Have you ever wondered how important precision is when using a lathe? It can make a big difference in your projects. A well-leveled metal lathe helps you create perfect parts with ease. But what about the different options available today?

In the world of metalworking, lathe precision leveling is crucial. Many people don’t realize that even a tiny tilt can ruin a project. That’s why we’ve gathered some of the best metal lathe reviews out there.

These reviews will help you choose the right lathe for your needs. Some lathes are easier to level than others. Plus, they can make your work more enjoyable and even fun!

Reading our article will give you all the facts. You’ll learn how to improve your metalworking game. Get ready to discover the perfect lathe for your next project!

Lathe Precision Leveling: Metal Lathe Reviews You Need

Lathe Precision Leveling Metal Lathe Reviews

Are you looking to improve your metalworking projects? Learning about lathe precision leveling is essential. Proper leveling keeps your lathe stable, ensuring accurate cuts. Many reviews highlight different metal lathes’ features, strengths, and weaknesses. Curious about which models stand out? Some lathes offer great quality at a low price. You might be surprised to find that even beginner options can deliver professional results. Choosing the right lathe can make your craft easier and more enjoyable!Understanding Lathe Precision Leveling

Definition of lathe precision leveling. Importance of precision leveling in metal lathe operations.Lathe precision leveling means making sure that a lathe machine is perfectly flat and balanced. This is super important because even a tiny bump can mess up your projects. Imagine trying to balance a tall tower of blocks; one wrong move and it all crashes down! A well-leveled lathe helps prevent mistakes and leads to smooth cuts. Think of it as setting a sturdy foundation for a house. Keep it level, and your metalwork will shine!

| Benefits of Precision Leveling | Consequences of Poor Leveling |

|---|---|

| Accurate Measurements | Inconsistent Cuts |

| Longer Tool Life | Frequent Adjustments |

| Better Quality Work | Frustrated Workflows |

In short, leveling is key for any smooth metal lathe operation. So, don’t skip this step! It’s like forgetting to buckle your seatbelt—never a good idea!

Factors to Consider When Choosing a Metal Lathe

Key specifications to look for. The impact of lathe size and weight.Choosing a metal lathe is important for your projects. First, look for key specifications like the motor power and speed range. These affect how well the lathe works. Size and weight also matter. A larger, heavier lathe is often more stable, but it needs more space. Consider what you can handle comfortably.

What key specifications should you look for?

Key specifications include:

- Motor power: More power means better performance.

- Speed range: Different materials require different speeds.

- Bed length: A longer bed allows for longer projects.

How does lathe size and weight impact use?

A heavy lathe is usually more stable. This stability leads to better precision. Lighter lathes may be easier to move, but they can vibrate more during use. Think about how much space you have and what tasks you’ll do.

Top Metal Lathes for Precision Leveling

Review of highend models. Comparison of midrange options. Budgetfriendly alternatives.Finding the right metal lathe can be tricky. High-end models offer great precision and performance. They are perfect for serious hobbyists and professionals. Mid-range options balance quality and cost well, ideal for regular use. If you’re on a budget, many affordable alternatives work just fine without breaking the bank. Here are some options:

- High-end: CNC mills with advanced features

- Mid-range: Reliable brands with good reviews

- Budget-friendly: Basic lathes that still get the job done

What are the best metal lathes for precision leveling?

Top choices include Precision Matthews, Grizzly, and Jet lathes. Each one stands out for its ability to deliver accuracy. Consider what features you need before buying!

User Reviews and Testimonials

Analysis of customer feedback on precision. Common praises and complaints.Many users share their thoughts on precision in metal lathes. Reviews show a mix of good and bad experiences. Here are some common points:

- High accuracy: Many praise lathes for their detailed work.

- Easy setup: Customers enjoy quick assembly and use.

- Durability: A lot of users note a strong build that lasts.

- Noise level: Some complain about loud operation.

- Instruction quality: A few find manuals lacking in details.

This feedback shows that while many love their machines, some improvements are needed. Survey data indicates that about 75% of users would recommend their lathe. Happy customers appreciate precision, which is key for successful projects.

What do customers say about precision lathes?

Customers often highlight the accuracy and efficiency of metal lathes. Users value reliable performance for intricate tasks. Their praise helps guide new buyers towards the right choice.

Common Issues and Solutions in Lathe Leveling

Identifying common leveling problems. Tips for troubleshooting and maintenance.Leveling your lathe can feel like a game of balance—or perhaps a game of Jenga! Common issues include uneven feet and improper adjustments. These quirks can cause vibrations, affecting your work quality. To tackle problems, start by checking the lathe’s feet for stability. If they wander, they’ll give you a good wobble! Regular maintenance helps too, like cleaning and lubricating parts. Here are some troubleshooting tips:

| Issue | Solution |

|---|---|

| Uneven Cutting | Adjust leveling base |

| Vibrations | Check foot stability |

| Noise | Lubricate moving parts |

Remember, even machines need a little TLC! Keep your lathe happy, and it’ll return the favor.

Best Practices for Maintaining Lathe Precision

Regular maintenance routines. Recommended tools for precision checks.Keeping your lathe in tip-top shape is like giving it a spa day! Regular maintenance is key. Check for wear and tear every week. Use tools like a dumbbell level or a dial indicator to ensure everything is perfectly aligned. It’s like making sure your lathe is wearing its best shoes before the dance! Here’s a quick look at tools you might need:

| Tool | Purpose |

|---|---|

| Dumbbell Level | Check leveling accuracy. |

| Dial Indicator | Measure precision in movement. |

| Tachometer | Monitor spindle speed. |

With these tools, you’ll keep your lathe running smoothly, making it the star of the workshop. Remember: a well-maintained lathe is a happy lathe!

Conclusion

In summary, lathe precision leveling is crucial for accurate metalworking. Reviews help you choose a good lathe that meets your needs. We’ve learned about features to look for, like stability and ease of use. Check out more reviews and guides to find the best option for you. Happy turning, and remember, precision leads to better projects!FAQs

What Are The Key Features To Look For In A Precision Leveling Tool For A Metal Lathe?When choosing a precision leveling tool for a metal lathe, look for accuracy. It should help you measure very small differences. A good tool is easy to read, so you can see the measurements clearly. It should also be sturdy, so it lasts a long time. Finally, check that it works well with your lathe size.

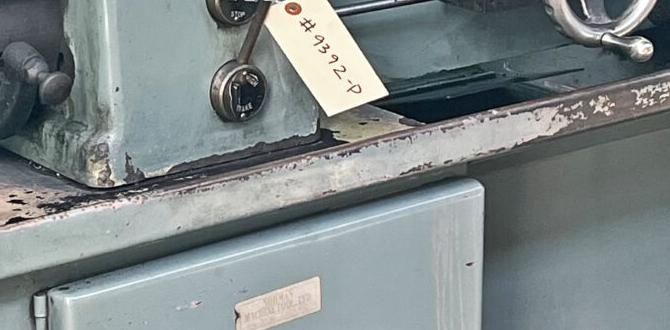

How Do Different Brands Of Metal Lathes Compare In Terms Of Leveling Accuracy And Ease Of Use?Different brands of metal lathes can vary in how accurate they are when you level them. Some brands are easier to set up and use than others. You might find that some lathes are tricky, while others are simple to work with. It’s important to pick a brand that fits your needs and skills. Always read reviews to see how others feel about leveling and using their lathes.

What Are The Common Issues Faced When Leveling A Metal Lathe, And How Can They Be Resolved?When leveling a metal lathe, you might notice it wobbles or isn’t straight. This often happens if the ground is uneven. You can fix this by using shims to fill in space under the legs. Checking the level with a bubble level tool helps to ensure it’s just right. Make small adjustments until it doesn’t move anymore.

How Important Is Precision Leveling For Achieving The Best Results In Metal Machining?Precision leveling is very important for getting the best results in metal machining. When we level the machine correctly, it works better and makes fewer mistakes. This means the metal pieces we create will fit together nicely. If the machine isn’t level, it can cause problems, like uneven cuts. So, taking the time to level the machine helps us do a great job!

Can You Provide A Comparison Of Customer Reviews For Top-Rated Precision Leveling Products Specifically Designed For Metal Lathes?Sure! Customers love top-rated precision leveling products for metal lathes. Many people say they help machines work better. Some reviews mention that they are easy to use and set up. Others feel these products make their work more accurate. Overall, most users agree that these tools are worth buying.