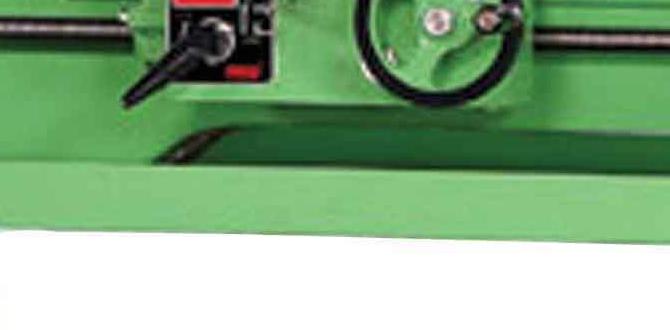

Have you ever wondered how metal lathes achieve such precision? Imagine a machine that can create perfectly shaped metal pieces. That’s where lathe precision leveling comes into play.

When using a metal lathe, every tiny shift matters. Even the slightest tilt can ruin a job. This is why leveling is so important. Properly leveling your lathe ensures accuracy, making your work easier and more fun.

But what about the cross slide? It’s a key part of the lathe that helps you move the cutting tool smoothly. A well-leveled cross slide will let you make clean cuts every time. Isn’t it amazing how small adjustments can lead to big results?

In this article, we’ll dive into the world of lathe precision leveling. We’ll explore tips and tricks to help you get the most out of your metal lathe. Ready to unlock the secrets of perfect machining? Let’s get started!

Achieving Accuracy: Lathe Precision Leveling Metal Lathe Cross Slide

Lathe Precision Leveling for Metal Lathes

Lathe precision leveling is key for metal lathes. It helps keep your machine straight and accurate. Imagine working on a project, but your lathe misses the mark. Frustrating, right? Properly leveling the cross slide makes your cuts precise and smooth. Did you know that even a tiny misadjustment can lead to big mistakes in your work? By learning about leveling techniques, you can enhance your skills and create amazing projects without stress!Understanding Lathe Precision

Definition of lathe precision and its importance in machining.. Key factors influencing precision in metal lathes..Precision in lathes means how accurately they cut and shape metal. This accuracy is vital for making parts fit together perfectly. If a part is even a little off, it might not work as intended. Factors that affect precision include:

- Correct setup and calibration

- Sharp cutting tools

- Stable workpieces

- Well-maintained machines

High precision leads to better quality and less waste in machining. This way, products last longer and perform better.

Why is lathe precision important?

Precision affects the quality and performance of parts. It helps ensure that everything fits as it should.The Role of Leveling in Metal Lathes

Explanation of how proper leveling affects lathe performance.. Common leveling techniques used in the industry..Leveling a metal lathe is like putting on your shoes—they have to fit just right! If the lathe isn’t level, it can cause trouble, making parts uneven. This means your projects might look more like art gone wrong instead of precision pieces. Simple techniques, like using a spirit level or adjusting the feet of the lathe, can help. Here’s a little table to show some common methods:

| Leveling Technique | Description |

|---|---|

| Spirit Level | Basic tool to check if the lathe is level. |

| Shim Blocks | Used to adjust the height of the lathe’s feet for fine-tuning. |

| T-Square | A trusty tool to ensure everything lines up straight. |

Using these methods can keep your lathe spinning smoothly. Remember, a happy lathe is a productive lathe!

Step-by-Step Guide to Leveling Your Metal Lathe

Tools and equipment needed for leveling a lathe.. Detailed procedure for leveling the lathe effectively..Leveling your metal lathe is essential for smooth operation. To start, gather your tools: a bubble level, adjustable wrenches, and shim stock. You might also need a strong cup of coffee for motivation!

| Tools | Purpose |

|---|---|

| Bubble Level | Check the lathe’s level |

| Adjustable Wrenches | Loosen or tighten feet |

| Shim Stock | Fill gaps if needed |

First, place the bubble level on the bed of the lathe. Adjust the feet until the bubble sits perfectly centered. If you find a gap, use shim stock to fill it up. Lastly, double-check with the level. If it’s still off, you may need to adjust your coffee supply!

Common Mistakes to Avoid When Leveling a Lathe

Typical errors made during the leveling process.. Strategies to identify and correct these mistakes..Leveling a lathe can seem easy, but it’s a bit like baking a cake—you can easily forget an ingredient. One common mistake is skipping the use of a level tool; this can lead to a wobbly lathe and uneven cuts. Another blunder is assuming the floor is flat; sometimes, it’s more like a rollercoaster ride. To spot errors, regularly check your setups and adjust accordingly. Here’s a quick cheat sheet:

| Error | Solution |

|---|---|

| Not using a level | Always use a bubble level. |

| Ignoring the floor | Check for levelness beneath the lathe. |

| Incorrect adjustments | Calibrate with precision tools. |

Taking these steps helps avoid headaches—both in your head and in your projects!

Maintenance Tips for Maintaining Lathe Precision

Routine checks and adjustments for longterm precision.. Best practices for maintaining the cross slide mechanism..Keeping your metal lathe in top shape is like feeding a pet: regular care goes a long way! First, do routine checks. Look for loose parts, signs of wear, and clean the lathe regularly. Adjust your settings to keep everything snug. For the cross slide mechanism, smooth movement is key! Lubricate it often and avoid dirt. A happy lathe means precise work and fewer snack breaks—unless it’s snack o’clock, of course!

| Maintenance Tip | Description |

|---|---|

| Routine Checks | Inspect for loose screws and clean regularly. |

| Adjustments | Tweak parts for snug fit to avoid wobbling. |

| Cross Slide Care | Lubricate often for smooth movement. |

Advanced Techniques for Enhanced Leveling Precision

Innovative methods and tools for achieving higher precision.. Case studies of successful precision leveling in metal lathes..New methods can improve leveling precision for lathes. Tools like digital levels and angle finders help users check their setup. These devices give accurate readings, making work easier. Case studies show how different shops achieved great results. They reported better cuts and fewer mistakes. This saved time and materials. Using the right tools can really boost quality, showing that precision matters.

What tools improve lathe leveling precision?

Tools like digital levels and angle finders increase accuracy and help achieve precise leveling.

Innovative Techniques:

- Using laser levels for straightness

- Employing precision measuring devices

- Regularly calibrating machines

Conclusion

In summary, leveling your metal lathe’s cross slide is crucial for precision work. A well-leveled lathe improves accuracy and quality in your projects. You should check and adjust your lathe regularly for the best results. Try experimenting with leveling techniques, and explore more resources on metal lathes to enhance your skills further! Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically Concerning Metal Lathe Cross Slides:To make your metal lathe work well, we need to level it carefully. This means checking that the machine is flat and not tilted. If the cross slide is not level, it can cause mistakes in cutting. You can use a level tool to help with this. Always double-check your work to make sure everything is set right!

Sure! Just ask your question, and I’ll give you a simple answer!

What Are The Key Techniques For Achieving Precision Leveling Of A Metal Lathe Cross Slide?To level the cross slide on a metal lathe, you need to follow a few steps. First, use a level tool to check if it’s even. Next, adjust the feet of the lathe until it lines up perfectly. You may need to tighten screws to hold everything in place. Finally, double-check your work to make sure it’s still level.

How Can Inconsistencies In A Lathe’S Cross Slide Affect The Accuracy Of Machining Operations?If a lathe’s cross slide is not steady, it can cause problems. When you move it, it might not go exactly where you want. This can make your cuts uneven or crooked. If you want your work to be perfect, we need the cross slide to be just right. Otherwise, our pieces won’t fit together as they should.

What Tools And Instruments Are Recommended For Checking And Adjusting The Level Of A Metal Lathe Cross Slide?To check and adjust the level of a metal lathe cross slide, you can use a level. A spirit level is a tool with a small bubble in a liquid-filled tube. You place it on the cross slide to see if it’s flat. A dial gauge can help you measure tiny changes. These tools ensure your lathe works well and makes good parts.

How Often Should The Leveling Of A Metal Lathe Cross Slide Be Checked And Readjusted During Regular Maintenance?You should check the level of your metal lathe cross slide every few weeks. If you use it a lot, check it more often. Making sure it’s level helps your work be more accurate. If you notice any problems, adjust it right away. This keeps everything running smoothly!

What Are The Common Signs Indicating That A Metal Lathe Cross Slide Is Not Properly Leveled?If your metal lathe cross slide is not level, you might see uneven cuts on your workpiece. The tool might dig too deep in some spots and barely touch in others. You could also notice that it’s hard to move the slide smoothly. If you check, the slide might wobble or feel loose. These signs mean you need to adjust it for better work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically Concerning Metal Lathe Cross Slides:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your metal lathe work well, we need to level it carefully. This means checking that the machine is flat and not tilted. If the cross slide is not level, it can cause mistakes in cutting. You can use a level tool to help with this. Always double-check your work to make sure everything is set right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a simple answer!”}},{“@type”: “Question”,”name”: “What Are The Key Techniques For Achieving Precision Leveling Of A Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level the cross slide on a metal lathe, you need to follow a few steps. First, use a level tool to check if it’s even. Next, adjust the feet of the lathe until it lines up perfectly. You may need to tighten screws to hold everything in place. Finally, double-check your work to make sure it’s still level.”}},{“@type”: “Question”,”name”: “How Can Inconsistencies In A Lathe’S Cross Slide Affect The Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe’s cross slide is not steady, it can cause problems. When you move it, it might not go exactly where you want. This can make your cuts uneven or crooked. If you want your work to be perfect, we need the cross slide to be just right. Otherwise, our pieces won’t fit together as they should.”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Recommended For Checking And Adjusting The Level Of A Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the level of a metal lathe cross slide, you can use a level. A spirit level is a tool with a small bubble in a liquid-filled tube. You place it on the cross slide to see if it’s flat. A dial gauge can help you measure tiny changes. These tools ensure your lathe works well and makes good parts.”}},{“@type”: “Question”,”name”: “How Often Should The Leveling Of A Metal Lathe Cross Slide Be Checked And Readjusted During Regular Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the level of your metal lathe cross slide every few weeks. If you use it a lot, check it more often. Making sure it’s level helps your work be more accurate. If you notice any problems, adjust it right away. This keeps everything running smoothly!”}},{“@type”: “Question”,”name”: “What Are The Common Signs Indicating That A Metal Lathe Cross Slide Is Not Properly Leveled?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe cross slide is not level, you might see uneven cuts on your workpiece. The tool might dig too deep in some spots and barely touch in others. You could also notice that it’s hard to move the slide smoothly. If you check, the slide might wobble or feel loose. These signs mean you need to adjust it for better work.”}}]}