Imagine you’re in a workshop, surrounded by tools and machines. You’re about to create something amazing with a metal lathe. But wait! Have you leveled your lathe properly? Precision leveling is key to success in any metal lathe operation.

When your lathe is not level, your work can go off track. Poor leveling leads to mistakes and wasted materials. Did you know that a tiny mistake can turn a simple task into a big problem? By understanding how to level your lathe, you set yourself up for clear cuts and smooth finishes.

Whether you’re a seasoned machinist or just starting, getting the leveling right will boost your skills. So, what makes lathe precision leveling so crucial in metal lathe operations? Let’s explore this fascinating topic and unlock the secrets to successful machining.

Lathe Precision Leveling For Enhanced Metal Lathe Operations

Lathe Precision Leveling in Metal Lathe Operations

Precision leveling is key to successful metal lathe operations. When a lathe is not level, it can produce inaccurate parts. This leads to wasted time and materials. Have you ever wondered how much a tiny tilt could affect your project? Even a small adjustment can boost quality. Properly leveling the lathe ensures smooth operation and extends its lifespan. A well-leveled lathe can save you from frustrating rework and give you confidence in your craftsmanship.Understanding Lathe Precision Leveling

Importance of leveling for accuracy and reliability.. Factors affecting lathe precision..Leveling a lathe is like putting on your favorite pair of shoes. It keeps everything balanced and running smoothly. Without proper leveling, your projects might end up looking lopsided, and nobody wants a wonky table! Accuracy is key, as a well-leveled lathe increases reliability in metalworking. Factors affecting precision include floor stability, machine weight, and even temperature changes. Don’t let your lathe give you the wobbles!

| Factor | Impact on Precision |

|---|---|

| Floor Stability | Affects balance and vibration |

| Machine Weight | Influences stability and rigidity |

| Temperature Changes | Can cause expansion or contraction |

Step-by-Step Guide to Leveling Your Metal Lathe

Initial setup: Preparing the workspace and lathe.. Detailed leveling process: Techniques and adjustments..Before diving into leveling your metal lathe, make sure your workspace is tidy. A clean area helps avoid accidents, like tripping over that rogue skateboard from last summer! Start by placing your lathe on a sturdy, flat surface. Now, pull out your trusty spirit level. It’s like a magic tool that tells you if things are straight!

To level the lathe, adjust the feet with your hands or a wrench, depending on your lathe’s design. Check the bubble in your spirit level; it should sit right between the lines. If it’s not, you’re in for a mini workout! Repeat this until the bubble behaves like a well-trained puppy — centered and calm.

| Step | Action |

|---|---|

| 1 | Clear the workspace |

| 2 | Place lathe on a flat surface |

| 3 | Use spirit level for adjustments |

| 4 | Ensure bubble is centered |

Lastly, always double-check your work. Unless you enjoy riding the rollercoaster of wonky cuts! Keep your lathe level for precision in all your projects.

Common Issues Caused by Improper Leveling

Effects on machining accuracy and finish.. Identifying symptoms of improper leveling..Improper leveling can lead to serious issues during metal lathe operations. It affects machining accuracy and the final finish, making your project look like it was made by a toddler! You might notice uneven cuts, chatter, or even parts not fitting together right. Symptoms can include vibrations and poor surface quality. Remember, your lathe is like a delicate dance partner; if it’s not level, you’ll be stepping on toes! Here’s a quick table to spot these signs:

| Symptom | Effect |

|---|---|

| Uneven cuts | Poor accuracy |

| Vibrations | Bad finish |

| Parts not fitting | Frustration levels soaring |

So, keep that lathe level, or you might end up with more scrap than success!

Maintenance Tips for Ensuring Long-Term Precision

Regular checks and adjustments.. Best practices for lathe upkeep..To keep your lathe running smoothly, regular checks are a must. Think of it like visiting the doctor for check-ups but with fewer needles! Adjust your lathe frequently; a tiny tweak can make a big difference. Use a level to ensure everything stays just right.

Follow best practices for upkeep. Always clean your machine after use; shavings love to hide in corners. Lubricate moving parts, so they don’t feel like they’re walking through molasses. And remember, a happy lathe makes for happier projects! Check out the handy table below for a quick overview of maintenance tasks:

| Task | Frequency |

|---|---|

| Clean machine | After each use |

| Check alignment | Weekly |

| Lubricate parts | Monthly |

Keep these steps in mind, and your lathe will serve you faithfully for years. Remember, it’s not only about work; it’s about working smart!

Advanced Techniques for Experienced Operators

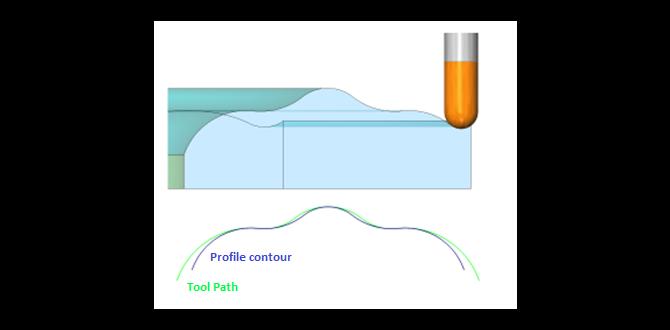

Finetuning and adjustments for specialized operations.. Incorporating technology for enhanced precision..Experienced operators can improve their skills through finetuning and adjustments. Small changes can make a big difference in results. Using technology boosts precision during operations. Tools like digital readouts help track measurements accurately. Find specialized techniques to get the best performance from your metal lathe.

- Use calibration tools for accurate settings.

- Incorporate software for better control.

- Regularly check for wear and tear on parts.

How can technology improve metal lathe operations?

Technology can enhance precision and efficiency. Machines equipped with sensors and digital displays help operators make real-time adjustments. This results in tighter tolerances and better finishes.

Case Studies: Successful Metal Lathe Operations

Examples of projects benefitting from precision leveling.. Lessons learned from experienced machinists..Many projects shine thanks to precision leveling in metal lathe operations. For instance, a clockmaker once crafted a beautiful watch with tiny gears that fit perfectly. Thanks to precise leveling, those gears moved smoothly. Experienced machinists share lessons learned too. They say, “Leveling is like leveling your bed; it keeps you from rolling off!” In a nutshell, leveling can make the difference between a masterpiece and a mess.

| Project | Benefit of Precision Leveling | Lesson Learned |

|---|---|---|

| Clock Making | Improved gear movement | Precision is key! |

| Automotive Parts | Better fit and function | Level before you start! |

| Tool Manufacturing | Increased accuracy | Small changes yield big results! |

Conclusion

In summary, leveling your metal lathe ensures accurate cuts and better results in your projects. It helps maintain precision and improves your overall work quality. Remember to check your lathe regularly and adjust as needed. For more tips on lathe operations, explore articles or videos that can guide you further. Happy machining!FAQs

What Are The Essential Steps For Achieving Precision Leveling On A Metal Lathe Before Starting Operations?To achieve precision leveling on a metal lathe, first, find a flat and sturdy surface for the machine. Next, use a level tool to check if the lathe is even. You might need to adjust the feet of the lathe to make it level. Tighten all screws and bolts once it’s level. Finally, double-check the level again to be sure.

How Does The Alignment And Leveling Of A Lathe Affect The Accuracy Of Machining Operations?When we align and level a lathe, we make sure it’s straight and flat. This helps the machine cut exactly where we want it to. If the lathe is not level, it can create mistakes in the shapes we make. Keeping it aligned means our parts will fit together better. So, good alignment and leveling help us do better work!

What Tools And Techniques Are Recommended For Checking And Adjusting The Level Of A Metal Lathe?To check and adjust the level of a metal lathe, you will need a spirit level and some shims. First, place the spirit level on the lathe’s bed to see if it’s level. If it is not, add shims under the feet of the lathe to lift it up. Keep checking with the spirit level until it is straight. This makes sure your lathe works correctly!

How Can Uneven Flooring Impact The Leveling Process And Overall Performance Of A Metal Lathe?Uneven flooring can make it hard to level a metal lathe. If the lathe isn’t level, it won’t work well. You might get wobbly cuts or uneven shapes. This can mess up your projects. It’s important to make sure the floor is smooth to help the lathe run better.

What Maintenance Practices Can Help Maintain Precision Leveling During Regular Metal Lathe Operations?To keep your metal lathe level and working well, you should check it often. Start by cleaning it regularly to remove dust and metal shavings. You should also tighten bolts to prevent loose parts. Always make sure the lathe is on a flat surface. Finally, look for wear and tear on the parts and fix them if needed.