Have you ever wondered how to make a metal lathe work perfectly? Imagine a machine that shapes metal with incredible accuracy. That’s where lathe precision leveling comes in. It’s the secret to getting the best performance from your metal lathe controller.

Many people might not realize how important leveling is. If a lathe is off balance, it can cause mistakes. These mistakes can ruin projects and waste materials. But with proper leveling techniques, you can avoid these problems.

Think about this: If you’re building a model car, every tiny detail matters. Just like that, precise leveling on a lathe ensures every cut and shape is right. Did you know that even a small tilt can affect the final product? It’s true!

In this article, we will explore how to level your lathe and why it’s crucial. You’ll see how the right tools can help you control your metal lathe like a pro. Get ready to dive into the world of lathe precision leveling!

Lathe Precision Leveling: Metal Lathe Controller Guide

Unlocking Precision with Lathe Leveling Control

Lathe precision leveling is crucial for metalworking projects. A well-leveled lathe ensures fine accuracy and better results in machining. Did you know that improper leveling can lead to poor part quality? A metal lathe controller can help you make quick adjustments, enhancing your work’s efficiency. This simple upgrade can save you time and improve your skills. With the right setup, anyone can achieve professional-quality work from their home workshop. Why not give it a try?Understanding Lathe Precision Leveling

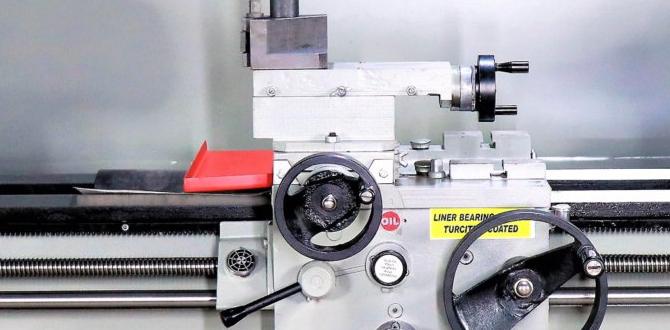

Importance of precision leveling in lathe operations. Common techniques for achieving precision leveling.Precision leveling is key for lathe operations. It ensures that the machine works smoothly and produces high-quality parts. Without proper leveling, you can face issues like vibrations and inaccuracies. This can lead to mistakes and wasted materials.

Common techniques for achieving precision leveling include:

- Using a level tool to check surfaces.

- Adjusting the lathe’s legs or pads.

- Checking for any bumps or uneven spots.

Why is precision important in lathe operations?

Precision leveling helps create straight and even cuts. It reduces wear and tear on the lathe, making it last longer.

How do I know my lathe is level?

Regularly check the machine using a level tool. Look out for any changes in precision over time.

In conclusion, keeping your lathe well-leveled is essential for success. It improves your work and saves time and effort.

Steps to Achieve Precision Leveling

Stepbystep guide to properly level a lathe. Tips for ensuring accuracy during the leveling process.Leveling a lathe is essential for smooth operation. Follow these steps for proper leveling:

- Check the floor for evenness. A flat surface is key.

- Place a level on the lathe bed. Adjust feet as needed.

- Recheck the level from different angles.

- Ensure alignment with the tailstock and chuck.

For accuracy, take your time. Double-check each step. Small errors can lead to big issues. Remember, a well-leveled lathe offers better results.

Why is precision leveling important?

Precision leveling helps avoid mistakes in machining, ensuring smooth operation and accurate parts.

Tips for Better Leveling:

- Use a high-quality level.

- Check for vibrations in the area.

- Keep tools nearby for quick adjustments.

Common Problems and Solutions in Lathe Leveling

Identifying issues caused by improper leveling. Solutions and adjustments to rectify leveling problems.Improper leveling of a lathe can cause serious problems. You might notice uneven cuts or strange noises. These issues can lead to poor quality work. To fix these, start by checking the lathe’s level with a bubble level. Adjust the feet if needed. Here are some common issues and solutions:

- Uneven cuts: Adjust the leveling feet for balance.

- Excessive vibrations: Check the foundation for stability.

- Noisy operation: Ensure all components are tight and secure.

Regular checks keep your lathe working well and make your projects easier!

How do I know if my lathe is level?

Check your lathe with a bubble level. If the bubble is off-center, your lathe is not level.

How to Choose the Right Metal Lathe Controller

Factors to consider when selecting a controller. Comparison of top metal lathe controllers in the market.Picking the right metal lathe controller is vital for your projects. Start by considering control precision, ease of use, and compatibility with your lathe. Look for features like speed settings and display quality. Research the top brands to see how they perform. Popular choices often offer user-friendly designs and solid support. Comparing features helps in making a smart choice.

- Control Precision

- Ease of Use

- Compatibility

- Speed Settings

- Support and Warranty

What to look for in a metal lathe controller?

Look for ease of operation, precision control, and good customer support. These features help ensure you get the most out of your lathe, making your work easier and more efficient.

Integrating Precision Leveling with Metal Lathe Controllers

How controller settings can affect precision leveling. Best practices for synchronizing leveling and controller use.Getting the controller settings right is key for precision leveling. Too loose, and your lathe might wobble like a toddler on roller skates! Best practices involve regularly checking settings, ensuring everything is snug yet flexible. Syncing the controller and leveling can turn your machine from “meh” to “wow!” Check the table below for easy tips:

| Best Practices | Description |

|---|---|

| Calibration | Always calibrate before starting. |

| Regular Maintenance | Keep parts clean and sharp. |

| Monitor Settings | Check your controller settings often. |

| Leveling Checks | Re-level after a heavy cut. |

Remember, a well-set controller can transform your metal lathe experience. Happy turning!

Advanced Techniques for Enhanced Lathe Performance

Incorporating CNC technology in lathe operations. Future trends in lathe precision and control technology.Modern lathes are stepping into the future with CNC technology, making them smarter and faster. Imagine a robot doing your lathe work—sounds fun, right? With CNC, your lathe can accurately cut metal shapes while you sip your coffee. The latest trends focus on precision and control, ensuring every piece is perfect. In fact, experts say CNC can improve production speed by up to 40%!

| Feature | Benefits |

|---|---|

| Increased Precision | Better quality products |

| Automated Operations | Less manual work |

| Data Tracking | Improved control |

So, embrace the lathe revolution! With enhanced control, your projects will not only shine but may also turn heads. Who knew metalworking could be this exciting?

Conclusion

In conclusion, using a lathe precision leveling metal lathe controller ensures your machine operates accurately. Proper leveling helps you create better parts and enjoy smoother operation. You can improve your skills by trying out different leveling techniques. For more information, consider reading guides or watching videos on lathe setup. Happy machining and keep exploring!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Controllers:Sure! Here are five questions we can ask about lathe precision leveling and metal lathe controllers: 1. **Why is leveling a lathe important?** Leveling a lathe helps it work correctly. If it’s not level, it can cut unevenly and make mistakes. 2. **What does a metal lathe controller do?** A metal lathe controller helps you control the machine. It can change the speed and direction of the cutting tools. 3. **How can you tell if a lathe is level?** You can use a bubble level tool. If the bubble is in the middle, it’s level. 4. **What tools do you need for leveling?** You just need a bubble level and maybe some shims to adjust the height. 5. **Can leveling a lathe improve my work?** Yes! A well-leveled lathe makes better cuts. This means your projects will look nicer and be more precise.

Sure! Please provide the question you would like me to answer.

What Are The Key Factors To Consider When Leveling A Metal Lathe For Optimal Precision Machining?When you level a metal lathe, you want to make sure it’s flat and even. First, check that the lathe is on a sturdy surface that won’t move. Use a level tool to see if it’s straight from side to side and front to back. Next, adjust the feet of the lathe if it’s not level. Lastly, make sure the tools are tight and ready to work smoothly for the best results.

How Can A Digital Lathe Controller Improve The Accuracy And Repeatability Of Machining Operations On A Metal Lathe?A digital lathe controller helps you make precise cuts on a metal lathe. It uses special computer programs to guide the machine. This means you can get the same results every time you use it. When you change parts, the controller remembers the settings, so everything stays accurate. Overall, it makes your work safer and faster!

What Tools And Techniques Are Commonly Used To Check And Achieve Precision Leveling On A Lathe?To check if a lathe is level, we can use a leveling tool called a spirit level. This tool has a bubble that shows if the lathe is straight. You can also use a machinist’s square to make sure things are at the right angles. Another way is to check measurements with a caliper to make sure everything is the same distance apart. Finally, making small adjustments can help get everything just right.

How Does The Alignment Of A Lathe Impact The Quality Of The Finished Workpiece, Particularly In Precision Applications?The alignment of a lathe is very important to make good parts. When the lathe is straight, it can cut cleanly. If it is crooked, the cuts can be rough or uneven. This matters a lot when we need very precise pieces, like parts for machines. Good alignment helps you create smooth and accurate workpieces that fit together well.

What Are The Differences Between Manual And Cnc Lathe Controllers In Terms Of Ensuring Precise Leveling And Machining?Manual lathes need you to move the tools by hand. You have to be very careful to level things right. CNC lathes, or Computer Numerical Control lathes, use a computer to control the tools. This makes it easier to get things just right, and you can repeat the same cuts perfectly every time. So, CNC lathes usually do a better job at making precise shapes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Controllers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we can ask about lathe precision leveling and metal lathe controllers: 1. **Why is leveling a lathe important?** Leveling a lathe helps it work correctly. If it’s not level, it can cut unevenly and make mistakes. 2. **What does a metal lathe controller do?** A metal lathe controller helps you control the machine. It can change the speed and direction of the cutting tools. 3. **How can you tell if a lathe is level?** You can use a bubble level tool. If the bubble is in the middle, it’s level. 4. **What tools do you need for leveling?** You just need a bubble level and maybe some shims to adjust the height. 5. **Can leveling a lathe improve my work?** Yes! A well-leveled lathe makes better cuts. This means your projects will look nicer and be more precise.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Leveling A Metal Lathe For Optimal Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you level a metal lathe, you want to make sure it’s flat and even. First, check that the lathe is on a sturdy surface that won’t move. Use a level tool to see if it’s straight from side to side and front to back. Next, adjust the feet of the lathe if it’s not level. Lastly, make sure the tools are tight and ready to work smoothly for the best results.”}},{“@type”: “Question”,”name”: “How Can A Digital Lathe Controller Improve The Accuracy And Repeatability Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital lathe controller helps you make precise cuts on a metal lathe. It uses special computer programs to guide the machine. This means you can get the same results every time you use it. When you change parts, the controller remembers the settings, so everything stays accurate. Overall, it makes your work safer and faster!”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Commonly Used To Check And Achieve Precision Leveling On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a lathe is level, we can use a leveling tool called a spirit level. This tool has a bubble that shows if the lathe is straight. You can also use a machinist’s square to make sure things are at the right angles. Another way is to check measurements with a caliper to make sure everything is the same distance apart. Finally, making small adjustments can help get everything just right.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of A Lathe Impact The Quality Of The Finished Workpiece, Particularly In Precision Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The alignment of a lathe is very important to make good parts. When the lathe is straight, it can cut cleanly. If it is crooked, the cuts can be rough or uneven. This matters a lot when we need very precise pieces, like parts for machines. Good alignment helps you create smooth and accurate workpieces that fit together well.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Manual And Cnc Lathe Controllers In Terms Of Ensuring Precise Leveling And Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes need you to move the tools by hand. You have to be very careful to level things right. CNC lathes, or Computer Numerical Control lathes, use a computer to control the tools. This makes it easier to get things just right, and you can repeat the same cuts perfectly every time. So, CNC lathes usually do a better job at making precise shapes.”}}]}