Imagine you’re in a workshop buzzing with activity. You can hear the gentle hum of machines, and the smell of metal fills the air. In the center of this busy space sits a metal lathe. It’s a powerful tool, shaping metal into precise parts. But what makes this lathe work so well? The answer lies in lathe precision leveling.

Have you ever wondered how a lathe can create perfect circles and smooth edges? The secret is in something simple yet vital: the metal lathe chuck. This small component plays a big role in gripping the metal tightly. It holds the piece steady while the lathe works its magic.

With correct leveling, the lathe operates efficiently. Imagine trying to write on a slope; it just won’t work right! Similarly, a metal lathe needs a flat surface. Precision leveling ensures that every turn is accurate. It can mean the difference between a good part and a great part. Wouldn’t you want to achieve great results every time?

This article explores the importance of lathe precision leveling and the role of the metal lathe chuck. You’ll learn tips to improve your own crafting skills. So, let’s dive in! Your next metal work could be your best one yet!

Lathe Precision Leveling: Enhancing Your Metal Lathe Chuck

Lathe Precision Leveling: The Importance of Metal Lathe Chuck

Leveling your metal lathe is critical for optimal performance. A well-leveled lathe helps avoid errors in precision work. Did you know that even a tiny tilt can lead to big mistakes? It can affect the quality of your projects. Using a reliable metal lathe chuck ensures the workpiece holds firmly. This simple tool can make a huge difference. Making sure everything is balanced leads to better results in your crafting. Why not check your setup today?Understanding Lathe Precision

Definition and importance of precision in lathe operations.. Key factors that influence lathe precision..Think of lathe precision as the superhero of metalworking! It ensures that every cut is spot-on and every piece fits like a glove. Without proper precision, your projects might end up looking like they were made during a 3rd-grade art class! Key factors influencing this precision include alignment, tool sharpness, and chuck stability. If your lathe isn’t level, it’s like trying to ride a unicycle on a tightrope—very wobbly!

| Factors | Impact |

|---|---|

| Alignment | Affects how straight your cuts are. |

| Tool Sharpness | Sharp tools make cleaner cuts. |

| Chuck Stability | Stable chucks hold workpieces safely! |

The Role of Leveling in Lathe Performance

How leveling affects machining accuracy.. Common problems caused by improper leveling..Leveling your lathe is like getting a good night’s sleep; if it’s not right, things can go haywire! When your lathe isn’t level, it can lead to poor machining accuracy. Your cuts may come out uneven, like a lopsided cake. Common problems include vibrations and misalignment, which can throw off your work. It’s essential to check the level, or your projects might just end up as awkward paperweights!

| Problem | Effect on Machining |

|---|---|

| Improper Leveling | Causes uneven cuts |

| Vibrations | Makes tools wear faster |

| Misalignment | Results in inaccurate dimensions |

So, keep that lathe level, and your projects will stay on track!

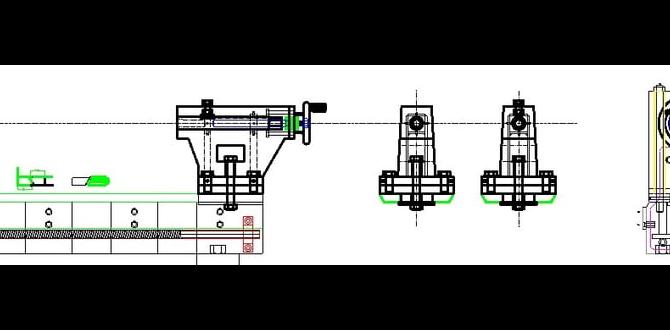

Choosing the Right Chuck for Your Metal Lathe

Types of chucks available and their specific applications.. Factors to consider when selecting a chuck for precision work..Choosing the right chuck for a metal lathe is important. Many types exist, each for specific uses. Here are common chucks:

- Four-jaw chuck: Great for irregular shapes.

- Three-jaw chuck: Best for round items.

- Collet chuck: Ideal for precision work.

When selecting a chuck, consider:

- Material: Stronger materials hold better.

- Size: Ensure it fits your lathe.

- Precision: Needed for detailed work.

With the right chuck, you can achieve great results!

What types of chucks are available for metal lathes?

Three-jaw, four-jaw, and collet chucks are the main types. Each serves different needs to help you work better.

Factors to consider for precision:

- Material quality: Strong materials offer better grip.

- Size compatibility: Make sure it fits your lathe.

- Precision ability: For the best results in detailed work.

Step-by-Step Guide to Leveling Your Metal Lathe

Tools and materials needed for effective leveling.. Detailed instructions for achieving optimal lathe leveling..To get your metal lathe leveled up like a pro, gather a few tools first. You’ll need a good level, some shims, and a wrench. Having a friend helps too. Now, carefully place the level on your lathe bed. Adjust it until the bubbles are just chilling in the center. If it’s off, slide in those shims until your lathe feels balanced. It’s like finding the perfect donut—just the right touch makes all the difference!

| Tools | Purpose |

|---|---|

| Level | Checks the balance |

| Shims | Adjusts the height |

| Wrench | Tightens loose parts |

Ensuring your lathe is level gives you better accuracy. A well-leveled machine means fewer mishaps and more happy projects. Remember, even the best lathe needs a little pampering now and then!

Calibration and Maintenance for Precision Stability

Importance of regular checks and calibration for lathe precision.. Maintenance tips to keep your metal lathe chuck in top condition..Regular checks for your lathe help keep it accurate. Calibration is key for precision. Without it, your work might not fit right. Good maintenance makes your metal lathe chuck last longer.

Here are some easy tips:

- Clean the lathe after each use.

- Check for any loose parts.

- Use quality oil for lubrication.

- Adjust the chuck as needed.

Why is calibration important?

Calibration ensures your lathe works right. Regular checks help catch problems early. It can save time and money.

Tips to keep your lathe chuck in top shape:

- Inspect the chuck regularly.

- Avoid hitting it with heavy tools.

Common Mistakes in Lathe Leveling and How to Avoid Them

Key mistakes that affect lathe precision and accuracy.. Practical tips to correct and prevent these mistakes..Keeping your lathe level can feel like rocket science, but it’s really just a balancing act. One big mistake is not checking your lathe precision before starting. If it’s off, your projects might end up looking like abstract art. To avoid this, always use a precision level tool each time you set up. Another common blunder is mismatching the chuck size. A small chuck on a big lathe? That’s like wearing clown shoes! Always choose the right size for accurate work. Check out the table below for quick tips:

| Mistake | How to Avoid It |

|---|---|

| Not using a level tool | Always check your lathe’s level before starting. |

| Wrong chuck size | Select the proper chuck size for your lathe. |

| Ignoring wear and tear | Regularly inspect and maintain your lathe. |

Impact of Environmental Factors on Lathe Precision

How temperature, humidity, and vibration affect lathe performance.. Strategies to mitigate environmental influences on machining..Environmental factors can greatly affect lathe performance. For instance, temperature changes can alter metal expansion, making cuts less precise. High humidity can cause rust and corrosion, impacting tool quality. Vibrations from nearby machines or floor movement can lead to inaccurate cuts.

To reduce these issues, consider these strategies:

- Use climate control to maintain a stable temperature.

- Place humidity controls in the workshop.

- Install vibration dampening systems.

How does temperature and humidity affect lathe precision?

Temperature changes lead to part expansion, which can affect accuracy. Humidity can cause rust, impacting tooling quality. Keeping these factors in check ensures better performance.

What are ways to reduce vibration impacts?

Support your lathe with sturdy surfaces. Keep the workspace organized to limit those vibrations.

Real-World Applications of Lathe Precision Leveling

Examples of industries relying on precise lathe operations.. Case studies showcasing the benefits of proper leveling..Many industries depend on precise lathe operations. For example, the automotive industry uses lathes to create parts that fit snugly together. This is crucial for cars to run smoothly—no one wants a wobbly wheel! The aerospace sector also relies on accurate lathe work, crafting components that keep planes safe and flying straight.

One case study showed that a proper leveling of lathe equipment improved accuracy by 25%. That’s like going from a shaky table to one that could serve your grandma’s best china! Proper leveling not only saves time but also cash by reducing waste. Here are a few industries that benefit:

| Industry | Benefit |

|---|---|

| Automotive | Improved part fit |

| Aerospace | Enhanced safety |

| Manufacturing | Lower waste costs |

In conclusion, precise lathe leveling is more than a fancy term; it’s about creating reliable products. The best part? It can save your wallet too!

Conclusion

In summary, using lathe precision leveling helps you achieve better results with your metal lathe chuck. Properly leveling ensures accurate cuts and smoother operations. Remember to check your levels regularly and adjust as needed. For better skills, practice more and read tutorials online. Now, you’re ready to start making precise, professional-quality projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For A Metal Lathe Chuck:When you want your lathe chuck to work well, you need to level it carefully. Use a tool called a level to check how straight it is. Adjust the legs of the lathe until it is perfectly flat. This helps make sure your work is smooth and accurate. A well-leveled lathe makes it easier to create great projects!

Sure! Please ask your question, and I’ll be happy to provide a short answer.

What Are The Key Steps Involved In Achieving Precise Leveling Of A Metal Lathe Chuck?To level a metal lathe chuck, you start by cleaning the surface where the chuck sits. Next, you place a level on top of the chuck to check its position. If it’s not level, you adjust the screws underneath to raise or lower it. Keep checking with the level until it’s even. Finally, tighten all the screws to make sure it stays level while you work.

How Does Precision Leveling Of A Lathe Chuck Impact The Accuracy Of Machining Operations?When you level a lathe chuck really well, it helps your machine cut parts more accurately. If the chuck is uneven, your cuts can be off. This means the pieces you make might not fit together right. By making sure everything is level, you get better results and save time fixing mistakes.

What Tools And Equipment Are Essential For Accurately Leveling A Metal Lathe Chuck?To level a metal lathe chuck, you need a few important tools. First, you’ll want a dial indicator. This tool measures how level the chuck is. You also need a set of leveling feet or screws to adjust the height. Lastly, a spirit level can help check if everything is straight. Using these tools will make your lathe work better.

How Can Misalignment In A Lathe Chuck Affect The Overall Performance And Results Of Machining Processes?If the lathe chuck isn’t lined up right, it can cause problems. The piece you are working on may wobble or spin unevenly. This can lead to cuts that aren’t straight or smooth. It makes your work look messy and not very good. So, it’s important to check that everything is lined up properly before starting.

What Troubleshooting Techniques Can Be Applied If A Metal Lathe Chuck Does Not Maintain Its Precision After Leveling?If your metal lathe chuck still isn’t accurate after leveling, you can check a few things. First, make sure the chuck is clean and free of any dirt. Next, look for loose screws or parts that need tightening. You can also check to see if the chuck is properly aligned with the lathe. Finally, if it still doesn’t work, you might need to ask for help from an adult or an expert.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For A Metal Lathe Chuck:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you want your lathe chuck to work well, you need to level it carefully. Use a tool called a level to check how straight it is. Adjust the legs of the lathe until it is perfectly flat. This helps make sure your work is smooth and accurate. A well-leveled lathe makes it easier to create great projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to provide a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Achieving Precise Leveling Of A Metal Lathe Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe chuck, you start by cleaning the surface where the chuck sits. Next, you place a level on top of the chuck to check its position. If it’s not level, you adjust the screws underneath to raise or lower it. Keep checking with the level until it’s even. Finally, tighten all the screws to make sure it stays level while you work.”}},{“@type”: “Question”,”name”: “How Does Precision Leveling Of A Lathe Chuck Impact The Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you level a lathe chuck really well, it helps your machine cut parts more accurately. If the chuck is uneven, your cuts can be off. This means the pieces you make might not fit together right. By making sure everything is level, you get better results and save time fixing mistakes.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Essential For Accurately Leveling A Metal Lathe Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe chuck, you need a few important tools. First, you’ll want a dial indicator. This tool measures how level the chuck is. You also need a set of leveling feet or screws to adjust the height. Lastly, a spirit level can help check if everything is straight. Using these tools will make your lathe work better.”}},{“@type”: “Question”,”name”: “How Can Misalignment In A Lathe Chuck Affect The Overall Performance And Results Of Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe chuck isn’t lined up right, it can cause problems. The piece you are working on may wobble or spin unevenly. This can lead to cuts that aren’t straight or smooth. It makes your work look messy and not very good. So, it’s important to check that everything is lined up properly before starting.”}},{“@type”: “Question”,”name”: “What Troubleshooting Techniques Can Be Applied If A Metal Lathe Chuck Does Not Maintain Its Precision After Leveling?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe chuck still isn’t accurate after leveling, you can check a few things. First, make sure the chuck is clean and free of any dirt. Next, look for loose screws or parts that need tightening. You can also check to see if the chuck is properly aligned with the lathe. Finally, if it still doesn’t work, you might need to ask for help from an adult or an expert.”}}]}