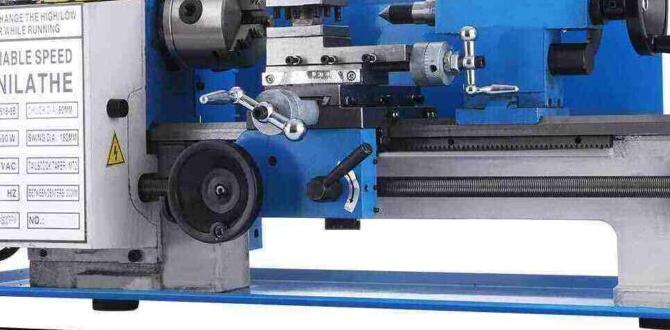

Every craftsman knows the importance of precision. Imagine trying to shape a piece of metal without it being perfectly level. It would be like trying to build a house on a shaky foundation. That’s where lathe precision leveling comes in. This crucial step ensures your metal lathe operates smoothly and accurately.

Have you ever watched a lathe in action? The way it transforms metal is fascinating. Adding a Digital Readout (DRO) can make it even better. A DRO shows you exactly where the tool is, which helps create perfect cuts. This combination of precise leveling and the smart technology of a DRO can elevate your work to a whole new level.

But why stop there? Leveling your lathe not only improves accuracy. It also extends the life of your equipment. A well-leveled lathe requires less energy and reduces wear on its parts. This means fewer repairs and more time crafting amazing items.

So, are you ready to dive into the world of lathe precision leveling? Understanding this process is the first step toward creating masterful projects. Let’s explore how these elements work together to enhance your metalworking journey!

Lathe Precision Leveling: Metal Lathe Dro Guide

Lathe Precision Leveling for Metal Lathe DRO

Lathe precision leveling is essential for accurate machining. It ensures the lathe is perfectly positioned, minimizing errors. A Digital Readout (DRO) can help monitor and adjust levels quickly, making your projects more efficient. Imagine crafting parts that fit perfectly every time! Did you know that even a slight tilt can impact the quality of your work? Understanding how to level your metal lathe can drastically improve your results and make your crafting journey enjoyable.Essential Tools for Precision Leveling

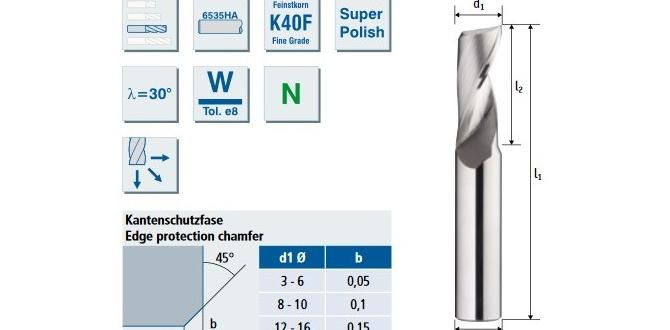

List of tools required for effective leveling (e.g., levels, shims, indicators).. Explanation of how each tool contributes to the leveling process..To level your lathe like a pro, you need some trusty tools. First, a spirit level shows if your lathe is flat, so it’s not wobbling like a jelly on a plate. Next, shims help fill in those pesky gaps, making everything fit snugly. Lastly, indicators give precise readings, ensuring your setup is spot on. Together, these tools make leveling a breeze. Remember, a well-leveled lathe keeps the fun in your metalwork!

| Tool | Purpose |

|---|---|

| Spirit Level | Checks if your lathe is level |

| Shims | Fill gaps for a snug fit |

| Indicators | Provide precise measurements |

Steps for Proper Lathe Leveling

Detailed stepbystep instructions for leveling a lathe.. Tips for identifying and correcting common leveling issues..Leveling a lathe is crucial for accurate work. Follow these simple steps for proper leveling:

- Start by placing the lathe on a solid base.

- Check the level with a precision level. Adjust the feet until it is level.

- Measure from the bed to the floor at multiple points. All measurements should be the same.

- If the lathe rocks, shim under the feet for stability.

- Finally, recheck with the level after making adjustments.

Common issues include uneven feet or an unstable surface. Always ensure the ground is strong. If your lathe vibrates, check for loose parts and tighten them.

How do you know if the lathe is level?

You can check this by using a precision level tool on different parts of the lathe.Tips for level checking:

- Look for consistent readings on the level.

- Test in various locations across the bed.

The Role of Digital Readouts (DRO) in Precision Leveling

Explanation of how DRO systems enhance precision in lathe operations.. Benefits of integrating DRO with precision leveling practices..Digital readouts (DRO) are like superheroes for metal lathes! They help to accurately show measurements during lathe operations. With DRO systems, you can level your lathe with precision, which makes cutting metal easier and less stressful. You won’t be guessing where to cut! Integrating DRO into your routine saves time and reduces mistakes. It’s like having a wise old owl guiding your every move! Plus, your projects will look sharper, and you’ll feel like a pro.

| Benefits of DRO | Description |

|---|---|

| Enhanced Accuracy | DRO provides real-time measurements, so you cut perfectly! |

| Saves Time | No more fiddling with guesswork means you finish faster! |

| Reduces Mistakes | With clear readings, errors become a rare event! |

Incorporating DRO into your precision leveling practices is a smart move! Remember, it turns your lathe into a precision machine rather than a guesswork tool.

Maintaining Your Lathe for Long-term Precision

Guidelines for regular maintenance that support ongoing precision.. Importance of calibration and leveling checks in maintenance routines..Keeping your lathe in good shape is important for smooth and precise work. Regular maintenance helps maintain quality. Here are a few guidelines to follow:

- Check for loose parts and tighten them.

- Clean the machine regularly to avoid dirt buildup.

- Lubricate moving parts to keep them running smoothly.

- Inspect the DRO and leveling regularly for accuracy.

Calibration and leveling checks are essential. A well-leveled lathe improves accuracy. When the lathe is aligned properly, it reduces mistakes. Regular maintenance leads to long-term precision, making your projects easier.

Why is calibration and leveling important?

Calibration and leveling keep your lathe precise and reduce errors. Regular checks ensure your machine works well, which is key for high-quality projects.

Case Studies: Successful Precision Leveling in Action

Example scenarios where precision leveling significantly improved machining results.. Analysis of the methods used and outcomes achieved..Many workshops saw big results with precision leveling in their metal lathes. Here are some scenarios of success:

- A local machine shop improved part accuracy by 25% after leveling their lathe.

- Another firm reduced tool wear by 30% with careful setup and checks.

- A university lab had students complete projects faster due to better precision.

These cases show that precision leveling can greatly enhance machining quality. Using precise methods helped each team reach their goals while minimizing errors.

Why is precision leveling important?

Precision leveling is key because it ensures machines run smoothly and produce better parts. This means fewer mistakes and more success for everyone involved.

Conclusion

In summary, precision leveling is crucial for using a metal lathe effectively. A Digital Readout (DRO) helps you measure accurately. This makes your work more precise and efficient. To improve your skills, consider practicing leveling techniques today. Explore more resources online to deepen your understanding. With the right tools and knowledge, you can achieve great results in your metalworking projects!FAQs

Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathes, And Dro (Digital Readout) Systems:Lathe precision leveling is important because it makes sure the machine works well. A metal lathe shapes metal into different parts. Adding a Digital Readout (DRO) helps you see exact measurements while working. This tool makes it easier to be accurate when cutting or shaping. With good leveling and DRO, you’ll make better parts!

Sure! Please provide the question you want me to answer.

What Methods Can Be Used To Achieve Precise Leveling Of A Metal Lathe Before Operation?To level a metal lathe, you can use a few easy methods. First, check the floor under the lathe. Make sure it’s flat and strong. Next, you can use a level tool. Place it on the bed of the lathe to see if it’s straight. Lastly, adjust the legs of the lathe until it is perfectly level. This will help your lathe work better!

How Does The Precision Of Leveling Affect The Accuracy Of Machining Operations On A Metal Lathe?When we use a metal lathe, we want it to be straight. If the lathe isn’t level, it can wobble. This wobbling makes our cuts uneven. By leveling the lathe well, we can make better and more precise parts. So, good leveling helps us make things that fit together perfectly.

What Are The Advantages Of Using A Digital Readout (Dro) System In Conjunction With A Leveled Metal Lathe?Using a Digital Readout (DRO) system with a leveled metal lathe helps you in many ways. First, it shows exact measurements, so you can make cuts more accurately. Second, it saves time because you don’t have to keep measuring with a ruler. Lastly, it makes your work easier, letting you focus on creating cool stuff without mistakes.

What Common Challenges Might Arise When Leveling A Metal Lathe In A Workshop Setting, And How Can They Be Addressed?When leveling a metal lathe, you might face a few challenges. The floor may not be completely flat, making it hard to get the lathe straight. You can fix this by using shims or adjustable feet. Another issue could be making sure everything is tight and secure during leveling. Always check connections and bolts to prevent wobbles while working.

How Often Should A Metal Lathe Be Re-Leveled, And What Indicators Suggest It May Need Adjustment?You should check if a metal lathe needs re-leveling about every few months. If you notice that your projects aren’t coming out straight, that might mean it needs adjustment. Other signs include unusual vibrations or if parts do not fit together well. Always make sure to keep it level, so your work stays accurate!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathes, And Dro (Digital Readout) Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe precision leveling is important because it makes sure the machine works well. A metal lathe shapes metal into different parts. Adding a Digital Readout (DRO) helps you see exact measurements while working. This tool makes it easier to be accurate when cutting or shaping. With good leveling and DRO, you’ll make better parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Methods Can Be Used To Achieve Precise Leveling Of A Metal Lathe Before Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you can use a few easy methods. First, check the floor under the lathe. Make sure it’s flat and strong. Next, you can use a level tool. Place it on the bed of the lathe to see if it’s straight. Lastly, adjust the legs of the lathe until it is perfectly level. This will help your lathe work better!”}},{“@type”: “Question”,”name”: “How Does The Precision Of Leveling Affect The Accuracy Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a metal lathe, we want it to be straight. If the lathe isn’t level, it can wobble. This wobbling makes our cuts uneven. By leveling the lathe well, we can make better and more precise parts. So, good leveling helps us make things that fit together perfectly.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Digital Readout (Dro) System In Conjunction With A Leveled Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a Digital Readout (DRO) system with a leveled metal lathe helps you in many ways. First, it shows exact measurements, so you can make cuts more accurately. Second, it saves time because you don’t have to keep measuring with a ruler. Lastly, it makes your work easier, letting you focus on creating cool stuff without mistakes.”}},{“@type”: “Question”,”name”: “What Common Challenges Might Arise When Leveling A Metal Lathe In A Workshop Setting, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When leveling a metal lathe, you might face a few challenges. The floor may not be completely flat, making it hard to get the lathe straight. You can fix this by using shims or adjustable feet. Another issue could be making sure everything is tight and secure during leveling. Always check connections and bolts to prevent wobbles while working.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Re-Leveled, And What Indicators Suggest It May Need Adjustment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check if a metal lathe needs re-leveling about every few months. If you notice that your projects aren’t coming out straight, that might mean it needs adjustment. Other signs include unusual vibrations or if parts do not fit together well. Always make sure to keep it level, so your work stays accurate!”}}]}