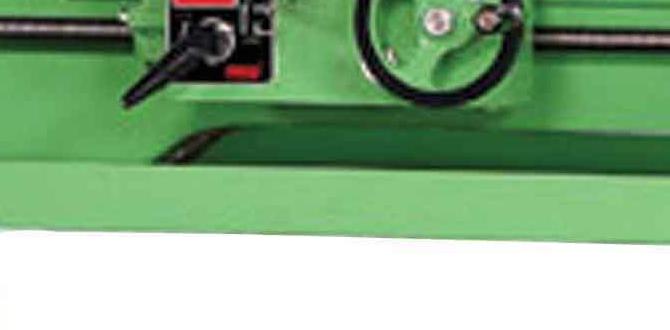

Have you ever watched a lathe spin? It’s fascinating! A lathe can shape metal in incredible ways.

But did you know that the secret to its magic lies in precision leveling? Properly setting up your metal lathe is key to getting great results.

Imagine your lathe wobbling during a project. That would lead to mistakes and waste time, right?

In this article, we will explore how to achieve perfect lathe precision leveling. We’ll share tips for setting up your lathe like a pro. Whether you’re a beginner or a skilled crafter, you’ll find useful ideas!

So, are you ready to make your metal projects better? Let’s dive in and discover the best ways to set up your lathe.

Lathe Precision Leveling: Essential Metal Lathe Setup Guide

Lathe Precision Leveling for Metal Lathe Setup

Setting up a metal lathe involves key steps for precision leveling. Proper leveling is crucial for achieving accurate cuts. Did you know that a warped lathe can lead to costly mistakes? To level your lathe, check the bed with a level tool and adjust the feet accordingly. A well-leveled lathe enhances performance and prolongs the machine’s life. Remember, small adjustments can lead to big improvements!Understanding Lathe Precision Leveling

Importance of precision leveling in metalwork. How leveling impacts machining accuracy and performance.Precision leveling is crucial for metalwork. If your lathe isn’t level, parts won’t fit together well. This can lead to mistakes and wasted materials.

Leveling affects machining accuracy and performance. A well-leveled lathe creates better products. Here are some important points to know:

- Reduces wear on the machine.

- Improves cutting quality.

- Makes setups easier and faster.

Remember, a small error in leveling can mean a big problem in your finished work!

Why Does Leveling Matter in Metalwork?

Leveling ensures accuracy and efficiency in machining tasks. An angle that is off can create mistakes in the parts you make.

Essential Tools for Lathe Leveling

Musthave tools for precise leveling. Recommendations for digital vs. analog level indicators.To level your lathe accurately, you need the right tools. Here are some must-have items:

- A digital level is great for precise measurements.

- An analog level is simple and easy to use.

- Calipers help you check measurements closely.

- A straight edge ensures everything is aligned.

Digital levels offer exact readings. They often display numbers on a screen. Analog levels can be more affordable and don’t need batteries. Pick what works best for you!

What tools do I need for lathe leveling?

You need a digital or analog level, calipers, and a straight edge for lathe leveling. These tools help you ensure everything is set up correctly for great results.

Step-by-Step Guide to Leveling Your Metal Lathe

Initial preparation before leveling. Detailed steps to achieve precise leveling. Common mistakes to avoid during setup.Before you begin leveling your metal lathe, you need to prepare properly. Check that your workspace is clean. Make sure the lathe is on a solid surface. Use a reliable level for accuracy. Follow these steps for precise leveling:

- Place the level on the bed of the lathe.

- Adjust the feet of the lathe until the bubble is centered.

- Repeat the process at different points on the lathe.

Avoid these common mistakes:

- Don’t rush the leveling process.

- Avoid using an unsteady level.

- Make sure the surface is completely flat.

What should you check before leveling a metal lathe?

Ensure the lathe is on a stable surface, check for clean work conditions, and use a quality level.Factors Affecting Lathe Precision Leveling

Impact of the workplace environment on leveling. How temperature and moisture can affect metal lathe performance.Several things can change how well a lathe levels. First, the workplace environment matters. Temperature and moisture can impact metal lathe performance. For instance, high heat can cause metal to expand. This expansion can lead to uneven cuts. Similarly, moisture can lead to rust, making precise work hard.

How does temperature affect metal lathe performance?

Temperature changes can lead to metal expansion or contraction, affecting accuracy.Additional Factors

- High temperatures can warp parts.

- Cold air can slow down operations.

- Moisture can cause rust build-up.

Maintaining Lathe Precision Over Time

Routine checks to ensure ongoing precision. Best practices for maintaining a leveled lathe setup.Keeping your lathe working well is important for good projects. Regular checks help catch problems early. Routine checks include looking at the levels and making sure they are just right. Also, clean the lathe to avoid dust build-up. Following the best practices can improve precision. Here are some tips:

- Check levels often.

- Clean tools after each use.

- Adjust settings according to the material.

- Lubricate moving parts regularly.

With these steps, your lathe can stay precise for a long time!

How often should I check my lathe for precision?

It’s best to check your lathe monthly for precision. A quick check after big projects is also good. Regular maintenance helps keep everything running smoothly!

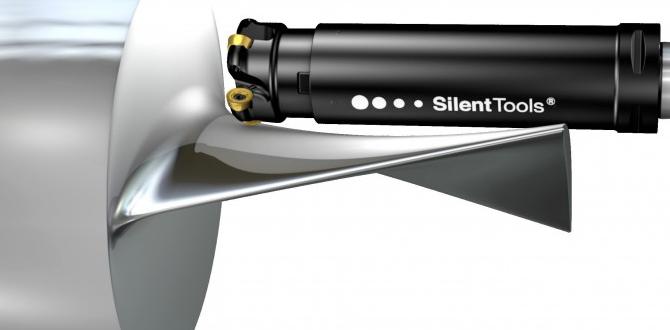

Advanced Techniques for Precision Lathe Leveling

Techniques for experienced machinists. Utilizing laser leveling and advanced measurement tools.For skilled machinists, mastering precision lathe leveling is key. One advanced technique is using laser leveling tools. These gadgets use light to show tiny differences in height. Imagine using a magic beam to make things level! Another method involves measurement tools, like micrometers and dial gauges. These pinpoint errors that the eye might miss. Recent studies show that proper leveling can improve machining accuracy by up to 30%! Why not level up your skills?

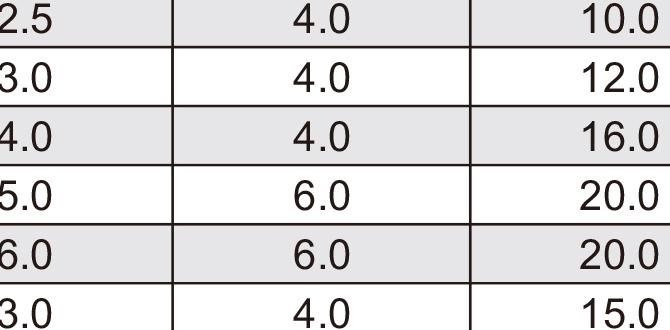

| Technique | Advantage |

|---|---|

| Laser Leveling | Quick and precise alignment |

| Measurement Tools | Detects tiny errors |

Addressing Common Lathe Leveling Issues

Troubleshooting persistent leveling problems. Solutions for improving lathe setup stability.Persistent leveling problems can make using a lathe difficult. First, check for convenience. Is the floor even? An uneven floor can cause instability. Next, look at your lathe’s feet. Are they all touching the ground? If not, try using small shims to stabilize it.

Here are some tips to improve stability:

- Level the lathe on a flat surface.

- Regularly check the alignment.

- Use a spirit level for accuracy.

What do I do if my lathe keeps moving?

If your lathe keeps moving, check the leveling. It’s important for stable operation. You might need to adjust its feet or add support to the floor.Conclusion

In summary, lathe precision leveling is crucial for a successful metal lathe setup. It ensures accurate cuts and smooth operations. Remember to check your lathe’s level regularly for the best results. We encourage you to practice these leveling techniques and explore more resources for further learning. With attention to detail, you can improve your metalworking skills effectively!FAQs

What Are The Key Steps To Achieve Precision Leveling On A Metal Lathe, And Why Is It Important For Accurate Machining?To achieve precision leveling on a metal lathe, first, make sure the lathe is on a sturdy surface. Next, use a level tool to check if the lathe is flat. If it’s not, adjust the feet of the lathe until it is level. Finally, secure everything tight so it doesn’t move. Leveling is important because it helps the lathe cut accurately, which makes your parts fit better.

How Can You Determine If Your Lathe Is Properly Leveled Before Starting A Machining Operation?To check if your lathe is level, first, you need a small level tool. Place the level on the bed of the lathe. If the bubble in the level is centered, your lathe is level. If not, you can adjust the feet of the lathe until it is level. Always make sure it’s level before starting your work.

What Tools Or Instruments Are Recommended For Checking The Level Of A Metal Lathe?To check if a metal lathe is level, you can use a bubble level. This tool has a small glass tube with a bubble inside. You place the level on the lathe bed. If the bubble is in the middle, your lathe is level. You can also use a machinist’s level for more precision.

How Does The Floor Surface And Machine Location Affect The Leveling Process Of A Metal Lathe?The floor surface under the metal lathe needs to be flat and strong. If the floor is uneven, it can make the lathe wobbly. You should also place the lathe in a safe spot, away from heavy vibrations or bumps. This helps the machine work better and stay level. Keeping everything steady makes sure your lathe can cut metal smoothly.

What Common Mistakes Should Be Avoided During The Precision Leveling Setup Of A Metal Lathe?When setting up a metal lathe, avoid a few common mistakes. First, make sure the lathe is on a flat surface. If it’s not level, it can make bad cuts. Second, check that all the feet of the lathe touch the ground evenly. If some are off, the lathe can wobble. Lastly, don’t forget to double-check your measurements. Small errors can cause big problems later.