Have you ever wondered how metalworkers create such precise parts? It often starts with a metal lathe. A lathe is a powerful tool that shapes metal into beautiful forms. Yet, to make sure it works well, you need to level it correctly. Precision leveling is crucial. Just a tiny mistake can make a big difference.

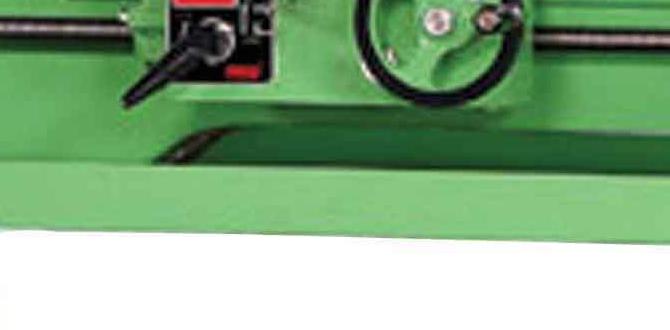

Imagine trying to build a model out of Lego blocks. If one block is uneven, the whole design will wobble. This is similar to what happens with a metal lathe. The handwheel is a key part of a lathe. It allows users to move the tool in small, exact steps. So, why is it important to have a well-leveled lathe with a smooth handwheel?

It’s simple. A leveled lathe helps produce accurate work. Whether you’re making parts for a toy or a piece of machinery, precision matters. Did you know that even a small bump can ruin an entire project? So, next time you see a metal lathe, remember that precision leveling is behind the magic of crafting detailed metal pieces.

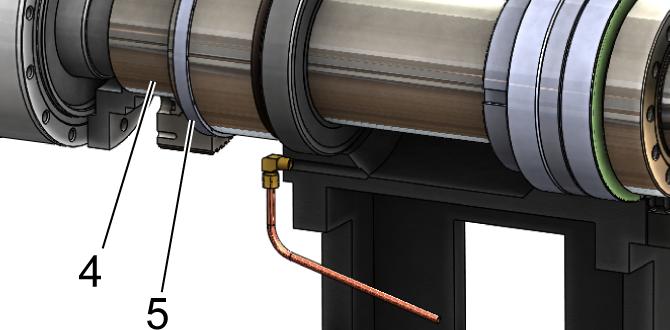

Lathe Precision Leveling: Enhancing Metal Lathe Handwheel Performance Introduction Precision Leveling Is A Crucial Aspect When It Comes To Maximizing The Performance Of A Metal Lathe, Particularly When Adjusting The Handwheel. Properly Leveling Your Lathe Not Only Ensures Accurate Cuts But Also Extends The Life Of Your Machine And Enhances Safety While Operating. Importance Of Lathe Precision Leveling Lathe Precision Leveling Is Essential For Achieving High-Quality Machining Results. When Your Lathe Is Level, It Reduces The Stress On The Machine’S Components, Leading To Less Wear And Tear. Additionally, A Well-Leveled Machine Minimizes Vibrations, Which Can Cause Inaccuracies In Your Work. Tools Required Before You Start The Leveling Process, Gather The Necessary Tools: – A Precision Level Or Machinist’S Level – Wrenches And Screwdrivers – Measuring Tape – A Flat, Stable Surface Steps To Level Your Metal Lathe 1. **Prepare The Work Area**: Ensure That Your Workspace Is Clean And Free From Debris. 2. **Check For Stability**: Place The Lathe On A Stable, Heavy-Duty Workbench That Can Support Its Weight. 3. **Using The Precision Level**: Place The Precision Level On The Bed Of The Lathe, First Checking Front To Back And Then Side To Side. 4. **Adjust The Leveling Feet**: Most Metal Lathes Come With Adjustable Feet. Use Your Wrenches To Raise Or Lower These Feet Until The Lathe Is Level In Both Directions. 5. **Recheck**: Once Adjustments Are Made, Check The Level Again To Ensure It Remains Consistent. 6. **Final Adjustment Of The Handwheel**: Properly Aligning The Handwheel Is Vital For Smooth Operation. Make Fine Adjustments To Ensure It’S Easy To Rotate And Responsive. Conclusion Proper Lathe Precision Leveling Can Significantly Affect The Functionality And Efficiency Of Your Metal Lathe. By Following These Steps, You Not Only Improve The Performance Of Your Machine But Also Ensure Safety During Operations. Regular Checks And Adjustments Will Lead To Long-Lasting Benefits, Optimizing Your Machining Projects And Keeping Your Equipment In Excellent Working Condition.

Lathe Precision Leveling: Enhancing Your Metalwork

Achieving precision with a metal lathe can seem challenging. But did you know a well-leveled lathe can drastically improve your work? The lathe precision leveling method involves adjusting the handwheel carefully. This ensures the lathe is stable and cuts accurately. Accurate leveling leads to smoother operations and better finishes. Imagine crafting a perfect piece on your lathe! You’ll spend less time fixing mistakes and more time creating. Embrace the art of leveling for superior results.Understanding Lathe Precision Leveling

Definition and importance of precision leveling in machining. How precision leveling affects metalworking accuracy and quality.Precision leveling is like putting on your favorite pair of shoes before a dance. It ensures your lathe is stable and aligned for the best performance. This step is vital in machining, as even a tiny error can lead to big problems! Proper leveling boosts accuracy and improves quality in metalworking. Without it, your projects may wobble more than a cat on a hot tin roof, ruining your hard work. For those who love numbers, 0.001 of an inch can make or break a piece!

| Key Point | Impact |

|---|---|

| Definition of Precision Leveling | Aligns machinery for better function. |

| Importance | Improves accuracy and quality. |

Tools and Equipment Needed for Leveling

List of required tools for precision leveling. Recommended leveling devices and accessories.To achieve perfect leveling, you need the right tools. Here’s a simple list:

- Spirit Level

- Calibration Bars

- Dial Indicator

- Adjustable Wrenches

- Metal Feeler Gauges

Using quality leveling devices and accessories is key. They help ensure a sturdy setup. For best results, think about using:

- Snap Level

- Laser Level

- Precision Straightedge

Having these tools makes the leveling process much easier!

What tools are best for precision leveling?

It’s best to use a spirit level, calibration bars, and a dial indicator. These tools help measure and adjust your lathe accurately. With the right tools, your lathe will work better and last longer!

Step-by-Step Guide to Leveling Your Metal Lathe

Preparatory steps before leveling. Detailed instructions on adjusting the lathe for precision leveling.Before you tackle leveling a metal lathe, gather your tools and take a deep breath. First, check the floor—no, not for snacks! Make sure it’s solid and even. Next, eye the lathe; is it on a stable surface? If it’s wobbling like Jelly, we’ve got a problem. Here’s a quick overview of steps:

| Step | Action |

|---|---|

| 1 | Clear the area around the lathe. |

| 2 | Use a level to check the lathe’s base. |

| 3 | Adjust feet or add shims for precise leveling. |

| 4 | Double-check with the level. |

To precisely level, begin at one corner. Adjust the handwheel while watching your level. If it teeters like a tightrope walker, keep fine-tuning until it sits straight. Remember, a level lathe is a happy lathe!

Maintaining Lathe Precision After Initial Setup

Recommended practices for ongoing maintenance of leveling. Importance of regular checks and adjustments.To keep your lathe performing like a superstar, regular checking and adjusting are key. Think of it as giving your lathe a little hug of care! Check the leveling often, as changes in temperature or conditions can throw it off. Little adjustments can save you big headaches. Keep an eye on the handwheel, too; it likes to spin just right. A well-maintained lathe not only runs smoother but can also last longer. Who doesn’t want their tools to stay fit and happy?

| Maintenance Tip | Frequency |

|---|---|

| Check Leveling | Every week |

| Inspect Handwheel | Every month |

| Adjust for Temperature | As needed |

Remember, a little care now means a lot less worry later! Just like a favorite toy, your lathe deserves a little love.

Advanced Techniques for Enhanced Lathe Precision

Techniques for experienced users to further improve precision. Importance of calibration and monitoring precision over time.To take your lathe skills to the next level, focus on the art of calibration. Regularly adjusting your machine ensures it stays in tip-top shape. Think of it as giving your lathe a spa day! Keep an eye on the precision over time. Small mistakes can add up, like crumbs on your favorite cookie. A few tweaks can make a huge difference in accuracy.

| Technique | Description |

|---|---|

| Calibration | Adjust settings regularly to keep the lathe precise. |

| Monitoring | Check precision frequently to catch small errors. |

By keeping up with these methods, you can smooth out those pesky bumps and make your projects shine! Always remember, a great lathe is a happy lathe!

Troubleshooting Leveling Issues

Common leveling problems and their solutions. Signs that indicate the need for immediate releveling.Leveling your lathe can sometimes feel like playing a game of hide-and-seek. Common problems include uneven placement. If one leg of your lathe is shorter, expect your projects to wobble like a jelly! Another sign is strange noises when using the handwheel. Can’t find a comfy spot? Check if the floor is even. If you don’t see daylight under the legs, it’s time for a relevel!

| Common Problems | Signs You Need Releveling |

|---|---|

| Uneven legs | Wobbling workpieces |

| Floor slope | Unusual sounds |

| Incorrect handwheel movement | Difficulty in making precise cuts |

Conclusion

In summary, using a lathe requires precise leveling for best results. The metal lathe handwheel helps you adjust settings easily. Remember to check your setup before starting a project. This ensures accuracy and smooth operation. For more tips, consider researching lathe maintenance or watch helpful videos. You can improve your skills by practicing regularly. Happy machining!FAQs

What Are The Best Practices For Leveling A Metal Lathe To Ensure Precision During Machining Operations?To level a metal lathe, you should first find a flat surface. Use a level tool to check if the lathe is straight. Adjust the legs of the lathe until it is even. Tighten all the bolts to keep it steady. Finally, double-check that everything looks good before you start working.

How Does The Condition Of The Handwheel Affect The Precision Leveling Of A Lathe?The handwheel helps you adjust the lathe to make sure it’s level. If the handwheel is worn out or loose, it’s hard to get the lathe perfectly level. This can make your work less accurate. A good handwheel lets you make small changes easily, keeping your work precise. Always check the handwheel to keep everything working well!

What Tools And Instruments Are Recommended For Accurately Leveling A Metal Lathe?To level a metal lathe, you need a few simple tools. A spirit level helps check if the lathe is balanced. You can also use precision measuring tools like a height gauge. A soft-faced hammer can help adjust the lathe’s feet. These tools make sure your lathe works well and stays straight while you use it!

How Often Should A Metal Lathe Be Re-Leveled To Maintain Optimal Precision And Performance?You should re-level a metal lathe every few months. You might need to do it more often if you move it or if you notice problems. Check the level if you see parts not fitting together right. Keeping it level helps make sure your work is precise and smooth.

What Common Issues Can Arise From Improper Leveling Of A Lathe, And How Can They Be Mitigated?If a lathe isn’t level, it can cause problems like shaky cuts or parts that aren’t shaped right. These issues can make your work messier and less accurate. To avoid this, always use a level tool to check the lathe before starting. You can also adjust the feet of the lathe to make sure it’s flat and stable.