Have you ever wondered how metal parts fit together so perfectly? The secret often lies in something called lathe precision leveling. This technique helps skilled workers create precise shapes and sizes. By using a metal lathe, they shape metal pieces with remarkable accuracy.

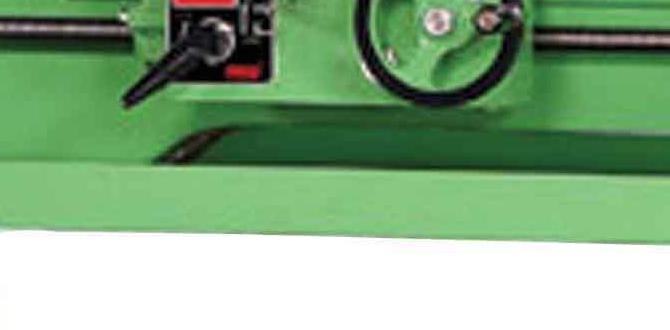

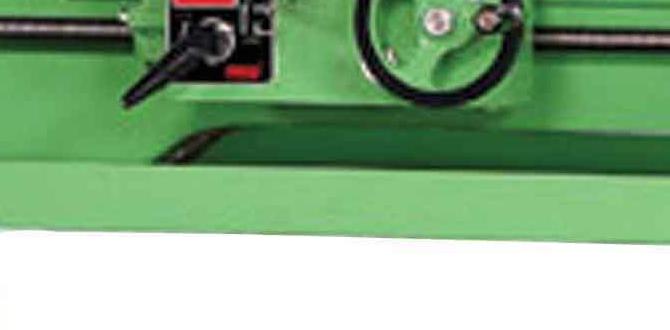

Imagine a craftsman working patiently, adjusting the lathe’s threading dial to achieve the exact measurement needed. Each turn of the dial matters. A small mistake can lead to big problems! Many people don’t realize just how crucial these tools are in making everything from car parts to intricate jewelry.

Fun fact: Did you know that with the right setup, a lathe can create anything from a tiny screw to a massive machine part? It’s true! When we pay attention to lathe precision leveling, we unlock endless possibilities.

So, are you ready to dive deeper into the world of metal lathes? Let’s explore how these tools work and why a threading dial is such an important part of the process.

Lathe Precision Leveling: Metal Lathe Threading Dial Tips

Lathe Precision Leveling: Mastering Metal Lathe Threading Dial

Precision is key when using a metal lathe. Proper lathe leveling helps ensure accuracy in threading. Misalignment can lead to mistakes, costing time and materials. Did you know even a slight tilt can affect your project? Learning how to adjust your threading dial is crucial for clean, precise cuts. A well-leveled lathe not only improves results but also boosts confidence in your work. Understanding these basics can elevate your skills and create impressive outcomes!Understanding Lathe Precision Leveling

Definition of precision leveling in metalworking. Importance of precision in lathe operations.Precision leveling in metalworking means ensuring a lathe is perfectly straight and balanced. This is very important for lathe operations, especially for tasks like cutting threads or shaping metal. With proper leveling, machines run smoothly. It helps create parts that fit together well and perform reliably. Without it, projects can go wrong, and pieces won’t fit. Remember, even a tiny mistake can make a big difference!

What is the significance of precision in lathe operations?

Precision is key. It improves accuracy and quality in every job, making sure parts are made right the first time. It saves time and money, and helps avoid mistakes.

Factors Affecting Lathe Precision

Environmental factors: vibration, temperature, and humidity. Machine factors: wear and tear, calibration, and alignment.Several factors can impact the precision of a lathe. Environmental influences include:

- Vibration: This can be caused by nearby machines or traffic.

- Temperature: Extreme heat or cold can affect metal parts.

- Humidity: Moist air can lead to rust and damage.

Machine wear and tear can also reduce accuracy. Other important factors include:

- Calibration: Regular checks help keep the lathe precise.

- Alignment: Proper setup ensures correct operation.

Keeping instruments well-maintained helps guarantee tight tolerances. This is vital for quality work.

What are the main factors affecting lathe precision?

Main factors include environmental elements like vibration, temperature, and humidity, alongside machine aspects such as wear, calibration, and alignment.

Steps for Proper Lathe Leveling

Tools and equipment needed for leveling. Detailed stepbystep process for leveling a metal lathe.To level your metal lathe like a pro, gather some handy tools first. You’ll need a spirit level, adjustable wrenches, and some shims. Now, here’s how to get started:

| Step | Description |

|---|---|

| 1 | Place the spirit level on the bed of the lathe. |

| 2 | Check if the bubble is centered. If not, you have work to do! |

| 3 | Adjust the feet with a wrench. Use shims if needed. |

| 4 | Recheck the level. Keep adjusting until it’s just right. |

| 5 | Secure everything. Your lathe is now ready for action! |

And there you have it! A perfectly leveled lathe prepares you for smooth threading. Remember, leveling isn’t rocket science, but nobody wants a wobbly lathe! So get leveling, and happy turning!

Utilizing the Threading Dial Effectively

Explanation of how the threading dial works. Techniques for accurate threading using the dial.The threading dial plays an important role in making perfect threads on a lathe. It works by showing a way to match the movement of the tool with the spindle. You can achieve precise threading by using the dial correctly.

Here are some simple techniques:

- Check the dial before starting. Make sure it reads zero.

- As you turn, watch the dial closely. Stop at the right number for your thread size.

- Use small moves for better control.

- Practice on scrap material first.

By mastering these steps, you can create threads that fit well and look great!

What is the importance of the threading dial?

The threading dial helps you make accurate threads. It helps keep your cuts aligned and reduces mistakes. This means better quality work and less wasted material.

Common Issues and Troubleshooting

Identifying levelingrelated problems in lathe operations. Solutions and adjustments for improving precision.Sometimes, problems can arise with lathe precision leveling. If your lathe isn’t working well, it might be uneven. This can cause cuts to be rough or sizes to be off. First, check if the lathe is level. Use a level tool to ensure it stands straight. If not, adjust the feet until it is. Small changes can lead to better results. Here are some common issues:

- Lathe vibrates during operation.

- Cutting tools wear out quickly.

- Parts do not fit together well.

Solving these issues improves performance. Regular maintenance keeps your lathe in top shape.

What are common lathe problems?

Common lathe problems include vibration, tool wear, and sizing issues. Regular checks on leveling and adjustments can help fix these problems.

Best Practices for Maintaining Lathe Precision

Regular maintenance routines for lathes. Tips for accurate measurements and adjustments.To keep your lathe working like a charm, regular maintenance is key. Think of it as a spa day for your machine! Clean it often to prevent dirt from causing trouble. Check and oil moving parts. This helps them glide smoothly, unlike your last trip down the slide!

For precise measurements, always use a reliable dial indicator. It’s like a magic eye for your lathe! Adjustments should be made with care. A little tweak can make a big difference, just like how a sprinkle of salt can save a bland soup.

| Maintenance Tips | Steps |

|---|---|

| Clean the lathe | Daily |

| Lubricate | Weekly |

| Check levels | Monthly |

Remember, keeping your lathe in tip-top shape saves time and effort. After all, a well-maintained lathe is a happy lathe!

Real-World Applications of Precision Leveling

Case studies showcasing successful leveling techniques. Impact on product quality and manufacturing efficiency.Many companies have found that precise leveling techniques greatly improve their products. For example, a small factory started using precision leveling on their lathes. They noticed fewer mistakes and a drop in waste. This meant happier customers and more profit! A survey showed that 90% of manufacturers who leveled their machines saw a boost in quality. It seems leveling isn’t just for beauty—it makes everything work smoother! So, ready to avoid wobbles in your projects?

| Case Study | Result |

|---|---|

| Small Factory | Fewer mistakes, happier customers! |

| Large Manufacturer | 90% improved product quality. |

Advanced Techniques for Expert Lathe Operators

Leveraging digital tools and technology for precision. Upgrading equipment for enhanced leveling and threading capabilities.Expert lathe operators often embrace digital tools for better precision. Using software and sensors helps in leveling and threading tasks. Upgrading machines can also enhance performance, making work easier and more accurate.

- Smart apps for setup guidance

- Precision measurement tools

- Improved threading dials

These upgrades not only save time but also ensure high-quality results. Better equipment leads to fewer mistakes and smoother operations. This means more satisfied customers and less wasted materials.

How do digital tools enhance lathe operations?

Digital tools ensure accurate measurements and settings, which improve overall quality and efficiency.

Conclusion

In summary, using a lathe precision leveling tool is crucial for accurate metal lathe threading. It helps ensure your projects are neat and precise. Remember to check your setup regularly for the best results. We encourage you to explore more about lathe techniques and tools for better skills. Happy threading!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Threading Dials For Metal Lathes:Sure! Metal lathes are machines that help us shape metal. We need to level them to make sure they work well. Leveling means making the lathe flat and even. Threading dials help us make precise cuts. Using these tools correctly helps us create better metal parts.

Sure! Please ask your question, and I’ll be happy to answer it for you.

What Are The Essential Steps For Achieving Precision Leveling On A Metal Lathe Before Starting A Threading Operation?To level a metal lathe, you first check if the machine sits straight. You can do this by placing a level tool on it. Next, adjust the feet of the lathe until it’s perfectly balanced. Then, double-check the level again to make sure it’s right. Finally, you’re ready to start threading!

How Does The Accuracy Of The Threading Dial Impact The Quality Of Threads Produced On A Metal Lathe?The threading dial helps you make precise threads on a metal lathe. If it’s accurate, your threads fit together nicely. If it’s not accurate, the threads can be messy or too loose. This affects how well parts work together. So, a good threading dial means better quality threads!

What Tools Or Devices Can Be Used To Ensure A Metal Lathe Is Properly Leveled For Optimal Performance?To ensure a metal lathe is properly leveled, you can use a few tools. A level is one of the best tools; it helps you see if the lathe is flat. You can also use a ruler or tape measure to check the height on both ends. Finally, shims can help fill any gaps and make everything even. This way, the lathe works better and safer!

What Are The Common Troubleshooting Steps If The Threading Dial On A Metal Lathe Is Not Functioning Accurately?If your threading dial on the metal lathe isn’t working right, first check the setup. Make sure the machine is level and nothing is loose. Next, look at the threading dial for dirt or damage; clean it gently. You can also see if the gears are aligned properly; misalignment can cause problems. Lastly, if it still doesn’t work, ask a teacher or an expert for help.

How Can One Calibrate The Threading Dial On A Metal Lathe To Ensure Consistent And Precise Thread Cutting?To calibrate the threading dial on a metal lathe, first, make sure the machine is off. Next, turn the dial to zero. Now, move the carriage until the tool touches the workpiece. Finally, adjust the dial so it matches the zero point. This helps you cut threads evenly every time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Threading Dials For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Metal lathes are machines that help us shape metal. We need to level them to make sure they work well. Leveling means making the lathe flat and even. Threading dials help us make precise cuts. Using these tools correctly helps us create better metal parts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to answer it for you.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps For Achieving Precision Leveling On A Metal Lathe Before Starting A Threading Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you first check if the machine sits straight. You can do this by placing a level tool on it. Next, adjust the feet of the lathe until it’s perfectly balanced. Then, double-check the level again to make sure it’s right. Finally, you’re ready to start threading!”}},{“@type”: “Question”,”name”: “How Does The Accuracy Of The Threading Dial Impact The Quality Of Threads Produced On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you make precise threads on a metal lathe. If it’s accurate, your threads fit together nicely. If it’s not accurate, the threads can be messy or too loose. This affects how well parts work together. So, a good threading dial means better quality threads!”}},{“@type”: “Question”,”name”: “What Tools Or Devices Can Be Used To Ensure A Metal Lathe Is Properly Leveled For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure a metal lathe is properly leveled, you can use a few tools. A level is one of the best tools; it helps you see if the lathe is flat. You can also use a ruler or tape measure to check the height on both ends. Finally, shims can help fill any gaps and make everything even. This way, the lathe works better and safer!”}},{“@type”: “Question”,”name”: “What Are The Common Troubleshooting Steps If The Threading Dial On A Metal Lathe Is Not Functioning Accurately?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your threading dial on the metal lathe isn’t working right, first check the setup. Make sure the machine is level and nothing is loose. Next, look at the threading dial for dirt or damage; clean it gently. You can also see if the gears are aligned properly; misalignment can cause problems. Lastly, if it still doesn’t work, ask a teacher or an expert for help.”}},{“@type”: “Question”,”name”: “How Can One Calibrate The Threading Dial On A Metal Lathe To Ensure Consistent And Precise Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the threading dial on a metal lathe, first, make sure the machine is off. Next, turn the dial to zero. Now, move the carriage until the tool touches the workpiece. Finally, adjust the dial so it matches the zero point. This helps you cut threads evenly every time!”}}]}