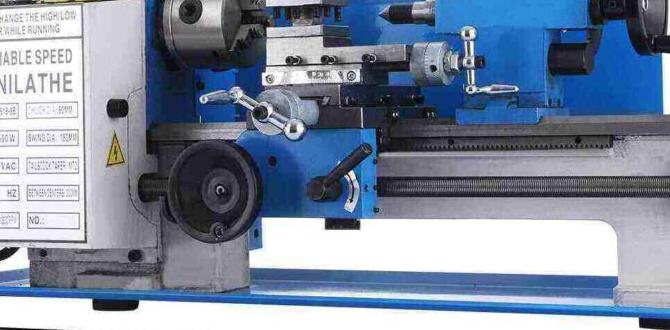

Have you ever wondered how precision in metalworking can make all the difference? Imagine a lathe that works perfectly, creating smooth, exact shapes. To achieve this, careful leveling is essential. It ensures that the machine functions correctly and produces accurate results.

One vital tool in this process is the lathe chuck key. It may seem small, but it plays a critical role. Together, lathe precision leveling and the chuck key help maintain the perfect grip on the workpiece during machining. Without them, even the best machines can struggle.

Did you know that a well-leveled lathe can improve the quality of your projects? It can save you time and materials. When everything aligns perfectly, your work shines. This article will explore the importance of lathe precision leveling and how using a proper metal lathe chuck key can lead to impressive results.

Lathe Precision Leveling: Essential Metal Lathe Chuck Key Guide

Lathe Precision Leveling Metal Lathe Chuck Key

Understanding lathe precision leveling is crucial for quality machining. A metal lathe chuck key helps secure workpieces firmly. Did you know that proper leveling can reduce errors and improve accuracy? It plays a vital role in creating smooth and precise cuts. Without leveling, your projects might end up uneven and inconsistent. Use the chuck key correctly to ensure your lathe operates at its best. Balanced equipment means better results every time!Understanding Lathe Precision

Definition of lathe precision and its importance in machining.. Factors affecting lathe precision including alignment and setup..Lathe precision means how accurately a lathe can shape metal. It is important because it helps create parts that fit together perfectly. This accuracy depends on several factors:

- Alignment: The lathe must be set up in a straight line.

- Setup: Tools need to be properly fixed and adjusted.

- Calibration: Regular checks ensure everything works well.

Without proper lathe precision, parts can be useless. That is why engineers pay close attention to these details.

Why is lathe precision important?

Lathe precision matters because it determines how well parts will function together. A small mistake can lead to big problems in machines. Proper setup leads to better quality pieces and fewer errors.

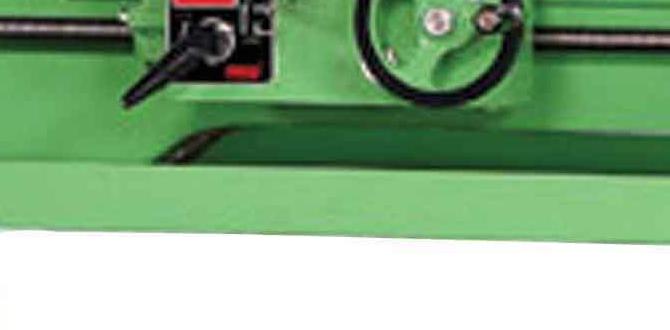

The Role of a Metal Lathe Chuck Key

Explanation of what a chuck key is and its functionality.. Types of chuck keys available for different lathe models..A chuck key is a small tool used with a metal lathe. It helps tighten or loosen the chuck, which holds the workpiece. Without it, pieces can slip or fall off during work. Different lathe models need different chuck keys to fit properly. Here are some types:

- Keyed Chuck Keys: Most common and secure for gripping.

- Keyless Chuck Keys: Easier to use, no key needed.

- Universal Chuck Keys: Fit various lathe models.

Choosing the right chuck key is important for safety and accuracy.

What is the purpose of a chuck key?

The primary purpose of a chuck key is to quickly and securely hold the workpiece in place while the lathe operates. This ensures the project is done safely and correctly.

Importance of Precision Leveling in Metal Lathes

How precise leveling influences cutting accuracy and tool wear.. Methods for achieving accurate leveling in metal lathes..Precision leveling is like putting on your favorite pair of shoes before a big race. It ensures everything is set for success! When a metal lathe is perfectly leveled, cutting accuracy improves. This means smoother finishes and less tool wear, which saves money. To achieve accurate leveling, you can use spirit levels or digital indicators. Think of these tools as your trusty companions on the quest for perfect cuts! Experts say even a small leveling error can lead to big problems—kind of like missing a step while dancing!

| Method | Description |

|---|---|

| Spirit Level | Check the lathe’s surface with a bubble leveling tool. |

| Digital Indicator | Use a digital tool for precise measurements. |

Steps to Level Your Metal Lathe

Tools required for leveling a lathe.. Detailed stepbystep guide to achieving precision leveling..Using a metal lathe requires careful setup. To level your lathe, you will need a few tools. First, grab a level. A ruler or tape measure works well too. You will also need a lathe precision leveling check for the best results. Start by placing the level across the lathe bed. Adjust the feet until it is perfectly horizontal. Repeat this process at different points. It may take a few tries, but accuracy is key!

What tools are needed for leveling a lathe?

Essential tools include:

- Level

- Ruler or tape measure

- Lathe precision leveling check

- Wrench for adjusting feet

This check ensures your lathe runs smoothly, reducing wear and improving performance.

Maintenance Tips for Chuck Keys

Best practices for maintaining and storing chuck keys.. Signs of wear and when to replace your chuck key..Taking care of your chuck keys is key to keeping things running smoothly! First, always store them in a dry place. Moisture can turn them into rusty little monsters. Look out for any signs of wear, like bending or rough edges. If your key starts acting more wobbly than a puppy on ice, it’s time for a change. Regularly check your tools to avoid any “key” disasters!

| Tip | Details |

|---|---|

| Store Properly | Keep in a dry, safe place. |

| Check for Wear | Look for bends or rough spots. |

| Replace on Time | If it wobbles, it’s time to go! |

Enhancing Lathe Performance with Accessories

Additional accessories that improve precision and efficiency.. How to choose the right accessories for your specific lathe..Using the right accessories can boost your lathe’s performance like adding nitro to a go-kart! Tools like precision leveling devices and durable chuck keys can make a big difference. They help your lathe run smoother and produce better finishes. To pick the best accessories, check your lathe model and consider your projects. It’s like choosing toppings for pizza; you want the right combination to make it delicious!

| Accessory | Benefit |

|---|---|

| Precision Leveling Kit | Ensures your lathe is perfectly level, improving accuracy. |

| Chuck Key | Helps securely grip workpieces, enhancing safety. |

| Tool Holder | Makes tool changes quicker and easier. |

So, before whipping up that metal masterpiece, gather some great accessories!

Real-World Applications of Precision Leveling and Chuck Keys

Examples of industries that rely on precision leveling in lathe operations.. Case studies showcasing the impact of proper chuck key usage on productivity..Many industries depend on precision leveling and chuck keys in lathe operations. Here are some examples:

- Manufacturing: Precise leveling ensures machines work correctly to produce accurate parts.

- Aerospace: Proper leveling is crucial for making engine components.

- Automotive: Chuck keys help in quick machine setups, boosting productivity.

In one case, a manufacturing plant improved its output by 25% after training workers on the correct use of chuck keys. This shows how small changes can make a big difference!

What are the real-world impacts of precision leveling and chuck keys?

Proper usage of chuck keys can reduce errors and speed up production. In fact, when machines are accurately leveled, they perform better, leading to fewer mistakes.

Conclusion

In conclusion, using a lathe precision leveling tool helps you achieve accurate results in your metalwork. A key for your lathe chuck ensures secure holding of materials. By mastering these skills, you improve your craftsmanship. We encourage you to practice regularly and explore more resources to deepen your understanding. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathe, And Chuck Key:Sure! A lathe is a machine that shapes metal. To keep it working well, you need to level it. Leveling means making sure it is flat and straight. A chuck key is a tool we use to tighten or loosen the parts that hold the metal. This way, the metal stays secure while we work on it.

Sure! Please tell me the question you want me to answer.

What Techniques Can Be Used To Achieve Precise Leveling Of A Metal Lathe For Optimal Machining Performance?To level a metal lathe, you can use wedges or shims to adjust its height. First, check the level with a bubble level tool. Next, place the wedges or shims under the legs until it’s even. You can also measure from the floor to different points on the lathe to ensure they match. After leveling, tighten all the screws to keep it stable.

How Does The Accuracy Of A Chuck Key Impact The Overall Precision Of Machining Operations On A Metal Lathe?The chuck key helps hold the tool on the metal lathe tightly. If the chuck key is not accurate, the tool can move. This movement makes our work less precise and can ruin our projects. So, we need an accurate chuck key to make sure everything stays in place and works well. This way, we can create smoother and better shapes in our metal work.

What Are The Common Signs Of A Poorly Leveled Lathe, And How Can They Affect The Quality Of The Workpiece?If a lathe isn’t leveled right, you might see some problems. The workpiece could look wavy or uneven. You might notice extra vibration or loud noises while it runs. These issues can make your workpiece weaker or not fit well. It’s important to keep the lathe balanced for the best results!

Which Types Of Chuck Keys Are Most Suitable For Different Sizes Of Metal Lathe Chucks, And Why Is This Important?There are different types of chuck keys for metal lathes. A small chuck key works for tiny chucks, while a big one suits larger chucks. Choosing the right key is important because it helps you tighten or loosen the chuck better. If the key doesn’t fit well, it can be hard to use or even break. So, using the right size helps keep everything safe and working well.

What Regular Maintenance Practices Can Be Implemented To Ensure The Longevity And Precision Of A Metal Lathe And Its Chuck Key?To keep your metal lathe and chuck key in good shape, clean them regularly. You should wipe off dust and chips after each use. Check the chuck key for any damage and replace it if it’s broken. Also, apply oil to moving parts to keep everything smooth. Finally, make sure everything is tight and in the right place before you start working!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathe, And Chuck Key:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal. To keep it working well, you need to level it. Leveling means making sure it is flat and straight. A chuck key is a tool we use to tighten or loosen the parts that hold the metal. This way, the metal stays secure while we work on it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Achieve Precise Leveling Of A Metal Lathe For Optimal Machining Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you can use wedges or shims to adjust its height. First, check the level with a bubble level tool. Next, place the wedges or shims under the legs until it’s even. You can also measure from the floor to different points on the lathe to ensure they match. After leveling, tighten all the screws to keep it stable.”}},{“@type”: “Question”,”name”: “How Does The Accuracy Of A Chuck Key Impact The Overall Precision Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The chuck key helps hold the tool on the metal lathe tightly. If the chuck key is not accurate, the tool can move. This movement makes our work less precise and can ruin our projects. So, we need an accurate chuck key to make sure everything stays in place and works well. This way, we can create smoother and better shapes in our metal work.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of A Poorly Leveled Lathe, And How Can They Affect The Quality Of The Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe isn’t leveled right, you might see some problems. The workpiece could look wavy or uneven. You might notice extra vibration or loud noises while it runs. These issues can make your workpiece weaker or not fit well. It’s important to keep the lathe balanced for the best results!”}},{“@type”: “Question”,”name”: “Which Types Of Chuck Keys Are Most Suitable For Different Sizes Of Metal Lathe Chucks, And Why Is This Important?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are different types of chuck keys for metal lathes. A small chuck key works for tiny chucks, while a big one suits larger chucks. Choosing the right key is important because it helps you tighten or loosen the chuck better. If the key doesn’t fit well, it can be hard to use or even break. So, using the right size helps keep everything safe and working well.”}},{“@type”: “Question”,”name”: “What Regular Maintenance Practices Can Be Implemented To Ensure The Longevity And Precision Of A Metal Lathe And Its Chuck Key?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe and chuck key in good shape, clean them regularly. You should wipe off dust and chips after each use. Check the chuck key for any damage and replace it if it’s broken. Also, apply oil to moving parts to keep everything smooth. Finally, make sure everything is tight and in the right place before you start working!”}}]}