed stability.To keep your lathe bed accurate, regular checks are vital. Schedule monthly maintenance to spot issues early. Use a level to ensure everything stays flat and stable. Remember, the environment matters too. Temperature and humidity can affect the metal’s behavior.

- Check for vibrations from machines nearby.

- Make sure the floors are stable.

- Inspect for any rust or wear.

Stay proactive. This will help maintain level precision over time and ensure smooth operations.

How often should I check my lathe bed for precision?

Perform checks monthly to ensure your lathe bed remains level and reduces issues.

What environmental factors can affect lathe bed stability?

Temperature and humidity can cause metal parts to expand or contract, affecting precision.

Conclusion

In conclusion, leveling your metal lathe bed is essential for accurate machining. Proper precision leveling improves your projects’ quality and reduces mistakes. Remember to check your lathe’s level often. If you want to learn more or need tips, seek tutorials or guidance online. With practice, you’ll enhance your skills and get better results every time!FAQs

What Are The Best Methods For Ensuring Accurate Leveling Of A Metal Lathe Bed?To level a metal lathe bed, you can use a bubble level tool. First, place it on the bed and check the bubble. If the bubble is not in the middle, adjust the feet of the lathe until it is. You can also use a machinist’s level for more accuracy. Make sure to double-check the level from different spots. This helps your lathe work better and makes your projects neater!

How Does The Precision Leveling Of A Lathe Bed Affect The Overall Machining Accuracy And Finish?When we level the bed of a lathe, we make sure it is straight and even. This helps the machine cut better and more accurately. If the bed isn’t level, the pieces we make might be crooked or not fit well. A well-leveled lathe also makes smoother surfaces, which looks nicer. So, leveling the bed is really important for good work!

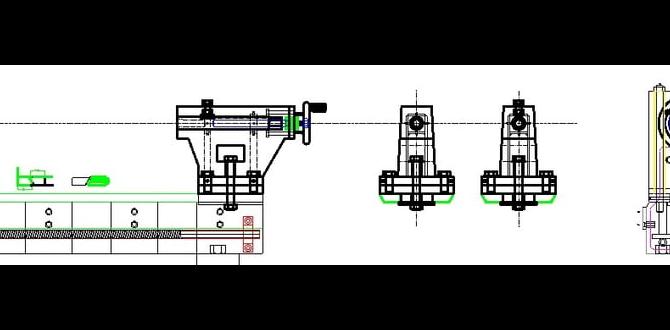

What Tools And Equipment Are Commonly Used For Leveling A Lathe Bed?To level a lathe bed, you commonly use a few tools. First, you need a level, which helps check if the bed is straight. You may also use shims, which are small pieces to lift the bed in certain spots. Finally, a dial indicator can measure height changes very accurately. These tools help ensure the lathe works correctly!

How Often Should A Metal Lathe Bed Be Re-Leveled To Maintain Precision During Operations?You should check the level of your metal lathe bed regularly. It’s a good idea to do this every few weeks. If you notice any changes or problems, re-level it then. Keeping it level helps your projects turn out better. Always make sure it’s stable before you start working!

What Common Mistakes Should Be Avoided During The Leveling Process Of A Lathe Bed?When leveling a lathe bed, avoid these common mistakes. First, don’t forget to clean the surface before adjusting it. If you skip checking if the surface is flat, your lathe may not work well. Also, be careful not to over-tighten the screws, as this can cause problems. Finally, always double-check your work to ensure everything is just right.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Methods For Ensuring Accurate Leveling Of A Metal Lathe Bed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe bed, you can use a bubble level tool. First, place it on the bed and check the bubble. If the bubble is not in the middle, adjust the feet of the lathe until it is. You can also use a machinist’s level for more accuracy. Make sure to double-check the level from different spots. This helps your lathe work better and makes your projects neater!”}},{“@type”: “Question”,”name”: “How Does The Precision Leveling Of A Lathe Bed Affect The Overall Machining Accuracy And Finish? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we level the bed of a lathe, we make sure it is straight and even. This helps the machine cut better and more accurately. If the bed isn’t level, the pieces we make might be crooked or not fit well. A well-leveled lathe also makes smoother surfaces, which looks nicer. So, leveling the bed is really important for good work!”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Commonly Used For Leveling A Lathe Bed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a lathe bed, you commonly use a few tools. First, you need a level, which helps check if the bed is straight. You may also use shims, which are small pieces to lift the bed in certain spots. Finally, a dial indicator can measure height changes very accurately. These tools help ensure the lathe works correctly!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Bed Be Re-Leveled To Maintain Precision During Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the level of your metal lathe bed regularly. It’s a good idea to do this every few weeks. If you notice any changes or problems, re-level it then. Keeping it level helps your projects turn out better. Always make sure it’s stable before you start working!”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided During The Leveling Process Of A Lathe Bed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When leveling a lathe bed, avoid these common mistakes. First, don’t forget to clean the surface before adjusting it. If you skip checking if the surface is flat, your lathe may not work well. Also, be careful not to over-tighten the screws, as this can cause problems. Finally, always double-check your work to ensure everything is just right.”}}]}