Have you ever wondered how precision is key in metalworking? Imagine making a tiny mistake while crafting a part. That could ruin your whole project! This is where lathe precision leveling comes into play.

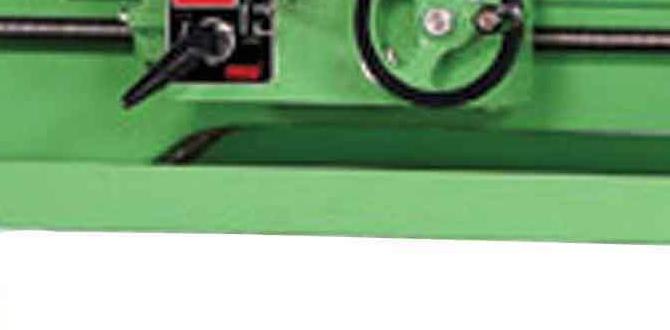

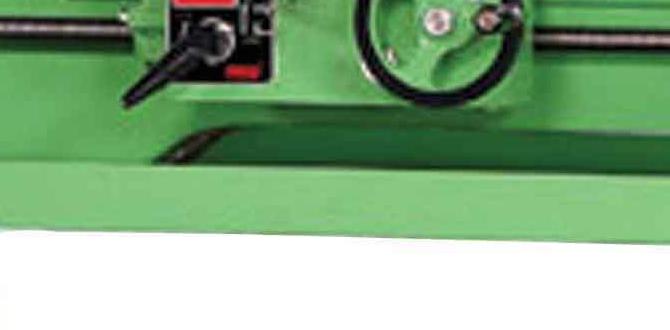

A lathe is a powerful machine used to shape metal. The tailstock is a vital part of it. It helps hold the workpiece steady. If the tailstock is not leveled correctly, you can face many problems. Your work can become uneven, leading to poor results.

Funny enough, even small adjustments can make a big difference. Think about setting up a game of marbles. If one is out of place, the whole game changes. In the same way, leveling your lathe affects your entire metalworking project.

Join us as we explore how to achieve perfect precision with your lathe’s tailstock. You’ll learn tips and tricks to get it just right, making your projects shine!

Lathe Precision Leveling: Metal Lathe Tailstock Setup Guide

Lathe Precision Leveling: Metal Lathe Tailstock

Achieving perfect precision on a metal lathe is vital. The tailstock plays a big role in this process. Proper leveling of the tailstock prevents inaccuracies that can ruin projects. Did you know that even a slight misalignment can lead to poor cuts? When you adjust your tailstock, think about how its stability impacts your entire setup. This attention to detail ensures your lathes work smoothly, making every project easier and more enjoyable!Understanding Lathe Precision

Definition of lathe precision. Importance of precision in metalworking.Lathe precision means being super accurate when working with a lathe machine. Think of it as making a cake: if you measure the flour wrong, the cake might collapse! In metalworking, precision is key. It helps make parts fit together perfectly, ensuring everything works smoothly. Without precision, even a tiny mistake can cause big problems! So, let’s keep our tools sharp and our eyes on the prize!

| Benefit of Precision | Description |

|---|---|

| Better Fit | Parts join together perfectly. |

| Smoother Operation | Machines run without hiccups. |

| Less Waste | Fewer mistakes mean less scrap metal! |

Signs Your Tailstock Needs Leveling

Common inaccuracies when machining. Consequences of an unlevel tailstock.Have you ever noticed that your lathe isn’t cutting straight? You might have an unlevel tailstock. This can lead to some common issues. Your workpiece might wobble or have uneven edges. In worse cases, it can even ruin the entire project. That’s like baking a cake and forgetting the sugar! Here’s a quick look at what can go wrong:

| Inaccuracy | Consequence |

|---|---|

| Wobbling Workpieces | Inconsistent cuts |

| Uneven Edges | Possible material waste |

| Rough Finish | Unprofessional look |

Don’t let a little tilt turn your dreams into a mess. Keep an eye on that tailstock and level it often. Your projects will thank you with smooth cuts and happy finishes!

Tools and Materials for Tailstock Leveling

Essential tools for leveling. Recommended materials for adjustments.Setting up your tailstock doesn’t have to be like solving a Rubik’s cube. You need the right tools and materials to make it smooth sailing. Essential tools include a level, which helps ensure everything is straight and true. A trusty ruler or caliper helps with precise measurements. For adjustments, try some shims or pads to fill in gaps. A simple combination of tools can ensure your lathe works well without throwing a tantrum!

| Tools | Materials |

|---|---|

| Level | Shims |

| Ruler/Caliper | Felt Pads |

| Wrench | Plastic Spacers |

Step-by-Step Guide to Leveling Your Lathe Tailstock

Initial setup and preparation. Detailed leveling procedures. Tips for finetuning alignment.Start by preparing your workspace. Make sure the lathe is clean and on a sturdy surface. Use a level tool to check if the lathe is flat. Next, follow these steps to position the tailstock:

- Loosen the tailstock locking knob.

- Align the tailstock with the spindle.

- Use a dial indicator to measure the alignment.

- Adjust the tailstock so that it lines up correctly.

For fine-tuning, keep these tips in mind:

- Check alignment after making adjustments.

- Make small changes to avoid over-correcting.

- Regularly clean and maintain the lathe to ensure accuracy.

How do you level a lathe tailstock?

Leveling a lathe tailstock requires aligning it with the spindle using a dial indicator. Start by ensuring the lathe is stable and level before making any adjustments.

Testing Precision After Leveling

Methods to verify tailstock accuracy. Troubleshooting common issues.To check your tailstock’s accuracy, you can use a few cool methods. First, try the dial indicator. It helps you see if the tailstock is perfectly aligned. If you notice your workpieces aren’t straight, don’t panic. Something’s likely just off. Check for uneven surfaces or sticky parts. Use a level to see if it’s sitting flat, too! Don’t let this become a “tail monster” going out of control. Just a little fix usually solves the problem.

| Method | Description |

|---|---|

| Dial Indicator | Measures alignment accurately. |

| Visual Inspection | Look for uneven surfaces or misalignment. |

| Level Check | Ensure the tailstock is on a flat surface. |

Maintaining Lathe Precision Over Time

Best practices for regular maintenance. How to periodically check tailstock alignment.Keeping your lathe in top shape helps you work better. Regular maintenance is key for great results. Here are some best practices:

- Always keep it clean. Remove dust and chips after every use.

- Check oil levels often. Good oil keeps parts moving smoothly.

- Tighten bolts and screws regularly to avoid loose parts.

To check tailstock alignment, follow these steps:

- Use a dial indicator to measure alignment.

- Adjust the tailstock until it lines up correctly.

- Re-check alignment frequently to maintain accuracy.

Why is tailstock alignment important?

Tailstock alignment is critical for precision machining. A misaligned tailstock can cause errors in your work. This may lead to wasted material and time. So, checking it often helps you create better products!

Common Mistakes to Avoid During Leveling

Typical errors in the leveling process. How to correct mistakes effectively.Leveling your lathe may seem easy, but mistakes happen! One common error is not checking the surface beneath your lathe. If it’s uneven, your work will wobble like a two-legged chair. Another mistake is forgetting to use a level tool correctly. Make sure to double-check that bubble before you start. If you do notice an error, don’t panic! Simply adjust the leveling feet until everything sits snug and level. Remember, even the best tools need a little TLC.

| Error | Correction |

|---|---|

| Uneven surface | Use leveling pads or shims |

| Incorrect leveling tool use | Check your tool’s bubble twice |

With a little care, you can avoid these hiccups and keep your lathe working smoothly!

Advanced Techniques for Enhanced Precision

Innovative leveling methods. Integrating technology for precise adjustments.Want to level up your lathe game? Try some innovative leveling methods! Using digital tools can help you make precise adjustments with ease. Imagine turning knobs, and suddenly everything is level! It’s like magic, but with metal! You can even use laser guides or smartphone apps for great accuracy. It’s tech straight out of a sci-fi movie! Remember, being level helps avoid mistakes and keeps your projects on track. Here’s a quick look:

| Method | Description |

|---|---|

| Digital Level | Shows exact tilt for perfect leveling. |

| Laser Guide | Projects a straight line for easy alignment. |

| Smartphone App | Turns your phone into a leveling tool! |

Keep these tools handy, and you’ll always be on the level! And remember: leveling might not be the most exciting thing in the shop, but it sure beats a wobbly project!

Conclusion

In conclusion, proper lathe precision leveling is vital for accurate metalworking. A well-aligned tailstock improves precision and reduces errors. You can enhance your projects by checking your lathe regularly. Remember to practice and explore more resources on lathe setups. With time, you’ll gain skills that make your work easier and more enjoyable. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling, Specifically Focusing On The Metal Lathe Tailstock:To keep the tailstock level on a metal lathe, you need to adjust it carefully. Leveling helps make sure the workpiece turns evenly. If it’s not level, it can cause problems while cutting. You can use a level tool to check if it’s straight. Always take your time to set it up right!

Sure! Please provide the question you would like me to answer.

What Are The Key Steps To Achieve Accurate Precision Leveling Of A Metal Lathe Tailstock?To level a metal lathe tailstock accurately, follow these steps: First, check if the lathe is on a flat surface. Next, use a level tool to see how straight the tailstock is. If it’s not level, adjust the feet of the tailstock until it is straight. Then, double-check with the level to make sure it’s correct. Finally, secure everything so it stays in place when you work.

Why Is It Important To Level The Tailstock Of A Lathe, And How Does This Affect Machining Accuracy?Leveling the tailstock of a lathe is important because it helps make sure your work is straight. If the tailstock is not level, your piece can wobble or shape unevenly. This can make your work less accurate and lead to mistakes. By keeping the tailstock level, you get cleaner cuts and better results. This means your projects turn out just the way you want!

What Tools And Equipment Are Recommended For Checking And Adjusting The Level Of A Lathe Tailstock?To check and adjust the level of a lathe tailstock, you need a few tools. First, use a level. This tool makes sure things are straight and even. Next, you can use a ruler or caliper to get precise measurements. Finally, a wrench helps you tighten or loosen parts. With these tools, you can make your lathe tailstock work better!

How Can You Identify Signs Of Misalignment In The Tailstock, And What Are The Potential Consequences For Workpieces?You can spot misalignment in the tailstock by checking if the workpiece wobbles. Also, if you see uneven cuts or marks on the piece, that’s a sign too. Misalignment can cause the workpiece to be shaped incorrectly. This could lead to problems later when you fit parts together. Always make sure the tailstock is lined up right for better results.

What Techniques Can Be Employed To Make Minor Adjustments To The Tailstock Leveling After Initial Setup?To adjust the tailstock leveling, you can use a few simple methods. First, check if the tailstock has screws on the side. You can loosen these screws a little and shift the tailstock. Next, use a level tool to see if everything is straight. Finally, tighten the screws again after you make your changes. This will help keep the tailstock in the right position.