Have you ever wondered how things are made with perfect precision? One tool that helps in achieving this is the lathe. A lathe can shape metal into amazing objects. But did you know that the lathe’s precision depends heavily on how well it is leveled? That’s right! The lathe precision leveling is a crucial step that can make or break your project.

Imagine trying to bake a cake on a wobbly table. The cake may not turn out well, right? Similarly, if a metal lathe carriage is not level, it can lead to inaccuracies in your work. This can be frustrating, especially when you’re aiming for perfection.

People often overlook the importance of leveling their lathe. It’s a simple step but very important. By leveling your lathe properly, you can avoid many common problems. This small adjustment can lead to a smoother and more successful machining experience.

In this article, we will explore how to achieve perfect lathe precision leveling on your metal lathe carriage. Get ready to unlock the secret to better craftsmanship!

Lathe Precision Leveling Of Metal Lathe Carriage: Essential Guide

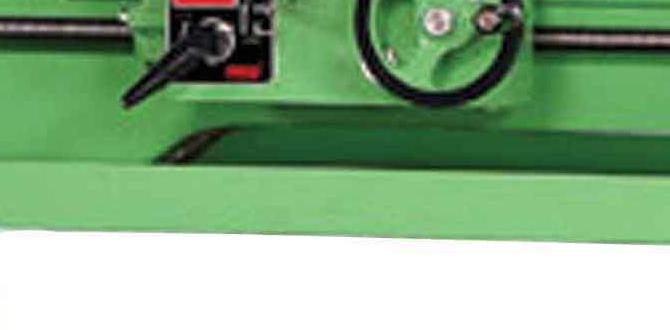

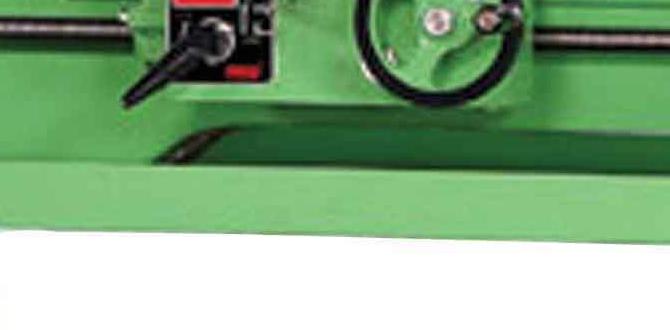

Lathe Precision Leveling Metal Lathe Carriage

Do you wonder how metal lathes achieve smooth cuts? Precision leveling is key. A well-leveled lathe carriage ensures accuracy and prevents errors in your work. Did you know that even a tiny tilt can affect your cuts? By leveling your lathe correctly, you can create better parts and save time. This process helps minimize wear and tear on your tools too. Discovering this craft can make your projects more successful and enjoyable!Understanding Lathe Precision

Definition and importance of precision in metal lathes. Factors affecting lathe precision.Precision in metal lathes is about making exact cuts. It helps create smooth and perfect pieces. High precision can lead to better quality work. Many factors affect this precision, like the machine’s condition, tool sharpness, and alignment. If the machine is not level, it can cause mistakes.

- Machine maintenance

- Tool wear and sharpness

- Carriage alignment

Keeping these factors in check is key for good results. Remember, in lathe work, every detail matters!

Why Is Lathe Precision Important?

Lathe precision is key for creating accurate parts. It helps in producing pieces that fit perfectly, which is essential in various industries like automotive and aerospace. A precise lathe means fewer errors and waste.

Step-by-Step Guide to Leveling a Metal Lathe Carriage

Initial assessments and preleveling checks. Detailed leveling process broken down into actionable steps.Before you dive into leveling your metal lathe carriage, take a moment to check a few things. First, ensure your lathe is on a solid surface. A wobbly table is bad news! Next, examine the base of your lathe for any visible damage or dirt. Remember, a clean machine runs like a happy puppy. Now, let’s break down the leveling process:

| Step | Description |

|---|---|

| 1 | Use a precision level on the bed; adjust if needed. |

| 2 | Check the carriage movement; it should glide smoothly! |

| 3 | Make fine adjustments with leveling screws. |

| 4 | Re-check the level and test the carriage again. |

Following these steps can turn a grumpy lathe into a precision tool. Happy leveling!

Common Issues with Lathe Carriage Leveling

Identifying typical problems and their causes. Solutions for overcoming these challenges.Lathe carriage leveling can bring some funny headaches. Common problems include uneven cuts and stray vibrations. These happen because the lathe isn’t sitting flat or has worn-out parts. Luckily, solutions are at hand! First, check the base for level using a good ol’ bubble level. If it tilts more than your friend trying to balance on a ball, you need to adjust it. Also, replace any old components to keep things smooth. Here’s a quick table to help you:

| Problem | Cause | Solution |

|---|---|---|

| Uneven Cuts | Unlevel base | Use a level tool to adjust |

| Stray Vibrations | Worn-out parts | Replace old components |

Maintaining Optimal Lathe Precision

Best practices for regular maintenance. Tips for ensuring sustained precision over time.Keeping your lathe in shape is like giving it a spa day! Regular maintenance is key. Check the oil levels often. A happy lathe runs smoother. Clean the carriage and bed to remove chips and dust; they’re like a lathe’s version of pesky crumbs. Adjust the leveling often to keep things precise.

| Best Practice | Tip |

|---|---|

| Check Oil Levels | Use a dipstick – it’s the lathe’s version of checking your pulse! |

| Clean Regularly | Dust and chips can mess with precision. Think of it as spring cleaning! |

| Leveling Adjustments | Little tweaks mean a lot! A straight line is a happy line. |

By following these tips, you’ll ensure your lathe remains precise and ready for action. Happy turning!

FAQs about Lathe Precision Leveling

Common questions and expert answers. Tips for troubleshooting specific issues related to carriage leveling.Wondering about leveling your lathe? Here are some common questions and answers that can help smooth out your metalworking journey. First, you might ask, “How do I know if my carriage is level?” Well, a quick check with a bubble level can save you from wobbly workpieces! If your cuts aren’t precise, the issue could be a tilted carriage. An unexpected gap may also happen. Remember, adjusting those leveling screws can work wonders. No magic wand needed!

| Question | Answer |

|---|---|

| What is the best way to level my lathe? | Use a precision level and adjust the feet until it’s perfect! |

| How often should I check my lathe’s level? | Before major projects or if your lathe moves! |

Conclusion

In summary, leveling your metal lathe carriage is crucial for precision work. When you level correctly, your projects will turn out better. Remember, a stable setup reduces errors. We encourage you to practice these tips on your own lathe. For more details, check out additional resources or guides. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically Focusing On Metal Lathe Carriage:Sure! Leveling a metal lathe carriage helps it to work better. You need to check if it is straight. Use a level tool to help you see if it’s even. If it’s not, you can adjust the feet until it is. This makes your machine more accurate when cutting metal.

Sure! Please provide the question you would like me to answer.

What Are The Key Indicators To Assess Whether A Metal Lathe Carriage Is Properly Leveled?To check if a metal lathe carriage is level, you can look for a few key things. First, use a level tool. Place it on the carriage. If the bubble is in the center, it’s level. Second, check if the carriage moves smoothly back and forth. If it sticks or wobbles, it might not be level. Finally, make sure there are no gaps between the carriage and the bed of the lathe.

How Does Improper Leveling Of The Lathe Carriage Affect The Accuracy Of Machining Operations?If the lathe carriage isn’t level, it can make the cutting tools wobble. This wobbling means that the machine won’t cut straight or smooth. You might end up with parts that don’t fit together right. Keeping everything level helps us make better pieces.

What Tools And Methods Are Commonly Used For Leveling A Metal Lathe Carriage?To level a metal lathe carriage, we often use a leveling tool, like a spirit level or a precision level. You can place it on the lathe to see if it’s balanced. If it’s not, we adjust the feet of the lathe. Sometimes, we use shims, which are small pieces of material, to help make it even. Checking the level can help our lathe work better!

How Often Should A Metal Lathe Carriage Be Checked And Adjusted For Precision Leveling?You should check the metal lathe carriage every few weeks. If you use it a lot, check it more often. Adjust it if you notice it isn’t cutting straight. Keeping it level helps make better parts. Always remember to be careful when doing this!

What Are The Potential Consequences Of Neglecting Precision Leveling In A Metal Lathe?If you don’t level the metal lathe correctly, it can cause problems. The metal pieces may not be cut straight. This means your projects won’t look or fit right. You could even damage the machine or hurt yourself. Always remember to check the leveling to keep everything safe and working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically Focusing On Metal Lathe Carriage:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Leveling a metal lathe carriage helps it to work better. You need to check if it is straight. Use a level tool to help you see if it’s even. If it’s not, you can adjust the feet until it is. This makes your machine more accurate when cutting metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Indicators To Assess Whether A Metal Lathe Carriage Is Properly Leveled?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a metal lathe carriage is level, you can look for a few key things. First, use a level tool. Place it on the carriage. If the bubble is in the center, it’s level. Second, check if the carriage moves smoothly back and forth. If it sticks or wobbles, it might not be level. Finally, make sure there are no gaps between the carriage and the bed of the lathe.”}},{“@type”: “Question”,”name”: “How Does Improper Leveling Of The Lathe Carriage Affect The Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe carriage isn’t level, it can make the cutting tools wobble. This wobbling means that the machine won’t cut straight or smooth. You might end up with parts that don’t fit together right. Keeping everything level helps us make better pieces.”}},{“@type”: “Question”,”name”: “What Tools And Methods Are Commonly Used For Leveling A Metal Lathe Carriage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe carriage, we often use a leveling tool, like a spirit level or a precision level. You can place it on the lathe to see if it’s balanced. If it’s not, we adjust the feet of the lathe. Sometimes, we use shims, which are small pieces of material, to help make it even. Checking the level can help our lathe work better!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Carriage Be Checked And Adjusted For Precision Leveling?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the metal lathe carriage every few weeks. If you use it a lot, check it more often. Adjust it if you notice it isn’t cutting straight. Keeping it level helps make better parts. Always remember to be careful when doing this!”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Neglecting Precision Leveling In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t level the metal lathe correctly, it can cause problems. The metal pieces may not be cut straight. This means your projects won’t look or fit right. You could even damage the machine or hurt yourself. Always remember to check the leveling to keep everything safe and working well.”}}]}