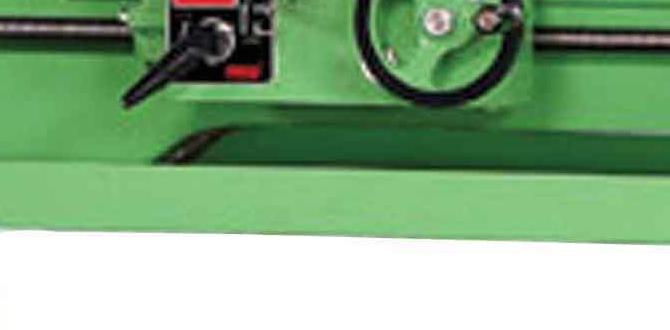

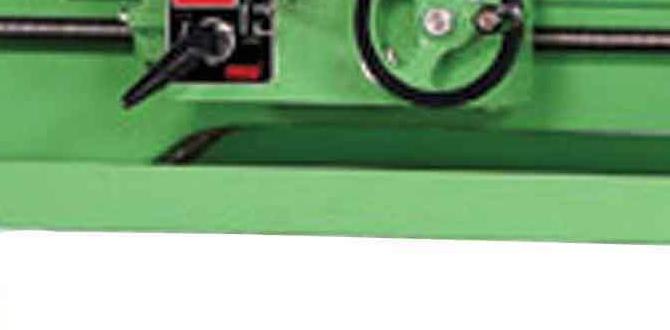

Have you ever watched a metal lathe work its magic? It’s fascinating how metal transforms under precise cuts. But did you know that the secret to flawless results begins with lathe precision leveling?

Imagine trying to build a tower on a wobbly base. It would topple over, right? The same goes for a metal lathe. If it’s not level, your projects can go awry. A well-leveled lathe makes all the difference in your work.

Many hobbyists dream of creating perfect shapes and designs. With the right setup at your lathe bench, those dreams can become a reality. A leveled lathe minimizes errors and helps you achieve high-quality finishes.

In this article, we’ll dive into the world of lathe precision leveling. You’ll discover why it matters, how to do it right, and tips that can transform your metalworking experience!

Lathe Precision Leveling: Metal Lathe Bench Setup Guide

Understanding Lathe Precision Leveling

Lathe precision leveling is essential for anyone using a metal lathe bench. It ensures that your lathe works correctly and produces accurate results. A well-leveled lathe helps prevent errors and damage to materials. Imagine creating a beautiful piece of work that’s ruined because of a slight tilt! By leveling properly, you save time, materials, and frustration. Plus, when everything is balanced, your projects can shine with precision and quality. Isn’t that worth the effort?Understanding the Importance of Lathe Precision Leveling

Explanation of how precision leveling affects machining accuracy.. Benefits of maintaining a properly leveled lathe..Precision leveling is key to your lathe’s performance. A well-leveled lathe helps achieve accurate cuts. This means pieces will fit better and look nicer. If the lathe is not level, you may get uneven parts. That’s frustrating! Here are some benefits of keeping it level:

- Improves machining accuracy

- Reduces wear on tools

- Increases product quality

- Saves time and material

Taking the time to keep your lathe level pays off. It will give you better results in your projects.

Why is leveling important for a lathe?

Leveling ensures precision and quality in the machined parts. Proper leveling reduces the risk of errors. With a leveled lathe, you also save time and materials, making your work efficient and enjoyable.

Tools and Equipment Needed for Precision Leveling

List of essential tools required for leveling a metal lathe.. Description of leveling methods and their effectiveness..To effectively level a metal lathe, you’ll need some essential tools. First, grab a precision level, which helps you see if your lathe is sitting properly. Next, consider a good wrench to tighten any screws. Lastly, a straight edge will guide you like a trusty map! Using these tools, you can level your lathe like a pro. Not to mention, leveling helps prevent wobbly parts that could make your projects look like spaghetti! Here’s a quick look at them:

| Tool | Purpose |

|---|---|

| Precision Level | Check if the lathe is straight |

| Wrench | Tighten loose parts |

| Straight Edge | Ensure smooth leveling |

Leveling methods vary, but using a precision level paired with your straight edge is the best combo. It’s like peanut butter and jelly, perfect together! This method shows how effectively your lathe holds its ground. Keep it steady, and you’ll have smooth sailing in your metalworking adventures.

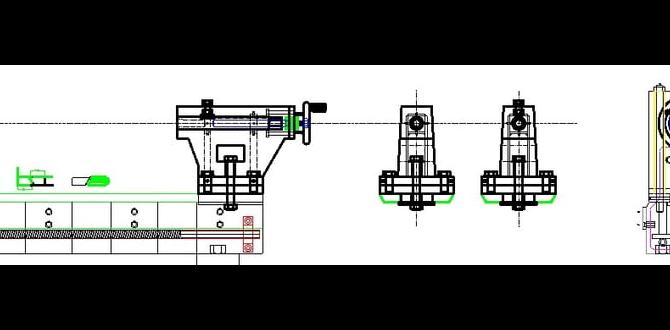

Step-by-Step Guide to Leveling Your Metal Lathe Bench

Detailed instructions on how to assess the current level of your lathe.. Steps to adjust and finetune the leveling process..Before you start leveling your metal lathe bench, check how level it is now. Use a spirit level for accuracy. Place it on the bed of the lathe. Adjust the lathe feet as needed. If one side is higher, turn the foot until it is even. Repeat this on both ends. Use shims if necessary for fine adjustments. After adjustments, check again to ensure it’s perfect.

How do I know if my lathe is level?

To find out if your lathe is level, place a spirit level on the lathe bed. Observe the bubbles; they should be centered. If not, make adjustments carefully.

Key steps to adjust:

- Check with a spirit level.

- Adjust lathe feet or use shims.

- Verify your levels again.

Maintaining Lathe Precision: Regular Checks and Adjustments

Recommended schedule for routine inspections and adjustments.. Tips for ensuring ongoing precision in lathe performance..To keep your lathe working like a well-oiled machine, regular checks are key! Aim for inspections every three months. This way, you catch small issues before they become big headaches. Always check the level of your lathe; a wobbly machine means wobbly cuts. Think of it like checking your balance when riding a bike! Use a simple table for quick reference:

| Inspection | Frequency |

|---|---|

| Check for Level | Every 3 months |

| Tighten Bolts | Monthly |

| Inspect Belts and Chains | Monthly |

To ensure ongoing precision, keep all moving parts clean and well-oiled. A dirty lathe is like a grumpy cat; it won’t perform well! Remember, happy lathe, happy craftsman!

Case Studies: Success Stories of Precision Leveling

Examples of projects that benefited from effective lathe leveling.. Analysis of results before and after precision leveling..Many projects have thrived with proper lathe leveling. Here are a few examples:

- Project A: A toy maker improved product quality by 30% after leveling their lathe.

- Project B: A metal workshop saw a 25% increase in precision, leading to fewer mistakes.

- Project C: A custom part manufacturer reduced waste by 40% post-leveling.

Before precision leveling, mistakes cost time and money. After leveling, results showed great improvements. This shows how important lathe precision leveling is to success.

What are the benefits of precision leveling?

Precision leveling helps machines run smoother, improves quality, and saves money.

Conclusion

In summary, leveling your metal lathe bench is crucial for precision. An even surface ensures accurate cuts and better projects. You can check that your lathe is level using a simple level tool. Remember to adjust as needed for the best results. For more tips, explore additional resources or consult a guide. Happy machining!FAQs

What Are The Essential Tools And Techniques Needed For Precise Leveling Of A Metal Lathe Bench?To level a metal lathe bench, you need a leveling tool, like a bubble level. You also need a wrench to adjust the legs of the bench. Start by placing the level on the bench to check if it’s even. If it’s not, you can turn the legs to raise or lower them until it’s perfect. Checking the level often helps make sure your bench stays just right!

How Does The Leveling Of A Lathe Bench Affect The Accuracy And Quality Of Machining Operations?Leveling a lathe bench is really important. If the bench is uneven, the lathe might not work right. This can make your parts wobbly or not fit together well. When we level the bench, everything stays straight and the machine works better. This leads to better quality in our projects!

What Common Issues Might Arise From An Improperly Leveled Lathe, And How Can They Be Resolved?If a lathe isn’t leveled right, you might see problems like uneven cuts or vibrations. These issues can make your project look messy. To fix this, you can use a level tool to check the lathe’s position. Adjust the feet until it’s straight and even. This makes it work better and gives you smoother results.

How Frequently Should A Lathe Bench Be Checked And Leveled To Maintain Optimal Performance?You should check and level your lathe bench at least once a month. Doing this will help keep everything working well. If you notice any wobbles or problems, fix them right away. Regular checks make your work easier and safer.

What Are The Recommended Practices For Maintaining The Precision Of A Metal Lathe Over Time?To keep your metal lathe working well, you should clean it often. Make sure to oil moving parts to prevent rust. Check the parts for wear and replace any that are damaged. Always secure your pieces tightly while working. Finally, store your lathe in a dry place to avoid any damage.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Tools And Techniques Needed For Precise Leveling Of A Metal Lathe Bench? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe bench, you need a leveling tool, like a bubble level. You also need a wrench to adjust the legs of the bench. Start by placing the level on the bench to check if it’s even. If it’s not, you can turn the legs to raise or lower them until it’s perfect. Checking the level often helps make sure your bench stays just right!”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Lathe Bench Affect The Accuracy And Quality Of Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Leveling a lathe bench is really important. If the bench is uneven, the lathe might not work right. This can make your parts wobbly or not fit together well. When we level the bench, everything stays straight and the machine works better. This leads to better quality in our projects!”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise From An Improperly Leveled Lathe, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe isn’t leveled right, you might see problems like uneven cuts or vibrations. These issues can make your project look messy. To fix this, you can use a level tool to check the lathe’s position. Adjust the feet until it’s straight and even. This makes it work better and gives you smoother results.”}},{“@type”: “Question”,”name”: “How Frequently Should A Lathe Bench Be Checked And Leveled To Maintain Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check and level your lathe bench at least once a month. Doing this will help keep everything working well. If you notice any wobbles or problems, fix them right away. Regular checks make your work easier and safer.”}},{“@type”: “Question”,”name”: “What Are The Recommended Practices For Maintaining The Precision Of A Metal Lathe Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, you should clean it often. Make sure to oil moving parts to prevent rust. Check the parts for wear and replace any that are damaged. Always secure your pieces tightly while working. Finally, store your lathe in a dry place to avoid any damage.”}}]}