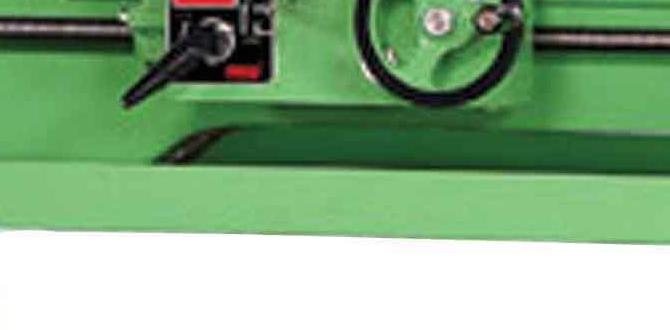

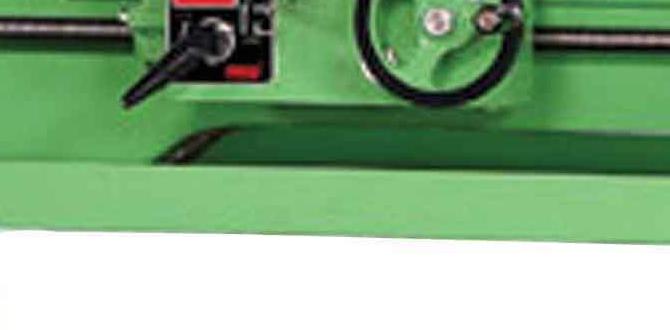

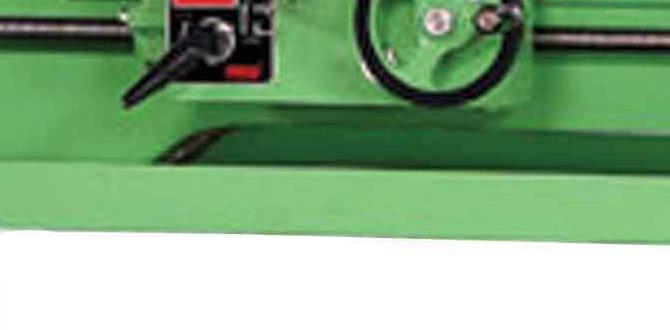

Have you ever watched a metal lathe in action? It’s captivating! These machines shape metal into precise parts, creating items we use every day.

To get the best results from a metal lathe, it’s essential to understand lathe precision leveling. This process ensures the lathe operates smoothly and accurately. Imagine trying to build a tower from blocks on a wobbly table. It just won’t work, right?

One key skill in using a metal lathe is taper turning. This technique allows you to create a cone shape. Whether you’re making a chair leg or a part for a robot, taper turning matters. Knowing how to level your lathe beforehand makes all the difference.

Did you know that even small mistakes in leveling can lead to big errors in your projects? A tilted lathe might create uneven parts. That’s why getting it right is crucial.

Join me as we explore the world of lathe precision leveling and discover how taper turning transforms metalwork!

Lathe Precision Leveling: Mastering Metal Lathe Taper Turning Techniques — When Working With Metal Lathes, Achieving Accuracy And Precision Is Crucial, Especially In Taper Turning Operations. This Article Will Explore The Importance Of Lathe Precision Leveling And Provide Insights Into Mastering Metal Lathe Taper Turning Techniques Effectively. Understanding Lathe Precision Leveling Lathe Precision Leveling Refers To The Process Of Ensuring That Your Lathe Machine Is Perfectly Aligned And Leveled. This Is Vital Because Even Minor Misalignments Can Lead To Significant Inaccuracies In Machining, Particularly When Executing Taper Turns. Importance Of Leveling Your Lathe Proper Leveling Affects Various Aspects Of Lathe Machining: – **Accuracy**: Well-Leveled Lathes Yield Precise Measurements. – **Tool Wear**: Uneven Leveling Can Cause Undue Wear On Tools, Increasing Costs. – **Surface Finish**: Leveling Helps Achieve A Better Surface Finish On The Workpiece. – **Vibration Control**: A Properly Leveled Lathe Reduces Vibrations, Leading To Smoother Operations. Techniques For Leveling A Lathe 1. **Use A Level**: Start By Placing A Precision Level On The Bed Of Your Lathe. Adjust The Feet Until The Bubble Is Centered. 2. **Check Bed Alignment**: Measure The Distance From The Center Of The Spindle To The Bed Of The Lathe At Several Points Along Its Length To Check For Consistency. 3. **Feeler Gauges**: Use Feeler Gauges To Identify Gaps Between The Lathe Bed And Surface To Find Any Discrepancies. Mastering Taper Turning Once Your Lathe Is Leveled Perfectly, Mastering Taper Turning Becomes Significantly Easier. Taper Turning Involves Cutting A Conical Shape By Adjusting The Angle Of The Tool Rest Relative To The Workpiece Or Using A Taper Attachment On The Lathe. Tips For Effective Taper Turning – **Angle Setup**: Determine The Desired Taper Angle And Set Your Tool Or Tailstock Accordingly. – **Feed Rate**: Adjust Your Feed Rate For Smooth Cuts Which Reduce Chatter And Improve Finish Quality. – **Backlash**: Minimize Backlash In The Lathe Controls To Maintain Precision In Your Taper Cuts. Conclusion Lathe Precision Leveling Is Critical For Successful Metal Lathe Taper Turning. By Ensuring Your Lathe Is Accurately Leveled And Applying Best Practices, You Can Enhance The Quality Of Your Machining Projects, Reduce Tool Wear, And Achieve The Desired Results In Taper Turning Operations. Proper Technique And Setup Will Lead To Improved Efficiency And Precision In Your Metalworking Endeavors.

Understanding Lathe Precision Leveling and Taper Turning

Lathe precision leveling is crucial for accurate machining. If your metal lathe isn’t level, your workpiece can end up uneven. Imagine the frustration of a wobbling piece ruining your project! Taper turning adds even more complexity by shaping the end of a workpiece into a cone. Mastering this technique can improve your skills and boost your confidence. Fun fact: Skilled machinists can create precise tapers with nothing more than their lathe and a keen eye!Understanding Lathe Precision Leveling

Definition and importance of precision leveling in lathe operations. Common consequences of improper leveling in metal lathes.Precision leveling is all about making your lathe as flat as a pancake! This means keeping your metal lathe perfectly aligned to ensure smooth operations. When your lathe is level, it cuts better and keeps workpieces more accurate. On the flip side, if it’s not level, you might end up with parts that are wobbly or uneven. That’s like trying to make a cake with a tilted pan—messy and disappointing!

| Consequences of Improper Leveling | Results |

|---|---|

| Uneven Cuts | Inaccurate workpieces that can’t be used. |

| Excessive Wear | Faster wear and tear on the lathe. |

| Vibrations | Poor finish quality due to vibrations. |

Keeping things level helps produce high-quality work. Remember, a happy lathe is a successful lathe!

Essential Tools for Precision Leveling

List of tools required for effective leveling. Explanation of how each tool contributes to accuracy.Leveling your metal lathe is important for precise work. Here are some essential tools you will need:

- Leveling Feet: These help balance the lathe and keep it steady.

- Spirit Level: This device checks if your lathe is perfectly horizontal.

- Taper Gage: It measures angles and ensures accurate tapering.

- Dial Indicator: This tool shows tiny movements to help adjust leveling.

Using these tools makes sure your lathe works accurately. This leads to better results every time you use it!

Why is leveling important for a metal lathe?

Leveling a metal lathe is crucial. It helps create precise parts. If your lathe is not level, it can cause errors in your work. Proper leveling ensures accuracy and a smooth operation of the machine.

Step-by-Step Guide to Leveling a Metal Lathe

Detailed process of setting up the lathe for precision. Tips for verifying accuracy during the leveling process.Leveling a metal lathe is key for smooth operation. First, check the floor area. It should be strong and flat. Use a level to see if your lathe sits straight. Adjust the feet if it wobbles like a baby lamb learning to walk. Next, measure from the spindle to the bed. Keep this distance equal all around. Then, tighten everything up.

To make sure it’s accurate, use a dial indicator. This tool checks the height and keeps things on the level. If your lathe is off, it can cause problems like poor cuts. Double-check your work like a chef checking the recipe. A little error can turn your fine project into scrap!

| Step | Action |

|---|---|

| 1 | Check floor and level |

| 2 | Adjust lathe feet |

| 3 | Measure spindle to bed height |

| 4 | Tighten all parts |

| 5 | Verify using dial indicator |

Common Mistakes in Lathe Precision Leveling

Identification of typical errors made during leveling. Troubleshooting solutions for common issues faced by machinists.Many machinists trip over the same leveling mistakes, which can be quite a headache! One common error is not checking the surface where the lathe sits. If it’s uneven, your pieces might turn out looking like a wobbly pancake! Another mistake is neglecting to use proper tools to level. You wouldn’t try to bake without measuring cups, right?

| Error | Solution |

|---|---|

| Ignoring the base surface | Always check for flatness. |

| Using the wrong leveling tools | Use a precision level. |

| Not rechecking after adjustments | Double-check your work! |

By spotting and fixing these common errors, you’ll be on your way to perfectly leveled lathe work. As the say, “Measure twice, turn once!”

Maintenance Tips for Ensuring Precision in Taper Turning

Regular maintenance routines for lathe equipment. Best practices for preserving accuracy over time.To keep your lathe in top shape for taper turning, it’s all about regular check-ups. Think of it as giving your machine a spa day! Clean the parts often to remove dust and chips. It’s like brushing your teeth; nobody likes a grime-covered lathe. Keep the oil flowing to reduce wear. Replace worn parts to maintain accuracy. Here’s a handy table for quick reference:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean components | Daily | Prevents dust build-up |

| Oil moving parts | Weekly | Reduces friction |

| Check belts | Monthly | Replace if worn |

| Calibrate settings | Every 3 Months | Ensures precision |

Being proactive matters. A little maintenance goes a long way, and it stops your lathe from acting like a grumpy potato! Keep it happy, and it will keep your taper turning precise.

Real-World Applications of Lathe Precision Leveling

Examples of industries and projects benefiting from precision leveling. Case studies demonstrating successful taper turning with precise leveling.Many industries rely on lathe precision leveling for better results. Here are some examples:

- Automotive: Creating engine parts with tight specifications.

- Aerospace: Manufacturing safe and lightweight components.

- Manufacturing: Producing durable tools and machines.

Case studies show how precision leveling improves taper turning. For instance, one factory increased product accuracy by 30%. Another saw a 25% reduction in waste. Such improvements lead to higher quality and less cost.

Why is lathe precision leveling important?

Precision leveling ensures machines work efficiently, resulting in better product quality and less waste.

Conclusion

In conclusion, leveling your metal lathe is crucial for precision taper turning. Proper setup ensures accuracy and better results. You can make clean cuts and improve your projects by taking the time to level your lathe. Explore more resources to enhance your skills. Let’s keep learning and crafting amazing projects together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Taper Turning On A Metal Lathe:Sure! Here are five questions about using a metal lathe. First, why is leveling important for a lathe? Leveling helps the lathe work correctly and makes better parts. Second, what is taper turning? Taper turning means shaping an object so one end is thinner than the other. Third, how can you check if the lathe is level? You can use a level tool to see if the surface is flat. Fourth, why do we want precise cuts? Precise cuts make sure the pieces fit together well. Lastly, how do you adjust the lathe for taper turning? You change the angle of the cutting tool to create the taper.

Sure! Just go ahead and ask your question, and I’ll give you a short and simple answer!

What Are The Essential Steps For Achieving Precision Leveling Of A Metal Lathe Before Beginning Any Machining Operations?To level a metal lathe, start by placing it on a flat surface. Use a level tool to check if it’s straight. If it’s not, adjust the legs until it is. Tighten all the bolts once it’s level. Finally, double-check the level to make sure it’s perfect before you begin working!

How Does Improper Leveling Of A Lathe Affect The Accuracy Of Taper Turning Operations?If your lathe isn’t level, it won’t work right. This can cause the tool to cut at the wrong angle. When that happens, your pieces can be crooked or tapered wrongly. It’s like trying to draw a straight line on a tilted table. To make good parts, we need to keep the lathe level.

What Techniques Can Be Used To Measure And Adjust The Tailstock Alignment On A Metal Lathe To Ensure Proper Taper Turning?To measure and adjust the tailstock on a metal lathe, you can use a few simple techniques. First, check the alignment with a test rod or a long piece of metal. If it tilts, you need to adjust the tailstock. You can loosen some screws, move the tailstock, and then tighten it again. Always recheck to make sure it’s straight after adjusting!

What Tools And Instruments Are Most Effective For Checking The Level And Alignment Of A Metal Lathe During Setup?To check the level and alignment of a metal lathe, you can use a few important tools. A level helps you see if the lathe is straight. A dial indicator measures very tiny movements or changes. You might also use straight edges to check for flat surfaces. These tools help make sure your lathe works correctly!

How Can The Effect Of Lathe Wear And Deflection Be Minimized When Performing Taper Turning On A Metal Lathe?To reduce lathe wear and deflection, use sharp cutting tools. Make sure the tools are set right and tightened well. You should take small cuts instead of big ones. Regularly check and clean your lathe to keep it in good shape. This way, you can make better tapers!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Taper Turning On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about using a metal lathe. First, why is leveling important for a lathe? Leveling helps the lathe work correctly and makes better parts. Second, what is taper turning? Taper turning means shaping an object so one end is thinner than the other. Third, how can you check if the lathe is level? You can use a level tool to see if the surface is flat. Fourth, why do we want precise cuts? Precise cuts make sure the pieces fit together well. Lastly, how do you adjust the lathe for taper turning? You change the angle of the cutting tool to create the taper.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just go ahead and ask your question, and I’ll give you a short and simple answer!”}},{“@type”: “Question”,”name”: “What Are The Essential Steps For Achieving Precision Leveling Of A Metal Lathe Before Beginning Any Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, start by placing it on a flat surface. Use a level tool to check if it’s straight. If it’s not, adjust the legs until it is. Tighten all the bolts once it’s level. Finally, double-check the level to make sure it’s perfect before you begin working!”}},{“@type”: “Question”,”name”: “How Does Improper Leveling Of A Lathe Affect The Accuracy Of Taper Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe isn’t level, it won’t work right. This can cause the tool to cut at the wrong angle. When that happens, your pieces can be crooked or tapered wrongly. It’s like trying to draw a straight line on a tilted table. To make good parts, we need to keep the lathe level.”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Measure And Adjust The Tailstock Alignment On A Metal Lathe To Ensure Proper Taper Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and adjust the tailstock on a metal lathe, you can use a few simple techniques. First, check the alignment with a test rod or a long piece of metal. If it tilts, you need to adjust the tailstock. You can loosen some screws, move the tailstock, and then tighten it again. Always recheck to make sure it’s straight after adjusting!”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Most Effective For Checking The Level And Alignment Of A Metal Lathe During Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check the level and alignment of a metal lathe, you can use a few important tools. A level helps you see if the lathe is straight. A dial indicator measures very tiny movements or changes. You might also use straight edges to check for flat surfaces. These tools help make sure your lathe works correctly!”}},{“@type”: “Question”,”name”: “How Can The Effect Of Lathe Wear And Deflection Be Minimized When Performing Taper Turning On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce lathe wear and deflection, use sharp cutting tools. Make sure the tools are set right and tightened well. You should take small cuts instead of big ones. Regularly check and clean your lathe to keep it in good shape. This way, you can make better tapers!”}}]}