Have you ever thought about how important safety is when using a metal lathe? Proper lathe precision leveling can make all the difference. Imagine working on a project where your machine suddenly slips. It can be frustrating and dangerous!

Metal lathes are wonderful tools. They help people create amazing things from metal. But, to get the best results, you need to keep them level. Precision leveling ensures that your lathe works smoothly. Did you know that even a small tilt can affect your work?

Let’s dive into how to make your metal lathe safer and more precise. Learning about safety measures can protect you and help your projects shine. So, grab your toolbox and let’s explore the world of lathe precision leveling together!

Lathe Precision Leveling: Ensuring Metal Lathe Safety

Lathe Precision Leveling and Metal Lathe Safety

Understanding lathe precision leveling is crucial for effective machining. A well-leveled lathe leads to accurate cuts and improved finishes. Did you know that even a tiny misalignment can cause big problems? Safety should always come first. Use proper personal protective equipment, like gloves and goggles, to stay safe while operating a metal lathe. By following basic safety tips and keeping your equipment leveled, you can enjoy a smoother and safer machining experience.Understanding Lathe Precision Leveling

Importance of precision leveling in metalworking. Key factors affecting lathe performance and accuracy.Precision leveling is key in metalworking. It ensures your lathe works properly and produces great results. Imagine trying to build a house on a wobbly foundation; it’s not going to end well! Key factors like alignment, vibration control, and weight distribution affect your lathe’s performance. Even a small tilt can lead to errors. So, keep your lathe as straight as a ruler to achieve perfect cuts every time!

| Key Factor | Impact |

|---|---|

| Alignment | Ensures accuracy in cuts |

| Vibration Control | Reduces errors and enhances smoothness |

| Weight Distribution | Prevents tipping and uneven cuts |

Tools Required for Levelling a Metal Lathe

Essential tools: levels, shims, and supports. Recommended brands and models for accuracy.For leveling a metal lathe, you need a few important tools. These include levels, shims, and supports. Levels help you check if the lathe is straight. Shims fill gaps to get everything in line. Supports hold the lathe steady. Here are some recommended tools:

- Bubble Level – Starrett

- Metal Shims – McMaster-Carr

- Support Stands – JET

Using these tools will help you achieve precision leveling for safety and better performance.

What tools do you need to level a metal lathe?

You need tools like a level, shims, and supports to ensure your lathe is properly aligned. Levels measure flatness, shims adjust height, and supports provide stability.

Step-by-Step Guide to Leveling Your Lathe

Preparation: initial assessment and setup. Detailed leveling process: techniques and tips.First, check your work area. Is your lathe on a stable surface? Ensure it’s not teetering like a seesaw at a playground! Next, gather your tools: a level, wrenches, and a friend (because every great adventure needs a buddy!).

Now, to level your lathe, follow these steps:

| Step | Action |

|---|---|

| 1 | Place the level on the lathe bed. |

| 2 | Adjust the feet until the bubble is centered. |

| 3 | Recheck periodically while tightening. |

For a smooth finish, level in both directions. Remember, it takes practice—so don’t get frustrated! A tiny wobble can turn your project into a wobbly wonder. Always prioritize lathe safety while you work for fun and success!

Common Mistakes to Avoid When Leveling a Lathe

Typical errors that affect precision. How to recognize and correct these mistakes.Leveling a lathe is essential for precision, but it’s easy to make mistakes. One common error is not checking the ground surface where the lathe sits. If it’s uneven, your work will be too—like trying to hang a picture on a wobbly wall! Always use a level to ensure your lathe is straight. Another mistake is skipping the lock on the leveling feet. This can cause shifts while you work, turning your masterpiece into a very expensive paperweight! If you notice vibrations or uneven cuts, check those settings right away.

| Error | How to Recognize | Correction |

|---|---|---|

| Uneven surface | Diagram shows workspace rocking. | Use leveling wedges. |

| Unlocked leveling feet | Lathe shakes during operation. | Lock the feet tightly. |

Enhancing Safety While Operating a Metal Lathe

Essential safety gear and equipment. Best practices for a safe working environment.When using a metal lathe, safety should be your top priority. Wearing the right safety gear is crucial. Essential items include safety glasses, gloves, and ear protection. These help protect you from flying debris and loud noises.

- Always keep your workspace tidy to avoid accidents.

- Check all equipment before starting work.

- Never wear loose clothing or jewelry that could get caught.

- Create a clear space around the lathe and avoid distractions.

By following these steps, you’ll make your work environment safer and more enjoyable.

What is the best safety gear for operating a metal lathe?

Using safety gear is essential for protecting yourself. Some of the best gear includes safety goggles, ear protection, and work gloves. This gear helps prevent injuries while using a lathe.

Routine Maintenance Tips for Lathe Users

Importance of regular maintenance for safety and performance. Checklist of maintenance tasks to ensure longevity.Taking care of your lathe is key for safety and great performance. Regular maintenance keeps your machine running smoothly. When you clean and check it often, you help it last longer. Here’s a simple checklist to follow:

- Clean dust and chips after use.

- Check all belts and gears for wear.

- Oil moving parts as needed.

- Inspect electrical connections for damage.

Doing these tasks can prevent big problems and keep you safe while working.

Why is regular maintenance important?

Regular maintenance increases the lifespan of your lathe. It helps avoid accidents. A well-maintained lathe performs better, giving you precise cuts.

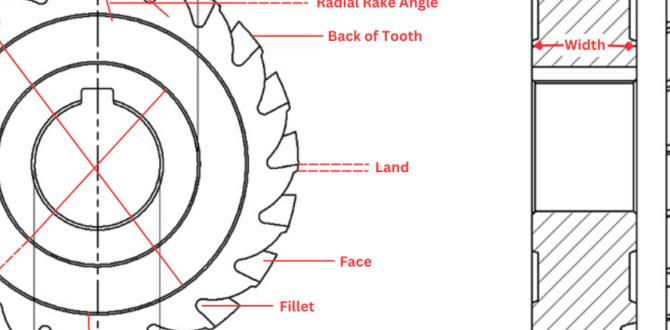

Advanced Techniques for Precision Machining

Techniques to further enhance lathe accuracy. Tips from industry experts and experienced machinists.To boost lathe accuracy, try some expert techniques. Level your lathe correctly. This helps with precision. Use quality cutting tools for better results. Keep tools sharp and clean. Regular maintenance is key. Here are some practical tips:

- Calibrate the machine often.

- Check alignment before starting.

- Optimize feed rates for different materials.

Learn from the pros. They say, “A well-tuned lathe makes magic happen.” This is true for quality work.

How can you enhance lathe precision?

Your lathe’s precision can be enhanced by ensuring proper alignment, regular calibration, and using sharp tools.

Resources for Further Learning and Troubleshooting

Books, courses, and online forums for lathe operators. Contacting professionals for help and advice.Learning about lathe operation can be fun! Many great resources can help. Consider these:

- Books on lathe techniques and safety.

- Online courses that show you how to work a lathe.

- Forums where lathe operators share tips and advice.

If you need more help, don’t hesitate to contact a local expert. They can provide friendly guidance and support. Remember, everyone starts somewhere—keep learning!

Where can I find helpful lathe resources?

Check out books, online courses, and forums for guidance. These resources can improve your skills and understanding of lathe operation.

Conclusion

In conclusion, lathe precision leveling is crucial for safe and accurate work. Always check your equipment and follow safety guidelines. Remember to wear proper gear and maintain a clean workspace. By practicing these tips, you can improve your skills and work safely. For more information, consider reading guides on lathe safety and maintenance. Let’s keep learning together!FAQs

What Are The Key Steps To Ensure Precise Leveling Of A Metal Lathe Before Operation?To level a metal lathe, you start by finding a flat surface. Use a level tool to check if the machine is straight. Adjust the legs of the lathe until it sits flat. Tighten everything once it is level. Finally, double-check with the level to make sure it’s perfect.

What Safety Precautions Should Be Taken When Setting Up And Leveling A Metal Lathe?When setting up a metal lathe, always wear safety glasses to protect your eyes. Make sure the area is clean and dry to prevent slipping. Check that all parts are tight and secure so nothing can fall off while you work. Never wear loose clothing or jewelry that could get caught in the machine. Finally, keep your hands and tools away from moving parts to stay safe.

How Does Improper Leveling Affect The Accuracy And Safety Of A Metal Lathe During Machining?If a metal lathe isn’t level, it can make mistakes when shaping metal. This means the pieces may not fit together right. It can also cause the machine to shake or move, which can make it unsafe. We need to keep it level to work safely and make good parts. Always check the level before using it!

What Tools And Instruments Are Recommended For Checking And Achieving Precision Leveling On A Metal Lathe?To check if a metal lathe is level, you can use a spirit level. It helps you see if the machine is straight. A dial indicator can also measure small movements to ensure it is just right. You might also want a precision straightedge for another way to check the flatness. Remember, keeping everything level helps make better parts!

What Are The Common Hazards Associated With Improperly Leveled Metal Lathes, And How Can They Be Mitigated?If a metal lathe isn’t level, it can shake and cause mistakes. This might lead to accidents or broken parts. To stay safe, always check if the lathe is level before using it. You can use a level tool to help with this. Keeping the area around the lathe clean also helps prevent trips and falls.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Steps To Ensure Precise Leveling Of A Metal Lathe Before Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you start by finding a flat surface. Use a level tool to check if the machine is straight. Adjust the legs of the lathe until it sits flat. Tighten everything once it is level. Finally, double-check with the level to make sure it’s perfect.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Setting Up And Leveling A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up a metal lathe, always wear safety glasses to protect your eyes. Make sure the area is clean and dry to prevent slipping. Check that all parts are tight and secure so nothing can fall off while you work. Never wear loose clothing or jewelry that could get caught in the machine. Finally, keep your hands and tools away from moving parts to stay safe.”}},{“@type”: “Question”,”name”: “How Does Improper Leveling Affect The Accuracy And Safety Of A Metal Lathe During Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe isn’t level, it can make mistakes when shaping metal. This means the pieces may not fit together right. It can also cause the machine to shake or move, which can make it unsafe. We need to keep it level to work safely and make good parts. Always check the level before using it!”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Recommended For Checking And Achieving Precision Leveling On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a metal lathe is level, you can use a spirit level. It helps you see if the machine is straight. A dial indicator can also measure small movements to ensure it is just right. You might also want a precision straightedge for another way to check the flatness. Remember, keeping everything level helps make better parts!”}},{“@type”: “Question”,”name”: “What Are The Common Hazards Associated With Improperly Leveled Metal Lathes, And How Can They Be Mitigated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe isn’t level, it can shake and cause mistakes. This might lead to accidents or broken parts. To stay safe, always check if the lathe is level before using it. You can use a level tool to help with this. Keeping the area around the lathe clean also helps prevent trips and falls.”}}]}