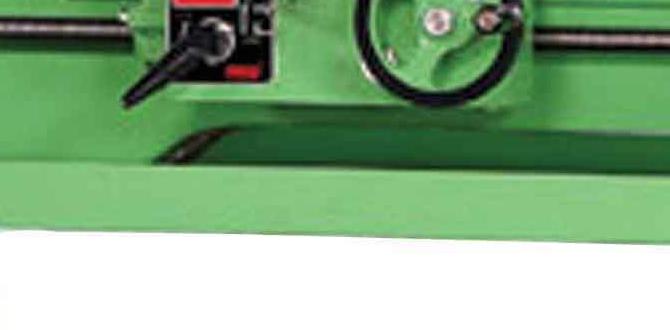

Have you ever wondered how machines make such precise parts? One key to their success is lathe precision leveling. When you work with metal lathe parts, accuracy becomes crucial. Even a tiny mistake can lead to a big problem.

Imagine trying to carve a statue from a block of stone. If your tools aren’t level, your sculpture might turn out all wrong. The same is true for metal cutting lathes. Proper leveling ensures smooth operation and perfect results.

Did you know that a well-leveled lathe can increase its lifespan? It can also save you time and money in repairs. In this article, we will explore the importance of lathe precision leveling and the various metal lathe parts involved. By learning these tips, you can improve your skills and get better outcomes in your projects.

Lathe Precision Leveling: Essential Metal Lathe Parts Guide

Lathe Precision Leveling for Metal Lathe Parts

Maintaining precision in your metal lathe is crucial. Proper leveling of lathe parts ensures accuracy and consistent performance. Have you ever wondered why some projects turn out better than others? It often comes down to this simple step. When lathe parts are aligned correctly, you avoid errors that can ruin your work. Surprisingly, just a few adjustments can make a huge difference. Remember, a well-leveled lathe leads to better results and happier users!Understanding Lathe Precision Leveling

Definition and importance of precision leveling. Common techniques for achieving precision in lathe setup.Precision leveling on a lathe is the magical trick that makes sure everything spins just right. Think of it as tuning a guitar – if it’s off, the song sounds terrible! This process helps to align parts properly so you can create smooth, accurate cuts. Common techniques include using leveling feet or a bubble level. These methods help keep everything in place and at the perfect angle. Remember, a well-leveled lathe is a happy lathe, and happy lathes make great parts!

| Technique | Description |

|---|---|

| Leveling Feet | Adjustable feet that can stabilize the lathe and correct any uneven surfaces. |

| Bubble Level | A simple tool used to find out if the lathe is level from side to side and front to back. |

Importance of Proper Lathe Setup

Effects of improper setup on machining accuracy. Best practices for setting up lathes for optimal performance.Setting up a lathe correctly is key to making precise parts. An improper setup can lead to mistakes and wasted materials. This not only costs money but also time. Follow these best practices:

- Check the level of your lathe regularly.

- Use proper tools to align parts.

- Make sure everything is clean and free of debris.

By taking these steps, you will enjoy better accuracy and smooth operation.

How does improper setup affect machining accuracy?

It can cause uneven cuts and poor finishes. This leads to parts that do not fit correctly or wear out quickly.

What are the best practices for lathe setup?

- Check level regularly. Ensure your lathe is stable.

- Align tools properly. Position tools to avoid movement.

- Clean work area. Remove debris before starting.

Tools Required for Precision Leveling

List of tools commonly used for leveling metal lathes. Tips on choosing the right tools for efficient leveling.To perfectly level your metal lathe, you need the right tools. Think of it like assembling your favorite LEGO set. You don’t want to be missing any pieces, right? Here’s a handy list of tools that can help:

| Tool Name | Purpose |

|---|---|

| Leveling Feet | For adjusting the height |

| Precision Level | To check the leveling accuracy |

| Spirit Level | A simple yet effective leveling tool |

| Wrenches | For tightening screws and bolts |

Choosing the right tools is like picking the best flavor of ice cream. Go for quality, and you’ll save time and effort. Remember, a fine adjustment today can make your lathe sing tomorrow!

Step-by-Step Guide to Leveling a Metal Lathe

Preparing the workspace for leveling. Detailed instructions for leveling the lathe.First, clean your workspace. Remove any clutter that might trip you up, or worse, steal your lunch! Next, gather your tools like a pro. You’ll need leveling feet, a wrench, and a spirit level—no, not the ghost kind. Start by placing the lathe on a flat surface. Use your spirit level on the bed of the lathe. Adjust the feet until the bubble sits right in the middle, just like a well-balanced pancake.

| Steps | Tools Needed |

|---|---|

| 1. Clean the workspace | None |

| 2. Gather tools | Leveling feet, wrench, spirit level |

| 3. Place the lathe correctly | None |

| 4. Check with spirit level | Spirit level |

| 5. Adjust the feet | Wrench |

After leveling, check it again. It’s like double-checking your math homework; no one wants a *wrong answer* here! Happy leveling!

Common Issues in Lathe Leveling and Their Solutions

Identification of common leveling problems. Troubleshooting tips and solutions for each issue.Leveling a lathe can be tricky. Some common problems can affect precision. These issues include uneven surfaces and machinery shifts during use. Here are ways to troubleshoot:

- Problem: Uneven base surface. Solution: Use shims to level the lathe.

- Problem: Vibration during operation. Solution: Ensure all parts are tightly secured.

- Problem: Incorrect adjustments. Solution: Regularly check and re-adjust level using a precision level.

By identifying and solving these issues, you can keep your lathe working well. It’s all about making it just right for amazing results!

What are some common lathe leveling problems?

Common problems include uneven surfaces, vibrations, and misaligned parts. Each can affect the quality of your work.

How can I troubleshoot these issues?

- Keep the lathe on a stable surface.

- Secure all components tightly.

- Adjust regularly for precision.

Maintaining Lathe Precision Over Time

Regular maintenance practices to ensure lasting precision. How environmental factors can affect lathe performance.Regular care keeps your lathe working well for years. Simple tasks like cleaning and lubricating parts can make a big difference. Check the bed and ways for wear and tear. Keep your workspace free from dust and moisture. Environmental factors, like temperature and humidity, can affect precision. Even slight changes can make a difference in metal lathe parts. Remember, a little attention goes a long way!

How can I keep my lathe working well?

Regular cleaning and lubrication help maintain precision. Ensure your workspace is dry and clean to avoid damage.

Check for wear on the lathe parts often.

Quick Tips

- Clean parts regularly.

- Lubricate moving parts.

- Keep the area clean and dry.

- Inspect for wear frequently.

Upgrading Metal Lathe Parts for Enhanced Precision

Recommended upgrades for better precision and efficiency. Impact of highquality parts on machining results.Upgrading parts of a metal lathe can boost its accuracy and speed. With better parts, you can make smoother cuts and create more detailed designs. Here are some recommended upgrades:

- High-Quality Tool Holders

- Precision Ground Bed Ways

- Improved Ball Screws

- Advanced Control Systems

Using high-quality parts can greatly affect machining outcomes. They lead to less wear and tear, resulting in more reliable tools. This upgrade can mean better performance and less time fixing problems.

What parts should I upgrade for better precision?

Focus on tool holders, bed ways, and ball screws for the best results. These parts help the lathe stay in shape and work smoothly.

Comparative Analysis of Different Metal Lathe Models

Feature comparison of popular metal lathe models. Suitability of each model for precision machining tasks.Choosing the right metal lathe can be tricky. Different models offer various features. Here’s a quick look:

- Model A: Great for beginners. Simple and easy to use.

- Model B: Precise and reliable. Perfect for professionals.

- Model C: Versatile with advanced features. Good for complex tasks.

Model A is best for small projects. Model B works well for precision machining. Model C can handle various jobs with ease. Each model suits different needs. Pick one that matches your project goals.

What should I consider when choosing a metal lathe?

The most important factors are features, size, and price. Consider your experience level and project needs when making your choice.

Resources for Further Learning on Lathe Precision and Parts

Recommended books, websites, and courses. Community forums and groups for ongoing support and advice.Learning about lathe precision and parts can be fun and rewarding! For starters, several books cover everything from basics to advanced techniques. Websites like Instructables and YouTube offer great tutorials. You can even take online courses from platforms like Udemy. Also, don’t forget to join community forums like Reddit or Facebook groups where you can ask questions and share laughs with fellow lathe enthusiasts. Remember, it’s not just about the parts; it’s about the community!

| Resource Type | Recommendations |

|---|---|

| Books | “The Complete Guide to Precision Machining” |

| Websites | Instructables, YouTube |

| Online Courses | Udemy, Coursera |

| Forums | Reddit, Facebook Groups |

Conclusion

In summary, lathe precision leveling is crucial for making accurate metal parts. You need to ensure your lathe is level for the best results. Check your equipment often and make adjustments as needed. We encourage you to explore more about this topic and practice your skills. This will help you become a better machinist and create high-quality parts.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Parts:Sure! Lathe precision leveling is important because it helps machines work better. If a lathe is not level, it can make bad shapes. You can check the level using tools like a bubble level. Metal lathe parts are the pieces of the machine that help it move and cut metal. When all parts are working well, your projects will turn out just right!

Sure! Please provide the question you’d like me to answer.

What Techniques Are Commonly Used To Achieve Precision Leveling On A Metal Lathe?To achieve precision leveling on a metal lathe, we can use a few important techniques. First, we check if the lathe is on a flat surface. Next, we can use a level tool to see if it’s straight. We might also adjust the feet or legs of the lathe to make it level. Finally, we can double-check everything to be sure it’s perfect before starting work!

How Do The Tolerances Of Lathe Parts Affect The Overall Accuracy And Precision Of The Machining Process?Tolerances are the tiny differences allowed in the size of lathe parts. When we set tighter tolerances, the parts fit together better. This helps the machine work more accurately and precisely. If the tolerances are too loose, the parts might not fit right, causing errors in the final product. So, good tolerances help ensure everything works well and looks good!

What Tools And Equipment Are Necessary For Properly Leveling A Metal Lathe?To level a metal lathe, you need a few simple tools. First, get a bubble level. This tool helps us see if the lathe is flat. Next, have some shims ready. Shims are small pieces to help raise or lower parts of the lathe. Lastly, use a wrench to tighten screws and bolts. These tools will help keep everything balanced!

How Can Improper Leveling Of A Lathe Lead To Issues In Machining And Part Quality?If a lathe is not level, it can cause problems when we use it. The parts we make might not be shaped correctly. This can lead to uneven surfaces or wrong measurements. When we don’t get these right, the finished piece can be weak or useless. So, it’s important to make sure the lathe is level before we start.

What Are The Signs That Indicate A Metal Lathe May Need To Be Re-Leveled To Maintain Precision?If your metal lathe starts making strange noises, it might need re-leveling. You may notice that your pieces aren’t cutting evenly. Check if the machine feels wobbly or unstable. If it shakes when you use it, that’s another sign. Finally, if you see gaps or uneven parts in your work, it’s time to re-level.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Lathe precision leveling is important because it helps machines work better. If a lathe is not level, it can make bad shapes. You can check the level using tools like a bubble level. Metal lathe parts are the pieces of the machine that help it move and cut metal. When all parts are working well, your projects will turn out just right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Techniques Are Commonly Used To Achieve Precision Leveling On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling on a metal lathe, we can use a few important techniques. First, we check if the lathe is on a flat surface. Next, we can use a level tool to see if it’s straight. We might also adjust the feet or legs of the lathe to make it level. Finally, we can double-check everything to be sure it’s perfect before starting work!”}},{“@type”: “Question”,”name”: “How Do The Tolerances Of Lathe Parts Affect The Overall Accuracy And Precision Of The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Tolerances are the tiny differences allowed in the size of lathe parts. When we set tighter tolerances, the parts fit together better. This helps the machine work more accurately and precisely. If the tolerances are too loose, the parts might not fit right, causing errors in the final product. So, good tolerances help ensure everything works well and looks good!”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Necessary For Properly Leveling A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you need a few simple tools. First, get a bubble level. This tool helps us see if the lathe is flat. Next, have some shims ready. Shims are small pieces to help raise or lower parts of the lathe. Lastly, use a wrench to tighten screws and bolts. These tools will help keep everything balanced!”}},{“@type”: “Question”,”name”: “How Can Improper Leveling Of A Lathe Lead To Issues In Machining And Part Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe is not level, it can cause problems when we use it. The parts we make might not be shaped correctly. This can lead to uneven surfaces or wrong measurements. When we don’t get these right, the finished piece can be weak or useless. So, it’s important to make sure the lathe is level before we start.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Metal Lathe May Need To Be Re-Leveled To Maintain Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe starts making strange noises, it might need re-leveling. You may notice that your pieces aren’t cutting evenly. Check if the machine feels wobbly or unstable. If it shakes when you use it, that’s another sign. Finally, if you see gaps or uneven parts in your work, it’s time to re-level.”}}]}