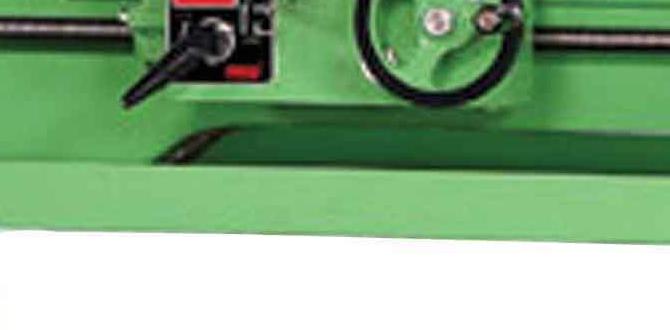

Have you ever watched a metal lathe at work? It spins and shapes metal with incredible precision. But did you know that proper setup is key for accurate results? One important aspect is lathe precision leveling. It helps your machine work perfectly.

Imagine trying to ride a bike on a bumpy road. It’s tough, right? A lathe needs a stable base to function well, too. That’s where leveling comes in. Without it, your projects could turn out all wrong!

Also, let’s talk about safety. A well-leveled lathe not only performs better, but it also keeps you safe. Have you ever stepped on a foot brake? It stops things quickly, right? Just like that brake, proper setup halts mistakes before they happen.

In this article, we will explore how to level your metal lathe for the best results. Get ready to learn some neat tips and tricks that make metalworking easier and safer!

Lathe Precision Leveling: Metal Lathe Foot Brake Tips

Lathe Precision Leveling: Metal Lathe Foot Brake

Precision leveling is crucial for metal lathes. A well-leveled lathe ensures smooth operation and accuracy in your projects. Have you ever noticed how uneven surfaces can cause errors in your work? A sturdy foot brake adds safety and control during use. This tool allows you to stop the machine quickly, reducing accidents. By focusing on precision leveling and effective braking, you enhance your metalworking experience and achieve better results every time.Understanding Lathe Precision

Definition of precision in machining. Importance of precision for metal lathes.Precision in machining means making parts with great accuracy. For metal lathes, this is very important. If a part isn’t made well, it won’t fit or work as needed. Precision helps create high-quality products, which saves time and money. Here are some key points:

- Good precision leads to better performance.

- It reduces waste and faulty pieces.

- It ensures safety in machine use.

Being precise keeps projects on track and meets standards. This is essential for any machining job.

Why is precision important for metal lathes?

Precision ensures that parts fit together perfectly, increasing reliability and functionality.

The Basics of Leveling Your Lathe

Stepbystep guide to leveling a metal lathe. Tools required for accurate leveling.Leveling your lathe is like making sure a seesaw doesn’t tip over! First, gather your tools: a bubble level & a wrench. Start by placing your level on the lathe bed. Adjust the feet using your wrench until the bubble sits perfectly in the center. Don’t be shy to check twice; good things come to those who wait! Here’s a handy table to keep track:

| Tools Needed | Purpose |

|---|---|

| Bubble Level | Check flatness |

| Wrench | Adjust feet |

Keep repeating this process until your lathe is as straight as an arrow. Remember, a level lathe makes for happy metal!

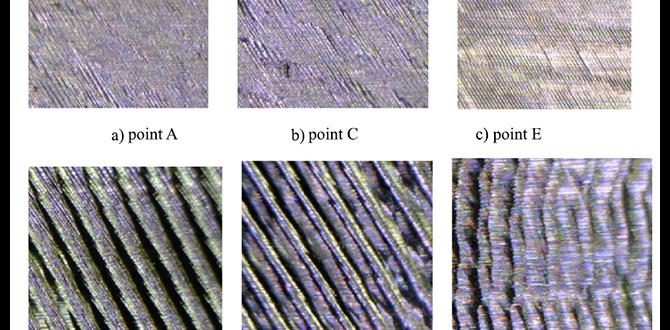

Impact of Leveling on Lathe Performance

Consequences of improper leveling. How leveling affects machining accuracy and finish.Leveling your lathe is super important! If it’s not level, you’re in for some trouble. You might see mistakes in your cuts, making it a real headache. The surface finish might look like a bad haircut—uneven and messy! In fact, improper leveling can lead to up to 50% more tool wear. Not good for your wallet! So, keep your lathe happy and level for fewer mistakes and a smoother ride!

| Consequence | Impact |

|---|---|

| Uneven Cuts | Poor accuracy |

| Bad Surface Finish | Extra sanding needed |

| Increased Tool Wear | More cash out of pocket |

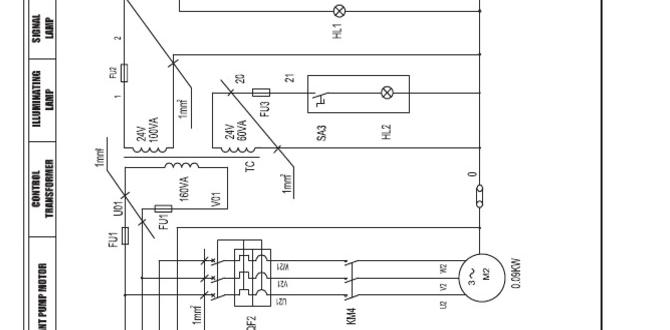

Foot Brake Systems in Metal Lathes

Functionality and advantages of a foot brake. Common types of foot brakes used in metal lathes.Foot brakes in metal lathes are like the superhero sidekick for your workspace. They let you stop the machine quickly, keeping you safe while you work. With just a tap, you can halt the lathe, making it very handy for precise cutting. Plus, they reduce wear on the machine since you don’t need to rely on the main power switch all the time.

Common types of foot brakes include the pedal-operated and the automatic ones. The pedal-operated brakes give you real control, while automatic brakes can stop the lathe without much fuss. Here’s a quick comparison:

| Brake Type | Functionality | Advantages |

|---|---|---|

| Pedal-Operated | Manual control with a foot pedal | High precision and control |

| Automatic | Stops automatically | User-friendly and quick |

With these brakes, you can work quicker and safer!

Installing a Foot Brake: A Practical Guide

Tools and materials needed for installation. Stepbystep installation process.Ready to install your foot brake? You’ll need a few tools and materials first. Gather a wrench, screws, and a measuring tape. Don’t forget safety gear! Now, let’s jump into the steps.

| Tools | Materials |

|---|---|

| Wrench | Screws |

| Measuring Tape | Foot Brake Kit |

| Screwdriver | Safety Gear |

First, clear your workspace. Next, measure where the foot brake will go. Use your wrench to attach the brake securely. Remember, this is not the time for a wobbly brake! Finally, test it out. Keep your toes safe and happy!

Maintenance Tips for Lathe Precision

Routine checks for lathe leveling. Foot brake maintenance best practices.Keeping a lathe in tip-top shape is easier than you think! Regular checks will help you maintain precision leveling. Start by checking the leveling every week; a wobbly machine isn’t fun. Treat the foot brake with some love, too. Make sure it operates smoothly. A squeaky brake can lead to unexpected dance moves—definitely not the kind you want while using a lathe! Here’s a handy checklist:

| Task | Frequency |

|---|---|

| Check Leveling | Weekly |

| Inspect Foot Brake | Monthly |

| Clean Lubrication Points | Every 3 Months |

Following these tips can help ensure your lathe runs smoothly. A happy lathe makes for a happy crafter!

Advanced Enhancements for Improved Lathe Precision

Upgrades for leveling systems. Foot brake modifications for enhanced safety and control.Upgrading leveling systems on a lathe can greatly improve its accuracy. A stable lathe means better cuts and fewer mistakes. Consider adding adjustable legs for perfect leveling. They help keep the machine steady, even on uneven floors.

Foot brake modifications also enhance safety and control. A reliable foot brake lets you stop the lathe quickly. This can protect you and the machine. Think about a larger brake pedal for easy access. This way, safety is always within reach.

What are some upgrades for lathe safety?

Upgrades include better leveling systems and modified foot brakes. These changes help increase stability and safety during use.

Key Upgrades:

- Adjustable legs for leveling

- Larger foot brake pedal for easy access

- Improved brake systems for quick stopping

Common Issues and Troubleshooting

Diagnosing leveling problems in metal lathes. Foot brake issues and solutions.Many people face problems with metal lathes. One common issue is leveling. If your lathe wobbles, check its feet. Make sure they are even on the ground. Another problem is with the foot brake. If it sticks or does not work, it can be dangerous. Here are some tips:

- Check for dirt or grease on the brake.

- Make sure the brake springs are not broken.

- Look for loose connections that might affect the brake.

Solving these issues can help your lathe work better and safer.

What are the common issues with metal lathe foot brakes?

Common foot brake issues include sticking, breaking springs, and loose connections. These problems can make the lathe hard to control and unsafe. Regular checks can help catch these issues early.

Comparative Analysis of Lathe Models

Key features to look for in precision lathes. Review of popular metal lathe models with leveling and braking capabilities.Choosing a precision lathe model can be tricky. Here are some key features to consider:

- Accuracy: Look for models with tight tolerances.

- Stability: A steady base helps in getting the best cuts.

- Foot Brake: Safety should always come first.

Some popular models include:

- Model A: Known for its precise leveling.

- Model B: Features a reliable foot brake.

- Model C: Great for both beginners and experts.

Finding the right lathe makes all the difference in your projects. Choose wisely!

What makes a good metal lathe?

A good metal lathe should have precision, stability, and a safe foot brake. These features help you work better and safer. Always check reviews to see what others like!

Conclusion

In conclusion, using a lathe with precision leveling is crucial for accurate work. A good foot brake enhances safety and control during operation. Remember to regularly check your lathe’s setup for the best results. You can explore more about lathe maintenance and safety tips to improve your skills. Happy machining, and stay safe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically For A Metal Lathe With A Focus On Foot Brake:When we talk about leveling a metal lathe, we want it to be just right. This helps the lathe work better and make precise parts. If the foot brake doesn’t work well, it can be unsafe. You should check the lathe’s level often. This keeps everything running smoothly and safely.

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Are The Key Steps Involved In Precision Leveling A Metal Lathe To Ensure Optimal Machining Accuracy?To precision level a metal lathe, first find a flat and strong surface for it to sit on. Next, use a level to check if the lathe is straight. If it’s not, adjust the feet of the lathe until it is level. After that, double-check the level to make sure it’s perfect. Finally, tighten everything up so it stays in place while you work.

How Does The Foot Brake Mechanism On A Metal Lathe Contribute To User Safety And Operational Efficiency?The foot brake on a metal lathe helps you stop the machine quickly. When you press it, the lathe slows down fast, which keeps you safe. This quick stop means you can change tools or materials without waiting long. It helps you work faster and keeps everything running smoothly.

What Tools And Techniques Can Be Used To Measure And Adjust The Level Of A Metal Lathe Accurately?To measure and adjust the level of a metal lathe, you can use a spirit level. This tool helps you see if the lathe is straight. You should also check with calipers, which measure distances very accurately. If the lathe is uneven, adjust the feet until it’s level. Finally, always double-check your work to make sure it’s right!

How Often Should A Metal Lathe Be Re-Leveled, And What Factors Can Impact Its Leveling Over Time?You should re-level a metal lathe at least once a month. Changes in weight, temperature, or humidity can affect its level. Moving the lathe or using it a lot can also cause it to shift. It’s good to check it whenever you notice any problems with your work. Keeping it level helps you make better parts!

What Are Some Common Issues That Can Arise From An Improperly Leveled Lathe, And How Can The Foot Brake Design Mitigate These Problems?If a lathe isn’t level, it can wobble and make bad cuts. This can lead to rough or uneven pieces. You might also see extra wear on parts, which can make the lathe break down faster. A good foot brake helps by stopping the lathe quickly, so you can fix problems before they get worse. It keeps you safe, too!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically For A Metal Lathe With A Focus On Foot Brake:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we talk about leveling a metal lathe, we want it to be just right. This helps the lathe work better and make precise parts. If the foot brake doesn’t work well, it can be unsafe. You should check the lathe’s level often. This keeps everything running smoothly and safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Precision Leveling A Metal Lathe To Ensure Optimal Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To precision level a metal lathe, first find a flat and strong surface for it to sit on. Next, use a level to check if the lathe is straight. If it’s not, adjust the feet of the lathe until it is level. After that, double-check the level to make sure it’s perfect. Finally, tighten everything up so it stays in place while you work.”}},{“@type”: “Question”,”name”: “How Does The Foot Brake Mechanism On A Metal Lathe Contribute To User Safety And Operational Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The foot brake on a metal lathe helps you stop the machine quickly. When you press it, the lathe slows down fast, which keeps you safe. This quick stop means you can change tools or materials without waiting long. It helps you work faster and keeps everything running smoothly.”}},{“@type”: “Question”,”name”: “What Tools And Techniques Can Be Used To Measure And Adjust The Level Of A Metal Lathe Accurately?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and adjust the level of a metal lathe, you can use a spirit level. This tool helps you see if the lathe is straight. You should also check with calipers, which measure distances very accurately. If the lathe is uneven, adjust the feet until it’s level. Finally, always double-check your work to make sure it’s right!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Re-Leveled, And What Factors Can Impact Its Leveling Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should re-level a metal lathe at least once a month. Changes in weight, temperature, or humidity can affect its level. Moving the lathe or using it a lot can also cause it to shift. It’s good to check it whenever you notice any problems with your work. Keeping it level helps you make better parts!”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise From An Improperly Leveled Lathe, And How Can The Foot Brake Design Mitigate These Problems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe isn’t level, it can wobble and make bad cuts. This can lead to rough or uneven pieces. You might also see extra wear on parts, which can make the lathe break down faster. A good foot brake helps by stopping the lathe quickly, so you can fix problems before they get worse. It keeps you safe, too!”}}]}