Have you ever wondered how metal parts are shaped so perfectly? It often starts with a machine called a lathe. A lathe helps create smooth and precise products from metal. But wait! There’s more to it than just turning metal. Precise leveling is important too.

Imagine trying to build a tower of blocks. If the base is not level, the tower will fall over. The same goes for metal lathe tools. If a lathe isn’t level, it can make mistakes in cutting and shaping. This is why lathe precision leveling matters!

Not many people know that a small mistake in leveling can lead to major problems. It can affect the quality of your work and waste time and materials. A properly leveled lathe makes sure everything runs smoothly. This way, you can focus on creating amazing metal designs!

So, whether you are a beginner or a pro, understanding lathe precision leveling can change the way you work with metal. Let’s dive deeper into this exciting world and explore the tools that make it all happen!

Lathe Precision Leveling: Essential Metal Lathe Tools Guide

Lathe Precision Leveling Metal Lathe Tools

Discover how vital lathe precision leveling is for using metal lathe tools effectively. Properly leveling your lathe ensures accurate cuts and reduces wear on your tools. Without this, you might end up with uneven surfaces and poor finishes. Did you know that even slight misalignments can lead to big mistakes in your projects? By mastering this skill, you enhance your craftsmanship and ensure your creations are top-notch. Let the magic of precision work for you!Understanding Lathe Precision Leveling

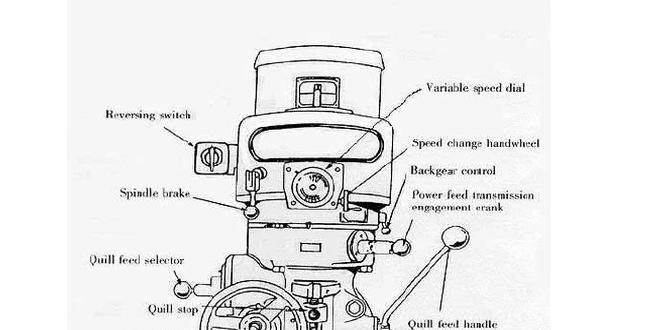

Definition of lathe precision leveling. Importance of precision leveling in machining.Lathe precision leveling is making sure a lathe machine is flat and straight. This is important because it helps the machine work better. When the machine is level, it cuts materials smoothly and accurately. If not, it may cause mistakes in the work. Here’s why precision leveling matters:

- It improves accuracy in cutting.

- It reduces wear and tear on tools.

- It ensures safety during use.

Why is precision leveling important?

Precision leveling helps machines work better. It leads to cleaner cuts and helps tools last longer. This means more successful projects and less waste. Keeping the lathe level is key for great results.

The Impact of Leveling on Lathe Performance

Effects of improper leveling on machining accuracy. How precision leveling enhances surface finish and tool life.Leveling your lathe machine is essential for good performance. If your machine is not level, it can cause errors. This can hurt the accuracy of your work. It can also lead to rough surfaces on your pieces. Proper leveling helps in many ways:

- Improves machining accuracy

- Enhances surface finish

- Increases tool life

By keeping your lathe level, you’ll make better parts that last longer. This means spending less time fixing mistakes.

Why is leveling important for lathe operations?

Leveling is crucial because it ensures accuracy and quality in machining tasks. A well-leveled lathe helps in crafting better products with a smooth finish.

Step-by-Step Guide to Leveling a Metal Lathe

Initial assessment and preparation. Detailed leveling process: techniques and tips.Before you start leveling your metal lathe, check the area for any bumps or dirt. Clean the floor to give a flat surface. You’ll need some tools like a level, gauge blocks, and shims for precision. Follow these steps:

- Set the lathe on a stable base.

- Use a level to check if the lathe is flat.

- If not, adjust using shims.

- Double-check after every change.

- Finally, tighten all bolts to secure the lathe.

Remember, a well-leveled lathe can make your work easier and more accurate.

How important is leveling for a metal lathe?

Leveling your metal lathe ensures accuracy in your work. An uneven lathe can cause mistakes and damage parts. Spending time on leveling pays off in the long run.

Common Challenges in Lathe Leveling and Solutions

Typical issues faced during leveling. Troubleshooting tips for effective precision leveling.Leveling a lathe can feel like trying to balance a spoon on your nose. Common issues include uneven surfaces and loose screws. These problems can mess up your work. So, what can you do? Here’re some troubleshooting tips:

| Issue | Solution |

|---|---|

| Uneven surface | Check the base and adjust feet. |

| Loose screws | Tighten all screws, no wiggly bits allowed! |

| Inaccurate readings | Use a level tool for a fair fight. |

Remember, precision is key! Like baking a cake, you don’t want too much or too little. Follow these tips, and your lathe will be a star performer!

Maintaining Lathe Precision After Leveling

Best practices for regular maintenance. Monitoring techniques to ensure ongoing precision.To keep your lathe working well, regular checks are important. A well-maintained lathe runs smoothly and makes better parts. Follow these tips for maintenance:

- Clean the lathe often. Dust and chips can affect precision.

- Check levels regularly. Small changes matter!

- Lubricate moving parts. This helps them last longer.

- Inspect for wear. Replace parts that look worn out.

Monitor precision by making simple checks. Use a dial indicator to see if the cuts are accurate. Using these steps keeps your tools working well and ensures ongoing precision.

What are the best practices for maintaining lathe precision?

Best practices include regular cleaning, lubrication, and inspection to find issues before they become problems.

Comparative Analysis of Different Leveling Techniques

Review of traditional vs. modern leveling methods. Advantages and disadvantages of each approach.Leveling techniques have come a long way. Traditional methods often use spirit levels and measuring tapes. They are simple but can be inaccurate. Modern techniques rely on laser systems and digital tools. These tools give precise readings and save time. Here’s a quick look at the advantages and disadvantages:

- Traditional Methods:

- Advantages: Simple and cheap.

- Disadvantages: Less accurate and time-consuming.

- Modern Methods:

- Advantages: Highly accurate and efficient.

- Disadvantages: More expensive and may need training.

What are traditional leveling methods?

Traditional leveling methods include using tools like spirit levels and plumb bobs. They are easy to use but require skill for accurate results.

What are modern leveling techniques?

Modern leveling techniques use laser levels and digital devices. They provide quick and accurate measurements, making them ideal for professional use.

Expert Tips for Achieving Optimal Lathe Precision

Insights from experienced machinists. Recommended practices for precision machining.To get the most out of your lathe, listen to seasoned machinists. Their experience can save you time and headaches. First, always check your lathe’s level. A wobbly machine can ruin your work faster than a cat knocking over a vase!

Next, regularly inspect your tools. Sharp tools create better finishes and last longer. Keep everything clean to avoid hiccups during production. Don’t forget to measure twice; cutting once can be a costly mistake!

| Tip | Description |

|---|---|

| Level the Lathe | Ensure your lathe is level to prevent uneven cuts. |

| Inspect Tools | Check for sharpness to improve precision and quality. |

| Keep Clean | A tidy workspace prevents errors and helps you focus. |

| Measure Twice | Double-check your measurements to avoid waste. |

These simple steps can lead to amazing results. Remember, even a tiny mistake can make a big mess. Happy machining!

Conclusion

In conclusion, lathe precision leveling is crucial for using metal lathe tools effectively. It helps you create accurate and smooth cuts. Always check your leveling before starting a project. For better results, practice and experiment with different techniques. You can also read more about lathe tools online to deepen your understanding. Take these steps, and watch your skills improve!FAQs

Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Tools:To make sure a lathe works well, we need to level it perfectly. Leveling keeps the lathe steady. When you use the right tools, like chisels and cutting bits, it helps you create nice shapes in metal. Remember, a level lathe is safer and makes better projects. Always check your tools and lathe before starting!

Sure! Just let me know what question you want me to answer, and I’ll keep it simple and easy to understand.

What Are The Key Steps Involved In Properly Leveling A Metal Lathe To Ensure Precision Machining?To level a metal lathe, you start by placing it on a flat surface. Use a bubble level to check if it’s straight. If it’s not, adjust the feet of the lathe until it is level. After that, recheck with the level to make sure. Finally, tighten everything up so it stays in place while you work.

How Does The Use Of Precision Leveling Tools, Such As Spirit Levels And Dial Indicators, Enhance The Accuracy Of Metal Lathe Operations?Using precision leveling tools like spirit levels and dial indicators helps us make sure everything is straight and even. When we use these tools, we can find tiny mistakes that could make our work less accurate. This means the pieces we make on the metal lathe will fit better and work properly. By checking things closely, we improve the quality of our projects. So, using these tools helps us do a great job!

What Common Issues Can Arise From An Improperly Leveled Lathe, And How Can They Affect The Quality Of The Finished Workpiece?If a lathe is not level, it can cause several problems. First, the cutting tool might not touch the material evenly. This can make the finished piece have bumps or uneven parts. You might also see more noise and vibration, which can hurt the machine. All these issues mean your work won’t look or work as good as it should.

What Materials And Techniques Are Recommended For Constructing A Stable Foundation Or Base For A Metal Lathe To Ensure Optimal Leveling?To build a stable base for a metal lathe, you can use heavy materials like concrete or steel. First, make sure the ground is flat. Then, place your base on strong blocks or a thick wooden table. You can use screws to secure it tightly. Finally, check that it is level by using a level tool.

How Can Periodic Maintenance And Recalibration Of Leveling Tools Help Maintain Long-Term Precision In Lathe Operations?Taking care of our leveling tools is really important. By checking and fixing them regularly, we can make sure they work correctly. This helps us get better results when using the lathe, which is a machine that shapes materials. If we don’t maintain them, they might give us wrong measurements. So, keeping our tools in good shape helps us make things that are just right!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a lathe works well, we need to level it perfectly. Leveling keeps the lathe steady. When you use the right tools, like chisels and cutting bits, it helps you create nice shapes in metal. Remember, a level lathe is safer and makes better projects. Always check your tools and lathe before starting!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll keep it simple and easy to understand.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Properly Leveling A Metal Lathe To Ensure Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you start by placing it on a flat surface. Use a bubble level to check if it’s straight. If it’s not, adjust the feet of the lathe until it is level. After that, recheck with the level to make sure. Finally, tighten everything up so it stays in place while you work.”}},{“@type”: “Question”,”name”: “How Does The Use Of Precision Leveling Tools, Such As Spirit Levels And Dial Indicators, Enhance The Accuracy Of Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using precision leveling tools like spirit levels and dial indicators helps us make sure everything is straight and even. When we use these tools, we can find tiny mistakes that could make our work less accurate. This means the pieces we make on the metal lathe will fit better and work properly. By checking things closely, we improve the quality of our projects. So, using these tools helps us do a great job!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From An Improperly Leveled Lathe, And How Can They Affect The Quality Of The Finished Workpiece?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe is not level, it can cause several problems. First, the cutting tool might not touch the material evenly. This can make the finished piece have bumps or uneven parts. You might also see more noise and vibration, which can hurt the machine. All these issues mean your work won’t look or work as good as it should.”}},{“@type”: “Question”,”name”: “What Materials And Techniques Are Recommended For Constructing A Stable Foundation Or Base For A Metal Lathe To Ensure Optimal Leveling?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a stable base for a metal lathe, you can use heavy materials like concrete or steel. First, make sure the ground is flat. Then, place your base on strong blocks or a thick wooden table. You can use screws to secure it tightly. Finally, check that it is level by using a level tool.”}},{“@type”: “Question”,”name”: “How Can Periodic Maintenance And Recalibration Of Leveling Tools Help Maintain Long-Term Precision In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taking care of our leveling tools is really important. By checking and fixing them regularly, we can make sure they work correctly. This helps us get better results when using the lathe, which is a machine that shapes materials. If we don’t maintain them, they might give us wrong measurements. So, keeping our tools in good shape helps us make things that are just right!”}}]}