Have you ever wondered how a metal lathe works so precisely? Imagine making a part for a robot or even a toy car. It all starts with the right tools and setup.

One tool that is essential is the lathe. It shapes metal into different parts. But did you know that leveling your lathe is really important? If it’s not level, you might end up with mistakes!

Let’s think about a gear train. It’s like a team working together to get a job done. Each gear has a role. So, how does this help with your metal lathe?

By understanding lathe precision leveling, you can make perfect pieces every time. It’s like magic when everything is set just right. So, do you want to dive deeper into the world of lathes and gears? Let’s explore together!

Lathe Precision Leveling: Mastering Metal Lathe Gear Train

Lathe Precision Leveling and Gear Train Insights

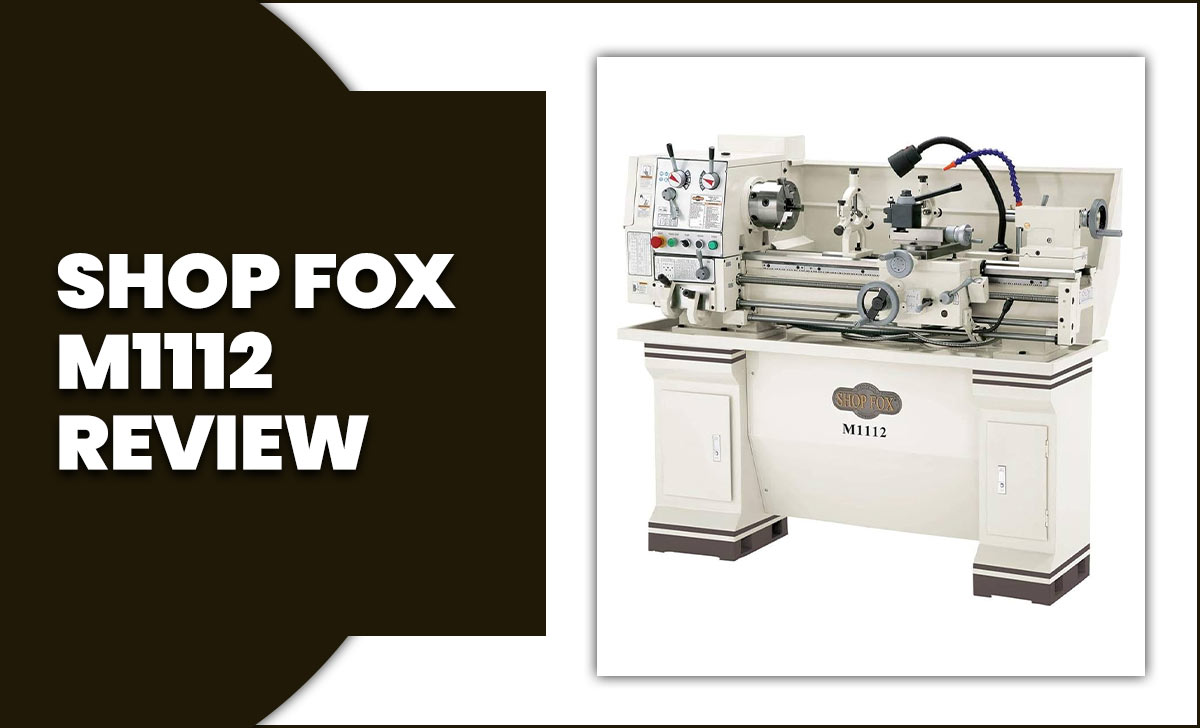

Lathe precision leveling is crucial for achieving accurate results in metalwork. A well-leveled lathe helps prevent errors during machining. Did you know that a small tilt can lead to major mistakes? The gear train in a lathe allows for smooth operation and precise adjustments. Understanding how these gears work together helps users optimize their machines. Proper leveling and gear training can significantly enhance a lathe’s performance, making every project more successful.Understanding Lathe Precision Leveling

Definition and importance of precision leveling in machining. Factors influencing precision in metal lathes.Precision leveling is like putting your lathe on a fancy diet. It ensures that the machine is perfectly balanced, allowing for smooth and accurate cutting. Think of it as a tightrope walker—one wrong move can lead to a tumble! Factors like the lathe’s surface, floor support, and how level the machine is can all influence results. If your lathe wobbles, your work might end up looking more like abstract art than precision machining!

| Factors Affecting Precision | Description |

|---|---|

| Lathe Surface | The surface must be even and stable to support accurate cutting. |

| Floor Support | Strong, level floors help keep the lathe steady. |

| Alignment | Proper alignment guarantees precise cuts and finishes. |

So, don’t overlook leveling! It’s critical for quality and saves time on adjustments. Plus, it keeps your metal lathe happy—because a happy lathe means happy workers!

The Role of Precision in Lathe Operation

Impact of precision on machining accuracy and final product quality. Consequences of improper leveling on lathe performance.Precision is key in lathe operation. It affects machining accuracy and the quality of the final product. A precise lathe can create parts that fit perfectly. If the lathe is not leveled right, it can lead to many problems.

- Parts may be too big or small.

- It can cause wear and damage to the machine.

- Inaccurate cuts can waste materials.

- Improper performance can frustrate users.

Precision matters. Attention to leveling keeps everything on track!

How does precision affect machining?

Precision affects machining by ensuring that parts are made to required sizes. If a lathe isn’t precise, the end product may not work properly.

Consequences of improper leveling:

- Poor fit and finish of parts.

- Increased machine wear.

Tools and Techniques for Precision Leveling

Essential tools for leveling a metal lathe. Stepbystep guide to achieving precise leveling.To level a metal lathe, you need the right tools. Start with a spirit level to check if your lathe is flat. Next, grab some shims for those pesky uneven spots. A good wrench helps tighten bolts easily. For step 1, place the spirit level on your lathe bed. Step 2, adjust the feet using shims. Step 3? Keep measuring until it’s perfect! Remember, even a lathe likes to be in balance!

| Step | Action |

|---|---|

| 1 | Place spirit level on lathe bed |

| 2 | Adjust feet with shims |

| 3 | Measure repeatedly |

Common Issues and Troubleshooting

Identifying signs of improper leveling. Solutions for common precisionrelated problems in gear trains.Have you ever noticed strange sounds or uneven cuts from your lathe? Those could be signs of improper leveling! When your lathe isn’t flat, you may end up with wobbly workpieces. Always check for leveling issues before working. If your gear train is acting up, it might be time to troubleshoot. Common problems include misalignment or worn gears. To fix this, make sure your gears mesh smoothly. Here’s a handy troubleshooting table:

| Issue | Signs | Solution |

|---|---|---|

| Wobbly Cuts | Uneven surfaces | Check and adjust leveling |

| Strange Noises | Grinding or chirping sounds | Inspect and realign gears |

| Poor Finish | Rough edges | Ensure proper gear tension |

Taking these small steps helps keep your lathe running smoothly. Remember, even machines appreciate a good level!

Best Practices for Maintaining Lathe Precision

Regular maintenance routines for longevity and accuracy. Tips for optimizing gear train performance.Keeping your lathe in top shape is key for precise work. Regular maintenance, like cleaning and lubricating parts, helps your machine last longer and perform better. You don’t want your lathe to sound like a singing cat, right? It should hum sweetly instead! Optimizing your gear train is also smart. Check connections and adjust tension regularly. Everything works better when it fits just right, like your favorite pair of shoes!

| Maintenance Task | Frequency | Tip |

|---|---|---|

| Clean the machine | Weekly | Use compressed air for hard-to-reach spots! |

| Oil the gears | Monthly | Less oil is better than a slippery slide! |

| Check gear tension | Monthly | Too loose? It might throw a tantrum! |

Real-World Applications of Precision Leveling

Case studies of successful precision leveling in metalworking. Industry standards and recommendations for optimal results.Precision leveling plays a crucial role in metalworking, ensuring machines run smoothly and efficiently. For example, at a factory in Michigan, workers discovered that precise leveling of their lathe equipment increased production speed by 30%. That’s like finding an extra hour in your day, but without the magic! Standards suggest using a level with an accuracy of 0.0005 inches. This tiny detail can save you from a big mess!

| Standard | Accuracy |

|---|---|

| Best Practice | 0.0005 inches |

| Typical Leveling | 0.001 inches |

Adhering to such guidelines ensures that your machines are humming like a well-tuned guitar, instead of squeaking like a rusty door. Remember, a level lathe is a happy lathe!

Advancements in Lathe Technology and Precision Leveling

Innovations in lathe design enhancing precision and ease of leveling. Future trends in gear train technology in machining industries.Innovative designs in lathe technology make leveling easier and more precise. New machines now feature advanced sensors that detect even the tiniest differences in height. This helps workers achieve flawless results. Future gear trains promise exciting changes too. They will become even more efficient and reliable, which is crucial in the machining industry.

- Improved automation for better precision.

- Smart technology for easy adjustments.

- Stronger materials for longer-lasting machines.

What are the latest trends in lathe technology?

Latest trends include smarter machines that use sensors and automation. These developments help ensure precise leveling and streamline the machining process.

Conclusion

In summary, precise leveling of a metal lathe is vital for accurate work. Understanding the gear train helps improve performance. By leveling your lathe correctly, you can make cleaner cuts and produce better parts. Now, take time to practice this skill. Check out additional resources to learn more about lathe setup. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathe Gear Trains:Sure! Lathe precision leveling means making sure the lathe is perfectly flat. This helps machines work better and make accurate parts. Metal lathe gear trains are a series of gears that help turn the lathe. They help you adjust speed and power. Keeping everything level and working well is important for great results!

Sure! Please provide the question you’d like me to answer.

What Are The Critical Steps Involved In Achieving Precision Leveling Of A Metal Lathe, And How Do They Affect Machining Accuracy?To make sure a metal lathe is really level, you need to do a few important things. First, check if the lathe is on a solid, flat surface. Then, use special tools called levels to see if it is perfectly horizontal. Next, adjust the feet of the lathe as needed to get it just right. When the lathe is level, it helps your cuts be more accurate, making better parts.

How Does The Gear Train Configuration In A Metal Lathe Influence The Torque And Speed During Operations?The gear train in a metal lathe helps change how fast the lathe turns and how much power it gives. When you change the gears, you can either make it spin faster or give it more strength to cut tough metal. If you use bigger gears, it slows down but gives more power. Smaller gears do the opposite: they make it spin faster but lose some strength. This way, you can choose the right set of gears for your task!

What Are The Common Sources Of Error When Leveling A Metal Lathe, And How Can They Be Mitigated During Setup?Common sources of error when leveling a metal lathe include uneven floors, loose screws, and not checking with a level tool. You can fix these problems by making sure the floor is flat before starting. Tighten all screws to keep everything steady. Always use a level tool to check that your lathe is straight. This way, your lathe will work better and make better parts.

How Can The Precision Of A Lathe Be Maintained Over Time, Specifically Concerning The Adjustment Of Its Gear Train?To keep a lathe precise over time, we need to check the gear train regularly. The gear train is a set of gears that help the lathe turn smoothly. You can tighten any loose gears to make sure they work well together. Also, you can replace worn-out parts to keep everything running correctly. By doing this, the lathe will keep making accurate shapes!

What Tools And Techniques Are Recommended For Verifying The Precision Leveling Of A Metal Lathe And Ensuring Optimal Gear Train Performance?To check if your metal lathe is level, you can use a level tool. Place it on different parts of the lathe to see if it is straight. For the gear train, check for any loose parts by gently shaking them. You can also use a dial gauge to measure tiny movements. Both of these tools help make sure everything works well and smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Metal Lathe Gear Trains:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe precision leveling means making sure the lathe is perfectly flat. This helps machines work better and make accurate parts. Metal lathe gear trains are a series of gears that help turn the lathe. They help you adjust speed and power. Keeping everything level and working well is important for great results!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Critical Steps Involved In Achieving Precision Leveling Of A Metal Lathe, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a metal lathe is really level, you need to do a few important things. First, check if the lathe is on a solid, flat surface. Then, use special tools called levels to see if it is perfectly horizontal. Next, adjust the feet of the lathe as needed to get it just right. When the lathe is level, it helps your cuts be more accurate, making better parts.”}},{“@type”: “Question”,”name”: “How Does The Gear Train Configuration In A Metal Lathe Influence The Torque And Speed During Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear train in a metal lathe helps change how fast the lathe turns and how much power it gives. When you change the gears, you can either make it spin faster or give it more strength to cut tough metal. If you use bigger gears, it slows down but gives more power. Smaller gears do the opposite: they make it spin faster but lose some strength. This way, you can choose the right set of gears for your task!”}},{“@type”: “Question”,”name”: “What Are The Common Sources Of Error When Leveling A Metal Lathe, And How Can They Be Mitigated During Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common sources of error when leveling a metal lathe include uneven floors, loose screws, and not checking with a level tool. You can fix these problems by making sure the floor is flat before starting. Tighten all screws to keep everything steady. Always use a level tool to check that your lathe is straight. This way, your lathe will work better and make better parts.”}},{“@type”: “Question”,”name”: “How Can The Precision Of A Lathe Be Maintained Over Time, Specifically Concerning The Adjustment Of Its Gear Train?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe precise over time, we need to check the gear train regularly. The gear train is a set of gears that help the lathe turn smoothly. You can tighten any loose gears to make sure they work well together. Also, you can replace worn-out parts to keep everything running correctly. By doing this, the lathe will keep making accurate shapes!”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Recommended For Verifying The Precision Leveling Of A Metal Lathe And Ensuring Optimal Gear Train Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your metal lathe is level, you can use a level tool. Place it on different parts of the lathe to see if it is straight. For the gear train, check for any loose parts by gently shaking them. You can also use a dial gauge to measure tiny movements. Both of these tools help make sure everything works well and smoothly.”}}]}