Have you ever wondered how metal lathes make such accurate parts? One important factor is the lathe precision leveling. This process helps keep the machine straight and balanced. Without it, your projects might turn out crooked or uneven.

Imagine trying to build a model airplane. If one wing is longer than the other, the plane won’t fly right. The same idea applies to metal lathes and their lead screws. The lead screw is what moves the cutting tool. If it’s not level, the tool won’t cut smoothly.

Did you know that even a tiny mistake can lead to big problems? That’s why properly leveling your lathe matters. It ensures that every piece you create is perfect. In this article, we’ll explore how to achieve lathe precision leveling and understand the importance of the lead screw.

Let’s dive in and discover how to make your metal lathe work at its best!

Lathe Precision Leveling: Metal Lathe Lead Screw Tips

Understanding Lathe Precision Leveling and Lead Screws

Lathe precision leveling helps ensure your metal lathe runs smoothly. It keeps the machine steady and reduces errors in cutting. A well-leveled lathe allows for accurate measurements, making your projects more precise.

Lead screws play a crucial role in the lathe’s movement. They help in moving the cutting tool with exactness. Did you know that a tiny misalignment can lead to significant mistakes in your work? Keeping your lathe level is key to preventing that!

Understanding Lathe Precision Leveling

Importance of precision leveling in metalworking. Impact on machining accuracy and surface finish.Proper leveling is key in metalworking. It helps make sure machines, like lathes, work accurately. If a lathe is not level, parts can come out crooked or rough. This means precision leveling is vital for quality. A well-leveled lathe can:

- Improve machining accuracy.

- Enhance surface finish.

- Reduce wear on tools.

In fact, even a tiny mistake can lead to big problems. Making sure your lathe is level can save time and money.

Why is precision leveling important?

Precision leveling is important because it affects the quality of finished parts. A level lathe leads to better cuts and reduces mistakes.

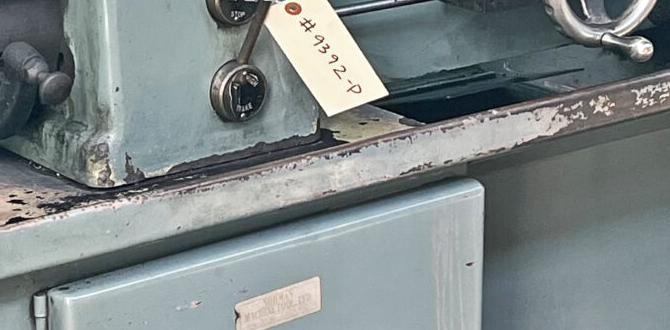

The Role of the Lead Screw in Metal Lathes

Function and significance of lead screws in lathes. Types of lead screws used in metal lathes.The lead screw is like the trusty sidekick of a metal lathe. It helps move the tool back and forth, making sure everything is just right. Without it, your lathe would be like a car without wheels—unable to go anywhere! There are different types of lead screws too, each with unique benefits. For example, Acme screws are strong and great for heavy jobs, while square-thread screws work well for fine movements. This variety allows you to pick the perfect screw for your task!

| Type of Lead Screw | Description |

|---|---|

| Acme Screw | Strong and ideal for heavy loads. |

| Square-Thread Screw | Best for precise movements. |

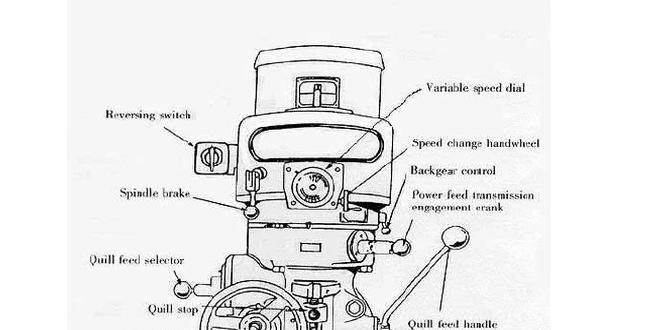

Tools and Equipment for Precision Leveling

Essential tools for effective leveling. Choosing the right leveling equipment for your lathe.To level your lathe correctly, you need the right tools. These tools help keep your work accurate and neat. Here are some essential tools:

- Tape measure for measuring distances.

- Level to check if the machine is flat.

- Alignment bars to keep everything straight.

- Wrenches for tightening bolts.

- Digital indicators for precise readouts.

Choosing the right equipment is key. Look for tools made for metal lathes. High-quality tools offer better accuracy. Always make sure your tools are easy to use. This will make leveling easier and more effective.

What tools do you need for precision leveling?

You need a tape measure, a level, alignment bars, wrenches, and digital indicators for precision leveling.

Step-by-Step Guide to Leveling Your Metal Lathe

Preparing the workspace and lathe for leveling. Detailed leveling procedure with tips for accuracy.Before leveling your metal lathe, make sure your workspace is clean and organized. A tidy area helps you focus. Next, check the lathe for any damage. It should be stable and secure. To start leveling, use a machinist’s level. Place it on the bed of the lathe. Adjust the feet until the bubble is centered. Accuracy is key here. Use shims if needed to achieve the right height.

How to Prepare Your Lathe for Leveling?

Start by removing any clutter around the lathe. Check that all parts are working and tight. Clean the bed to avoid debris.

Tips for Leveling:

- Check for any wobbly parts.

- Use a good-quality level.

- Adjust slowly for better precision.

Maintenance Tips for Lead Screws on Metal Lathes

Best practices for lead screw maintenance. Signs that indicate lead screw issues and how to address them.To keep lead screws working well, follow some easy maintenance tips. Clean the screws and check for wear. Lubricate them regularly for smoother movement. Watch for signs of trouble, like strange noises or uneven turning. These may indicate a problem. Address issues quickly to avoid bigger repairs.

- Check for dirt and debris.

- Lubricate every few months.

- Listen for unusual sounds.

- Observe movement for smoothness.

What are common lead screw issues?

Common issues include wear, binding, and noise. Address them by cleaning, lubricating, or replacing parts.

Key Signs of Lead Screw Problems

- Inconsistent movement

- Unusual sounds

- Visible wear or damage

Enhancing Longevity and Performance of Your Lathe

Routine checks and adjustments for optimal performance. Upgrades and modifications to improve precision in machining.Taking care of your lathe is like giving it a warm hug! Regular checks keep everything smooth. Start by looking at the lead screw; it’s your lathe’s best friend. Check for wear and tear. A little adjustment here and there can make a big difference in performance. Upgrading to newer technology can boost precision, turning your lathe into a machining superstar! Remember, a happy lathe means happy projects!

| Routine Checks | Upgrades |

|---|---|

| Inspect lead screw for damage | Consider adding digital readouts |

| Lubricate regularly | Upgrade to precision bearing |

| Align the bed | Add anti-backlash nuts |

Conclusion

In summary, leveling your metal lathe is crucial for accuracy. The lead screw plays a key role in this process. By ensuring proper alignment, you improve the quality of your work. Take time to check your setup often. For more tips on lathe maintenance, consider exploring related articles. Let’s keep our projects precise and enjoyable!FAQs

What Are The Key Considerations For Achieving Precision Leveling Of A Metal Lathe During Setup?To set up a metal lathe, you need to make it level. First, check the floor where you place the lathe. It should be strong and flat. Use a level tool to see if the lathe is even from side to side and front to back. You can adjust the legs of the lathe to make it match. This helps the lathe work better and make accurate parts.

How Does Lead Screw Alignment Affect The Overall Accuracy Of A Metal Lathe’S Machining Operations?Lead screw alignment is very important for a metal lathe. If it’s not lined up right, the machine can make mistakes. This can cause parts to be too big or too small. When the lead screw is straight, it helps the lathe work correctly. So, good alignment means more accurate machines and better parts.

What Tools And Techniques Are Commonly Used To Level A Metal Lathe For Optimal Performance?To level a metal lathe, you can use bubble levels or machinist levels. First, you place the level on the bed of the lathe. Then, adjust the feet of the lathe until the bubble sits in the middle. You might also use shims to help keep it steady. Checking it again after adjustments will make sure it’s perfect!

How Often Should A Metal Lathe Be Re-Leveled To Maintain Precision In Machining?You should re-level your metal lathe regularly to keep it working well. It’s a good idea to do this every few weeks if you use it often. If you move it or notice any changes, re-level it right away. This helps you make precise cuts and keeps your projects looking great!

What Are The Potential Consequences Of An Improperly Leveled Lead Screw In A Metal Lathe?If the lead screw on a metal lathe isn’t leveled correctly, it can cause problems. Your cuts may not be straight, and the pieces can turn out uneven. This means you might waste metal and time fixing mistakes. You could also damage the lathe if it works too hard. Always check the level to keep your work safe and smooth!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Considerations For Achieving Precision Leveling Of A Metal Lathe During Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, you need to make it level. First, check the floor where you place the lathe. It should be strong and flat. Use a level tool to see if the lathe is even from side to side and front to back. You can adjust the legs of the lathe to make it match. This helps the lathe work better and make accurate parts.”}},{“@type”: “Question”,”name”: “How Does Lead Screw Alignment Affect The Overall Accuracy Of A Metal Lathe’S Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lead screw alignment is very important for a metal lathe. If it’s not lined up right, the machine can make mistakes. This can cause parts to be too big or too small. When the lead screw is straight, it helps the lathe work correctly. So, good alignment means more accurate machines and better parts.”}},{“@type”: “Question”,”name”: “What Tools And Techniques Are Commonly Used To Level A Metal Lathe For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you can use bubble levels or machinist levels. First, you place the level on the bed of the lathe. Then, adjust the feet of the lathe until the bubble sits in the middle. You might also use shims to help keep it steady. Checking it again after adjustments will make sure it’s perfect!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Re-Leveled To Maintain Precision In Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should re-level your metal lathe regularly to keep it working well. It’s a good idea to do this every few weeks if you use it often. If you move it or notice any changes, re-level it right away. This helps you make precise cuts and keeps your projects looking great!”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of An Improperly Leveled Lead Screw In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lead screw on a metal lathe isn’t leveled correctly, it can cause problems. Your cuts may not be straight, and the pieces can turn out uneven. This means you might waste metal and time fixing mistakes. You could also damage the lathe if it works too hard. Always check the level to keep your work safe and smooth!”}}]}