Have you ever wondered how to make the perfect piece of furniture? The tools you use can make a big difference. Two popular tools in woodworking and metalworking are the metal lathe and the wood lathe. Each lathe has its strengths, and choosing the right one can change your project.

Now, think about building a chair. You want it to be sturdy and nice to look at. A wood lathe can help you shape beautiful legs. But what if you needed to create precise, metal parts for a bicycle? That’s where a metal lathe shines.

Another interesting thing is how important leveling is for both types of lathes. Imagine trying to carve wood on a wobbly surface! It would be a mess. Lathe precision leveling is key to making sure your projects come out just right.

Join us as we explore the differences between metal lathes and wood lathes. You’ll discover which tool is best for your next project!

Lathe Precision Leveling: Metal Lathe Vs Wood Lathe

Metal Lathe vs. Wood Lathe: Precision Leveling

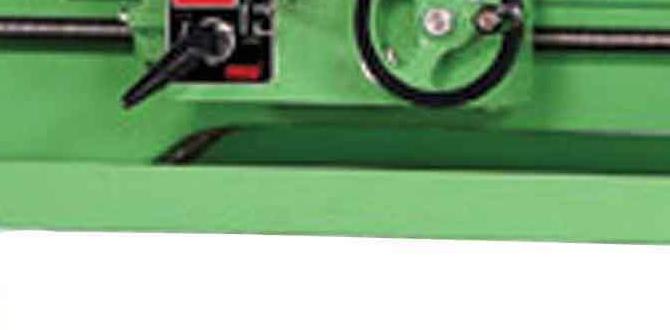

Metal lathes and wood lathes serve different purposes. Metal lathes are designed for high precision, often used in engineering and machining. They create fine details in metal, ideal for parts that must fit perfectly. In contrast, wood lathes focus on shaping and smoothing wood for crafts. While both types need leveling, metal lathes require precise adjustments to avoid errors. Choosing the right lathe can make all the difference in your project. Have you ever noticed how a tiny miscalculation can ruin a masterwork?Understanding Lathe Types

Definition and purpose of metal lathes. Definition and purpose of wood lathes.Metal lathes and wood lathes are tools for shaping materials. A metal lathe cuts and forms metal. It is precise and strong. This type is often used in factories and workshops. On the other hand, a wood lathe shapes wood. It is used by carpenters and hobbyists. Both lathes help create smooth and beautiful objects.

What is the purpose of both lathes?

Metal lathes make parts for machines. They are crucial in engineering. Wood lathes are for crafting furniture and art. They enhance creativity.

- Metal lathes: Great for fine detail and strong pieces.

- Wood lathes: Perfect for artistic designs and smooth finishes.

Precision Leveling in Metal Lathes

Importance of precision leveling in metal lathes. Common techniques and tools for leveling.Precision leveling is the superhero of metal lathes! It ensures your tools stay on point, making each cut smooth and accurate. Imagine trying to slice a cake on a wobbly table—chaos, right? That’s why leveling is key. Common tools include gauge blocks and leveling screws. These help align your lathe perfectly. Remember, a well-leveled lathe is like a happy cat: it works better and avoids unnecessary drama!

| Technique/Tool | Purpose |

|---|---|

| Gauge Blocks | Ensure height accuracy. |

| Leveling Screws | Adjust the height of the lathe. |

| Bubble Level | Visual check for leveling. |

Precision Leveling in Wood Lathes

Importance of precision leveling in wood lathes. Common techniques and tools for leveling.Precision leveling is key for wood lathes. It helps create smooth and even cuts, leading to better wood projects. If the lathe isn’t level, the wood may wobble, causing mistakes. Common techniques for leveling include using a spirit level or leveling feet. Tools like shim wedges can help adjust the height. Remember, taking time to level can make your projects look professional!

Why is leveling important in wood lathes?

Leveling is important because it ensures accurate cuts and smooth finishes. A lathe that is not level can lead to uneven shaping and ruined pieces.

Common Techniques and Tools for Leveling

- Spirit Level: Check the lathe’s flatness.

- Shim Wedges: Adjust the height of the lathe.

- Leveling Feet: Help stabilize the lathe on uneven surfaces.

Comparison of Leveling Techniques

Key differences in leveling approaches between metal and wood lathes. Pros and cons of each technique.Metal and wood lathes use different methods to stay level. These techniques affect their performance and ease of use. Here are the main differences:

- Metal Lathes: Use precise leveling tools. This can create very accurate results. However, it’s more complicated.

- Wood Lathes: Have simpler leveling systems. They are easier for beginners but might not offer the same accuracy.

Each method has its ups and downs. Metal lathes are great for precision, while wood lathes are user-friendly. Knowing this helps you pick the right lathe for your projects.

What are the key differences between metal and wood lathe leveling techniques?

Metal lathes require precise and detailed leveling, while wood lathes focus more on user-friendliness and simplicity.

Factors Affecting Precision in Lathes

Material properties and their impact on precision. Environmental conditions and their influence on leveling.Several factors can affect precision in lathes. The type of material plays a big role. For example, denser metals may require more accurate setups than softer woods. If the lathe isn’t leveled well, even minor bumps can cause problems.

- Material properties: Hardness and density affect cutting accuracy.

- Environmental conditions: Temperature and humidity changes can impact measurements.

Keeping machines in a stable environment helps maintain precision. Remember, small changes in setup can lead to big differences in results!

How does material affect lathe precision?

Material hardness affects how a lathe cuts. Softer materials are easier, while harder ones need extra care.

What environmental factors influence lathes?

Temperature and humidity can change how the lathe operates. A stable place is key for accurate results.

Maintenance and Calibration

Regular maintenance practices for optimal precision. Calibration methods for both metal and wood lathes.To keep your lathe running smoothly, regular maintenance is key. Check for wear and tear often. This keeps your projects precise. Both metal and wood lathes need calibration. Calibrate your machine to ensure perfect accuracy every time. Here are a few maintenance tips:

- Clean the lathe after each use.

- Apply lubricant to moving parts.

- Check for any loose parts regularly.

- Store the lathe in a dry place.

Remember, proper care leads to better results!

What are the best calibration methods for lathes?

The best calibration methods include:

- Using a dial gauge to check axis alignment.

- Adjusting the tailstock and tool rest for accuracy.

- Testing with known good materials for precision.

Regular checks keep your lathe precise.

Applications and Use Cases

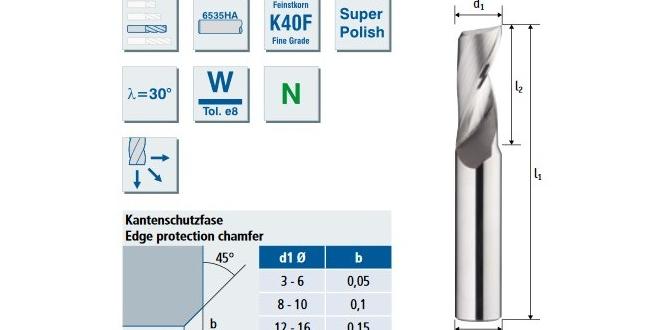

Common projects for metal lathes requiring high precision. Common projects for wood lathes where leveling is critical.Projects using metal lathes need precision. Common uses include:

- Creating precise machine parts

- Making tools and dies

- Manufacturing automotive components

For wood lathes, leveling is very important. Here are some typical projects:

- Turning bowls and vases

- Shaping furniture legs

- Crafting toys and decorative pieces

Expert Tips for Enhanced Precision Leveling

Best practices for achieving optimal results in metal lathes. Best practices for achieving optimal results in wood lathes.To improve precision leveling, follow these expert tips. For metal lathes, always check the surface plate for flatness. Use a reliable level to gauge accuracy. Clean the machine regularly to avoid debris buildup. For wood lathes, ensure the bed is clean and the tailstock is aligned. Always adjust your tool rest before starting. Taking these simple steps can lead to optimal results in your work.

How can I achieve greater precision in my lathing projects?

Align your equipment properly. Keeping everything level makes a big difference. This practice can help you create smoother cuts and finished products.

- Use proper tools.

- Measure twice, cut once.

- Have a clean workspace.

Conclusion

In conclusion, lathe precision leveling ensures your projects stay accurate. Metal lathes handle tough materials, while wood lathes shape softer woods. Each has unique benefits for different projects. If you’re starting, think about what you want to create. Explore more about lathes to find the best fit for your needs! Happy turning!FAQs

What Are The Key Differences In Precision Leveling Techniques Between Metal Lathes And Wood Lathes?Metal lathes and wood lathes use different ways to stay level. Metal lathes need to be very precise because they work with hard materials like steel. They often have special tools to measure and adjust exactly. Wood lathes can be less precise since wood is softer and easier to shape. This difference affects how we set them up and use them.

How Does The Material Being Turned (Metal Vs Wood) Affect The Requirements For Leveling A Lathe?The material you use on a lathe makes a difference in leveling it. When turning metal, you need the lathe to be very level. This helps make precise cuts. Wood is a bit more forgiving. It can handle slight bumps without ruining the shape. So, you might not need to level it as carefully for wood.

What Tools And Methods Are Recommended For Achieving Precise Leveling On A Metal Lathe Compared To A Wood Lathe?To level a metal lathe, you can use a machinist level. This tool helps you see if the lathe is flat and even. You should also use shims, which are small pieces of material, to lift part of the lathe if it’s low. For a wood lathe, you might not need to be as precise, so a regular level can work. Always check your lathe with the level before starting to make sure it runs smoothly.

How Does The Weight And Construction Of Metal Lathes Influence The Precision Leveling Process Compared To Lighter Wood Lathes?Metal lathes are heavier than wood lathes. This weight helps them stay steady and balanced. When we level a metal lathe, it is easier to make precise cuts. Wood lathes can shake more, which can affect how accurate our work is. So, the strong build of metal lathes makes them better for detailed jobs.

What Are The Potential Consequences Of Improper Leveling In Metal Lathes Versus Wood Lathes During Operation?If a metal lathe isn’t level, it can make loud noises and cause accidents. This can break the machine or hurt you. For wood lathes, being way off can make the wood splinter or get stuck. Both situations are frustrating, and you might waste your materials. Always check the level first to keep everything safe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences In Precision Leveling Techniques Between Metal Lathes And Wood Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes use different ways to stay level. Metal lathes need to be very precise because they work with hard materials like steel. They often have special tools to measure and adjust exactly. Wood lathes can be less precise since wood is softer and easier to shape. This difference affects how we set them up and use them.”}},{“@type”: “Question”,”name”: “How Does The Material Being Turned (Metal Vs Wood) Affect The Requirements For Leveling A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material you use on a lathe makes a difference in leveling it. When turning metal, you need the lathe to be very level. This helps make precise cuts. Wood is a bit more forgiving. It can handle slight bumps without ruining the shape. So, you might not need to level it as carefully for wood.”}},{“@type”: “Question”,”name”: “What Tools And Methods Are Recommended For Achieving Precise Leveling On A Metal Lathe Compared To A Wood Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you can use a machinist level. This tool helps you see if the lathe is flat and even. You should also use shims, which are small pieces of material, to lift part of the lathe if it’s low. For a wood lathe, you might not need to be as precise, so a regular level can work. Always check your lathe with the level before starting to make sure it runs smoothly.”}},{“@type”: “Question”,”name”: “How Does The Weight And Construction Of Metal Lathes Influence The Precision Leveling Process Compared To Lighter Wood Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes are heavier than wood lathes. This weight helps them stay steady and balanced. When we level a metal lathe, it is easier to make precise cuts. Wood lathes can shake more, which can affect how accurate our work is. So, the strong build of metal lathes makes them better for detailed jobs.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Improper Leveling In Metal Lathes Versus Wood Lathes During Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe isn’t level, it can make loud noises and cause accidents. This can break the machine or hurt you. For wood lathes, being way off can make the wood splinter or get stuck. Both situations are frustrating, and you might waste your materials. Always check the level first to keep everything safe!”}}]}