Have you ever wondered why some metal lathes work better than others? One key factor is lathe precision leveling. It might sound technical, but it’s really about how level your machine is. When a metal lathe is not level, it can create parts that don’t fit right or look perfect.

Upgrading your lathe to ensure precision leveling might change everything. Imagine being able to make parts that are spot on every time. Isn’t that exciting? A well-leveled lathe gives you better control. It helps in making smooth cuts and achieving finer details.

Funny enough, even a tiny tilt can make a big difference. Sometimes, people overlook this simple upgrade. They focus on fancy tools or complex techniques. But leveling your lathe can be the best upgrade you make.

Let’s dive into how you can level your lathe. Explore ways that this small change can lead to amazing improvements in your projects!

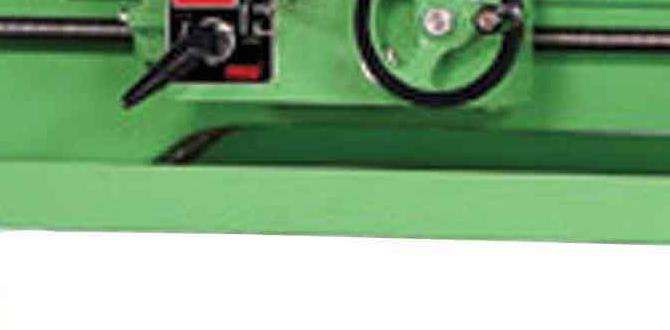

Lathe Precision Leveling: Essential Metal Lathe Upgrade Guide

Lathe Precision Leveling: Metal Lathe Upgrade

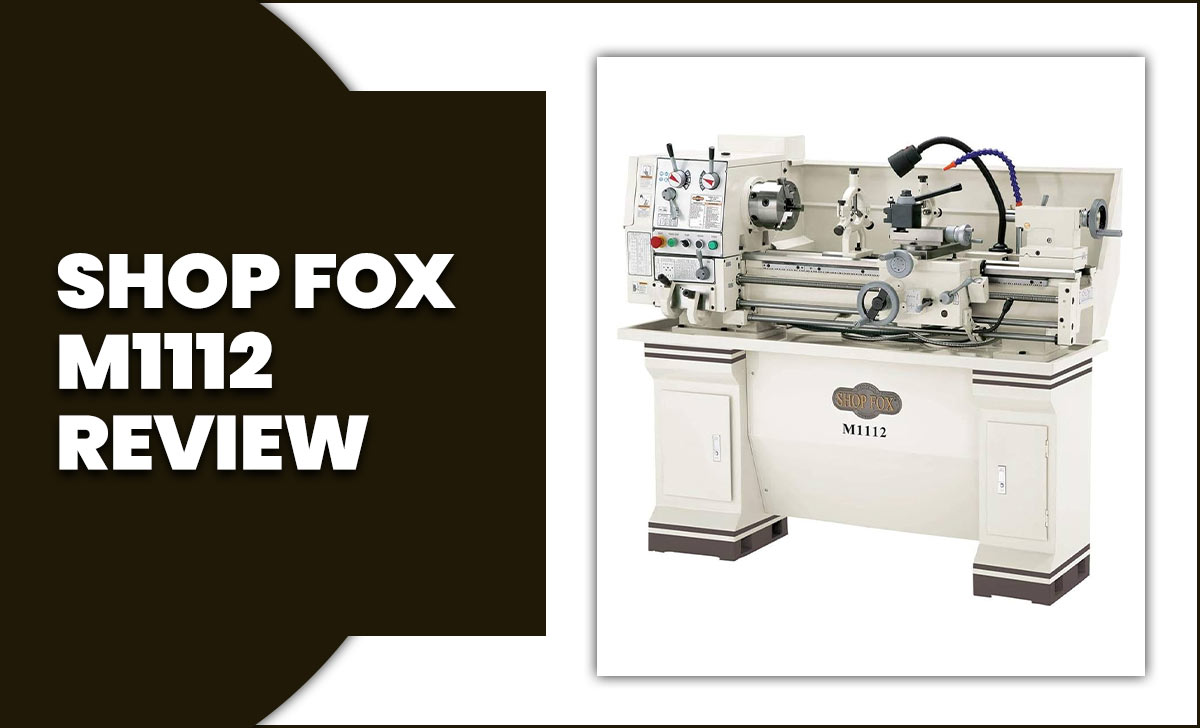

Upgrading a metal lathe with precision leveling can greatly enhance your machining quality. When the lathe is leveled correctly, it improves accuracy, reduces wear, and boosts overall performance. Ever wonder why some lathes produce cleaner cuts? Proper leveling eliminates unnecessary vibrations. Imagine crafting parts with perfect symmetry! This upgrade is essential for anyone looking to take their metalworking skills to the next level. Don’t miss the chance to elevate your projects with better precision.Understanding Lathe Precision Leveling

Definition of precision leveling in the context of metal lathes. Importance of precision leveling for accuracy and performance.Precision leveling is a way to ensure that metal lathes stay balanced and straight. This process helps the machine work correctly. It matters a lot because precision affects how well the lathe cuts metal. If the lathe is not level, the pieces might be uneven or wrong. This could lead to mistakes and wasted material. Keeping your lathe level ensures accuracy and boosts performance.

Why is precision leveling important?

Precision leveling helps improve the quality of your work. It keeps your lathe running smoothly, which saves time and reduces errors.

Signs Your Metal Lathe Needs Leveling

Common symptoms of an unlevel lathe affecting performance. How to conduct a preliminary assessment of your lathe’s level.If your metal lathe feels more like a wobbly roller coaster than a steady workhorse, it might be time for some leveling action! Signs include uneven cuts, vibrations, and poor accuracy. These symptoms can frustrate even the most patient of machinists. To check your lathe’s level, use a simple level tool. Place it on the bed and see if it balances. If it tilts, your lathe needs some TLC.

| Signs of an Unlevel Lathe | Effects on Performance |

|---|---|

| Uneven Cuts | Not a smooth experience! |

| Vibrations | Like a rock concert, but not fun. |

| Poor Accuracy | A tool that misses the mark! |

Benefits of Upgrading Your Metal Lathe

Enhanced accuracy and consistency in machining operations. Improvement in tool wear and overall productivity.Upgrading your metal lathe offers great benefits. First, it improves how accurately machines work. You will notice less mistakes, making each cut cleaner. That means enhanced accuracy is key. Second, better tools last longer. This leads to less wear on equipment, saving money in the long run. Lastly, all these upgrades can boost overall productivity, allowing you to complete tasks faster and with better results.

What are the key benefits of metal lathe upgrades?

Upgrades enhance accuracy, save tools from wear, and increase productivity.Summary of Benefits:

- Less mistakes in machining

- Longer tool life

- Faster project completion

Tools and Equipment Needed for Lathe Leveling

Essential tools required for leveling a metal lathe. Recommended equipment for a successful upgrade.Leveling your metal lathe trims any wobble and makes your projects smoother. Start with a spirit level for a quick check. Then grab a dead blow hammer to make gentle adjustments without damaging your lathe. A wrench set is crucial for tightening loose bolts. Lastly, consider a precision ruler to ensure everything is spot-on. Think of these tools as your lathe’s best friends; they’ll help it stand tall and true—like a proud giraffe!

| Tool | Purpose |

|---|---|

| Spirit Level | Checks if the lathe is level. |

| Dead Blow Hammer | Adjusts without damage. |

| Wrench Set | Tightens loose bolts. |

| Precision Ruler | Ensures exact measurements. |

Step-by-Step Guide to Leveling Your Metal Lathe

Detailed instructions on leveling procedures. Tips for achieving optimal results during the process.Leveling your metal lathe makes it work better. Follow these precise steps for great results:

- Make sure the lathe is on a stable surface.

- Use a spirit level. Place it on the bed of the lathe.

- Adjust the feet of the lathe until the bubble is centered.

- Check both sides of the machine for evenness.

For best outcomes, adjust slowly and recheck often. This ensures perfect alignment. A well-leveled lathe reduces errors and improves your projects!

How can I achieve optimal results while leveling my lathe?

Stay patient and double-check every adjustment. Small changes can make a big difference. If needed, use shims for extra support. Also, maintain your lathe regularly for the best performance.

Common Mistakes to Avoid During Lathe Leveling

List of frequent errors made when leveling a lathe. Strategies to prevent these mistakes and ensure accuracy.Leveling a lathe can be tricky. Many make errors that can affect their work. Here are common mistakes to avoid:

- Not checking the surface underneath.

- Ignoring the manufacturer’s instructions.

- Forgetting to use a level tool.

- Not checking for warp or damage in the lathe.

- Rushing through the leveling process.

To prevent these mistakes:

- Ensure a clean, flat surface.

- Follow guidelines carefully.

- Use a reliable leveling tool.

- Regularly inspect your lathe.

- Take your time and double-check results.

By avoiding these errors, you can enhance the lathe precision leveling metal lathe upgrade. Accuracy matters for quality work!

What are ways to improve lathe leveling?

Practice careful measurement and check the setup frequently.Maintenance Tips for Sustaining Lathe Precision

Regular maintenance practices to uphold leveling. Importance of periodic checks for continued performance.To keep your lathe working like a well-oiled machine, regular maintenance is key! It’s essential to check your machine frequently. This means cleaning the bed and ensuring everything is straight. Imagine your lathe is like a pet—it needs love to stay healthy! Schedule routine inspections to catch any tiny issues before they become major problems. Remember, a little care can make a big difference.

| Maintenance Task | Frequency |

|---|---|

| Clean the machine | Every use |

| Inspect level | Weekly |

| Check lubrication | Monthly |

Without proper checks, your lathe might just throw a temper tantrum and ruin your work. Keeping everything aligned helps maintain precision, ensuring you create the best pieces possible. So, be a fantastic lathe parent and keep your machine happy!

Case Studies: Success Stories of Lathe Upgrades

Realworld examples of operators benefiting from lathe leveling. Analysis of productivity improvements postupgrade.Many operators have exciting stories about how upgrading their lathes changed their work. For example, one shop saw a 20% boost in production after leveling their lathe. This upgrade helped them make precise cuts without mistakes. Another shop reduced their waste by 30% thanks to better alignment. These examples show how important lathe leveling is for success.

- Increased Efficiency: Operators cut down production time.

- Better Quality: Upgrades lead to fewer errors.

- Less Waste: Reducing scrap materials saves money.

How do lathe upgrades improve work?

Lathe upgrades improve work by enhancing precision and cutting down time. This helps workers create better products faster!

Conclusion

In conclusion, upgrading your metal lathe with precision leveling can boost accuracy and performance. This simple improvement helps achieve better results in your projects. By understanding how to level your lathe properly, you enhance your work quality. We encourage you to explore more about this topic. Try leveling your lathe today and experience the difference!FAQs

What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe During Setup?To level a metal lathe, start by placing it on a sturdy, flat surface. Use a level tool to check if it’s even. If one side is low, you can adjust its feet or add shims to lift it. Make sure to lock everything in place once it’s level. Finally, double-check the level again to be sure.

How Can Upgrading The Leveling System Of A Metal Lathe Improve Its Machining Accuracy?Upgrading the leveling system of a metal lathe helps it stay steady and balanced. When we level the lathe correctly, it can cut metal more precisely. A good level means fewer mistakes, which gives us better shapes and sizes. We can make our projects fit together perfectly. In short, a better leveling system helps us make things more accurate.

What Tools And Equipment Are Recommended For Precise Leveling Of A Metal Lathe?To level a metal lathe, you should use a few important tools. First, a spirit level helps measure if the lathe is even. You might also need metal shims to fill in any gaps under the lathe. A tape measure can help you check distances. Lastly, a wrench is useful for tightening bolts and securing everything in place.

What Are Common Signs That Indicate A Metal Lathe Requires Leveling Or Calibration?If your metal lathe makes uneven cuts, it might need leveling. You can also check for wobbly parts or loud noises when it runs. If the pieces you make don’t fit together, calibration might be off. Keep an eye out for these signs to let you know it’s time to adjust your lathe.

How Does The Environmental Setup Of A Workshop Impact The Precision Leveling Of A Metal Lathe?The workshop’s environment is important for using a metal lathe. If the floor is uneven, the lathe won’t be level. Dust, heat, and cold can also affect the lathe’s parts. Keeping the area clean and at a steady temperature helps the lathe work better. You want everything to be just right for making precise cuts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe During Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, start by placing it on a sturdy, flat surface. Use a level tool to check if it’s even. If one side is low, you can adjust its feet or add shims to lift it. Make sure to lock everything in place once it’s level. Finally, double-check the level again to be sure.”}},{“@type”: “Question”,”name”: “How Can Upgrading The Leveling System Of A Metal Lathe Improve Its Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the leveling system of a metal lathe helps it stay steady and balanced. When we level the lathe correctly, it can cut metal more precisely. A good level means fewer mistakes, which gives us better shapes and sizes. We can make our projects fit together perfectly. In short, a better leveling system helps us make things more accurate.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Recommended For Precise Leveling Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you should use a few important tools. First, a spirit level helps measure if the lathe is even. You might also need metal shims to fill in any gaps under the lathe. A tape measure can help you check distances. Lastly, a wrench is useful for tightening bolts and securing everything in place.”}},{“@type”: “Question”,”name”: “What Are Common Signs That Indicate A Metal Lathe Requires Leveling Or Calibration? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe makes uneven cuts, it might need leveling. You can also check for wobbly parts or loud noises when it runs. If the pieces you make don’t fit together, calibration might be off. Keep an eye out for these signs to let you know it’s time to adjust your lathe.”}},{“@type”: “Question”,”name”: “How Does The Environmental Setup Of A Workshop Impact The Precision Leveling Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The workshop’s environment is important for using a metal lathe. If the floor is uneven, the lathe won’t be level. Dust, heat, and cold can also affect the lathe’s parts. Keeping the area clean and at a steady temperature helps the lathe work better. You want everything to be just right for making precise cuts!”}}]}