Imagine a craftsman in a workshop, surrounded by tools and machinery. One of the most crucial tools is the lathe. It shapes metal into precise forms. But did you know that lathe precision leveling is key for perfect outcomes? Without it, your work may turn out wobbly or uneven.

Many metalworkers overlook lathe maintenance. They might think, “Why bother?” But skipping this step can lead to big problems later. Just like your favorite bike needs air in the tires, lathes require regular care. A small adjustment can make a huge difference.

In this article, we will dive into lathe precision leveling and maintenance. We will explore simple tips to keep your metal lathe in top shape. You’ll learn how easy it is to improve your projects. Are you ready to unlock the full potential of your lathe? Let’s get started!

Lathe Precision Leveling: Essential Metal Lathe Maintenance Tips

Understanding Lathe Precision Leveling and Maintenance

Imagine spinning metal and creating perfect shapes. This is what a lathe does! To achieve great results, you need lathe precision leveling. This means setting up the lathe just right for accuracy. Regular maintenance is key too. It helps keep everything working smoothly. By checking the bed, tailstock, and spindle often, you prevent costly mistakes. Keeping your metal lathe in top shape ensures your projects turn out perfectly every time.Understanding Lathe Precision

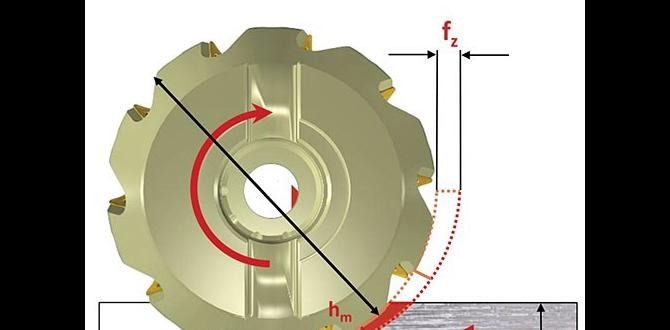

Definition of lathe precision. Importance of precision in metalworking.Lathe precision means how exact a lathe can shape or cut metal. It affects how well tools work. Precision is key in metalworking because it ensures pieces fit perfectly. This means parts work better, last longer, and reduce waste.

- Exact measurements lead to better quality.

- Precision parts improve machinery efficiency.

- Less waste means more savings.

Without precision, even small mistakes can ruin a project.

Why is precision important in metalworking?

Precision ensures high quality and efficiency, leading to cost savings and better overall performance.

The Basics of Lathe Leveling

Key principles of leveling a metal lathe. Tools and materials needed for effective leveling.Leveling a metal lathe is key to precision work. Proper leveling helps avoid mistakes and keeps the machine running smoothly. Start with a stable, flat surface. Use a spirit level for accuracy. Adjust the feet of the lathe until it is level. Check again after each adjustment. Essential tools include:

- A spirit level

- Adjustable wrenches

- Shims

These will help you achieve the best results.

How do you know if a lathe is level?

Check the bubble in the spirit level. If it is centered, your lathe is level. Adjust the legs until it is just right.

Step-by-Step Guide to Leveling Your Metal Lathe

Preparing the workspace for leveling. Detailed leveling procedure, including adjustments and checks.First, clear your workspace. Remove tools and debris to prevent accidents. Next, check the lathe’s manual for specific instructions. Here’s a simple leveling procedure:

- Use a level tool on the bed of the lathe.

- Adjust the legs up or down as needed.

- Re-check the level in multiple spots.

- Tighten all screws and connections.

- Test the machine with a piece of scrap metal.

This ensures your lathe stays straight and functions well. Regular checks can help avoid problems later!

What is the best way to maintain a metal lathe?

The best way to maintain a metal lathe is by cleaning it regularly, checking for wear, and lubricating moving parts. Regular maintenance keeps your lathe in good working order.

Common Issues Caused by Improper Leveling

Effects on machining accuracy and surface finish. How to identify levelingrelated problems.Improper leveling can lead to some serious mischief on your lathe. Your machining accuracy may take a vacation, and the surface finish might look worse than a pizza gone wrong. To spot these pesky problems, keep an eye out for strange noises or uneven cuts—these are like warning signs saying, “Fix me!” Also, regular checks can save you from turning your metal into Swiss cheese.

| Signs of Leveling Issues | Effects on Machining |

|---|---|

| Uneven cuts | Increased scrap rate |

| Strange noises | Poor surface finish |

| Vibrations | Reduced tool life |

Remember, a little leveling goes a long way! Your lathe will thank you with smoother finishes and happier machining adventures.

Regular Maintenance for Optimal Lathe Performance

Checklist for routine maintenance tasks. Importance of lubrication and cleaning.Keeping your lathe in tip-top shape is like taking care of a pet. You need to feed it, clean it, and give it some love! A simple checklist helps here. Check the belt tension, inspect the tool holders, and look for wear and tear. Don’t forget to wipe it down regularly. A clean machine is a happy machine! Plus, lubrication is crucial; it helps parts glide smoothly. Imagine trying to skate in sand—yikes! Regular maintenance keeps your lathe buzzing and free from those awful grindy sounds!

| Maintenance Task | Frequency |

|---|---|

| Check belt tension | Weekly |

| Inspect tool holders | Monthly |

| Clean surfaces | Every use |

| Lubricate parts | Weekly |

Advanced Maintenance Techniques for Longevity

Indepth look at components requiring regular inspection. Tips for troubleshooting and repairing common issues.For your lathe to last, check its parts regularly. Key components include:

- Headstock: Look for wear and noise.

- Tailstock: Ensure it moves smoothly.

- Tool rest: Check for damage or rust.

- Oil squeaky parts.

- Tighten loose screws.

- Replace broken belts.

What parts need regular inspection on a lathe?

Key parts include the headstock, tailstock, and tool rest. Each needs attention to avoid problems.

How can I troubleshoot common lathe issues?

Check for noise, movement, and damaged parts. Simple fixes can solve many problems.

Upgrading Your Lathe for Better Precision

Recommended upgrades to enhance precision. Costeffective solutions for improved performance.Making your lathe better can help your projects a lot! There are simple upgrades that you can do without spending a fortune. Here are some effective suggestions:

- Install a quality tailstock alignment tool for precision.

- Add a digital readout for quicker measurements.

- Use better cutting tools to reduce wear.

- Upgrade the motor for increased power.

These upgrades can boost your lathe’s performance while keeping costs low. Small changes can lead to big improvements!

What upgrades improve lathe performance?

Using a better tailstock alignment tool and adding a digital readout can improve precision.

Resources for Further Learning

Recommended books and online courses on lathe maintenance. Professional organizations and forums for lathe enthusiasts.Many resources can help you learn more about lathe maintenance. Check out these recommended books and online courses:

- “Lathe Basics: A Complete Guide”

- “Metalworking for Beginners” (online course)

- “Advanced Lathe Techniques”

Additionally, join professional organizations and forums. This helps you connect with other lathe lovers. Here are some good options:

- American Association of Woodturners

- Lathe Users Forum

Where can you find courses on lathe maintenance?

You can find many courses by searching online. Websites like Udemy and Coursera offer great lessons about lathe care.

Conclusion

In conclusion, properly leveling your metal lathe is essential for precision work. Regular maintenance keeps your machine running smoothly and improves results. You should check the level often and clean parts regularly. Remember, small steps can lead to big improvements. For more tips on lathe care, consider reading guides and watching videos. Start taking better care of your lathe today!FAQs

What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe?To achieve precision leveling on a metal lathe, start by checking the floor under the machine. Make sure it’s flat and solid. Use a level tool to see if the lathe is straight. Adjust the feet or legs of the lathe until it’s level. This helps your work stay accurate and smooth.

How Often Should A Metal Lathe Be Leveled And Calibrated For Optimal Performance?You should level and calibrate a metal lathe every few months. If you use it a lot, do this more often. Check it whenever it moves or gets bumped. Keeping it level helps the lathe work better and makes your projects turn out nice!

What Tools Are Necessary For Maintaining And Leveling A Metal Lathe Effectively?To keep a metal lathe in good shape, you need a few important tools. First, a level helps you check if the lathe is flat and balanced. You also need a wrench to tighten any loose parts. A clean cloth is great for wiping away dirt and oil. Finally, measuring tools help you check everything is the right size.

How Does Improper Leveling Affect The Accuracy And Lifespan Of A Metal Lathe?When a metal lathe isn’t level, it can cause problems. The metal piece might not be cut correctly, leading to mistakes in your work. This can make your projects look bad or not work well. Over time, these problems can wear out the lathe faster, making it break sooner. Keeping it level helps you make great parts and keeps the lathe working longer.

What Are Common Signs That Indicate A Metal Lathe Needs Maintenance Or Realignment?You might notice a few signs that your metal lathe needs some care. First, if your machine makes strange noises or vibrations, it could be time for maintenance. Second, if the cuts on your metal aren’t smooth, the lathe might be out of alignment. Lastly, if you see any rust or debris, clean it up and check if it needs help. Regular checks can keep your lathe working well!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling on a metal lathe, start by checking the floor under the machine. Make sure it’s flat and solid. Use a level tool to see if the lathe is straight. Adjust the feet or legs of the lathe until it’s level. This helps your work stay accurate and smooth.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Leveled And Calibrated For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should level and calibrate a metal lathe every few months. If you use it a lot, do this more often. Check it whenever it moves or gets bumped. Keeping it level helps the lathe work better and makes your projects turn out nice!”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Maintaining And Leveling A Metal Lathe Effectively? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe in good shape, you need a few important tools. First, a level helps you check if the lathe is flat and balanced. You also need a wrench to tighten any loose parts. A clean cloth is great for wiping away dirt and oil. Finally, measuring tools help you check everything is the right size.”}},{“@type”: “Question”,”name”: “How Does Improper Leveling Affect The Accuracy And Lifespan Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When a metal lathe isn’t level, it can cause problems. The metal piece might not be cut correctly, leading to mistakes in your work. This can make your projects look bad or not work well. Over time, these problems can wear out the lathe faster, making it break sooner. Keeping it level helps you make great parts and keeps the lathe working longer.”}},{“@type”: “Question”,”name”: “What Are Common Signs That Indicate A Metal Lathe Needs Maintenance Or Realignment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a few signs that your metal lathe needs some care. First, if your machine makes strange noises or vibrations, it could be time for maintenance. Second, if the cuts on your metal aren’t smooth, the lathe might be out of alignment. Lastly, if you see any rust or debris, clean it up and check if it needs help. Regular checks can keep your lathe working well!”}}]}