Imagine walking into a workshop filled with humming machines. The air buzzes with creativity and innovation. In this world, the lathe stands out as a key player. It’s a tool that shapes metal with amazing precision. But have you ever thought about how automation is changing this process?

Many people don’t realize how much precision metal lathes have advanced. These machines can now produce parts faster and more accurately. Automation takes away the guesswork. It allows the lathe to work round the clock, making it a game changer in manufacturing.

Did you know that some modern lathes can even operate on their own? This means fewer mistakes and less waste. Imagine getting the same high-quality result every time, without needing constant human help!

In this article, we will explore how lathe precision and automation go hand in hand. Join us as we take a closer look at how these machines shape the future of manufacturing.

Lathe Precision Metal Lathe Automation: Revolutionizing Machining

Lathe Precision Metal Lathe Automation

Precision metal lathes turn raw metal into amazing shapes. With automation, these machines become even smarter and faster. Imagine a robot that carves out parts while you relax! Automation makes the process more accurate and reduces mistakes. This technology also saves time and money, helping factories work better. Have you ever thought about how much easier your projects could be with this kind of help? Discovering automation in metal lathes opens up a world of possibilities!What is a Lathe?

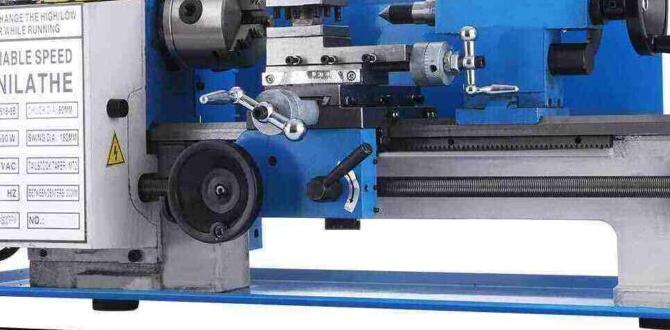

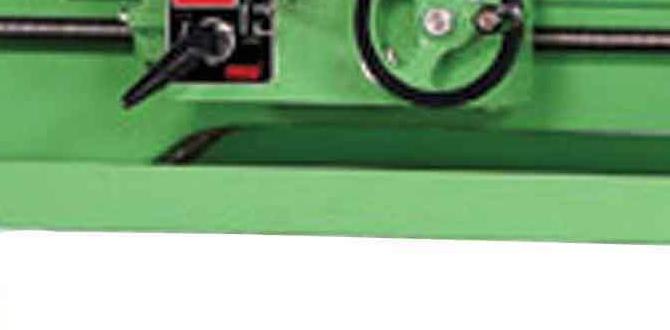

Definition and basic function of a lathe. Types of lathes used in metalworking.A lathe is a machine that spins material, like metal, to shape it into various objects. Imagine it as a giant pencil sharpener, but instead of wood, it grinds away metal! The main job of a lathe is to create smooth surfaces and precise parts. There are different types of lathes used in metalworking, such as the engine lathe, turret lathe, and CNC lathe. Each type helps in making everything from small screws to large gears.

| Type of Lathe | Best For |

|---|---|

| Engine Lathe | General purpose work |

| Turret Lathe | Mass production |

| CNC Lathe | High precision tasks |

The Importance of Precision in Metal Lathes

Definition of precision in machining processes. Impact of precision on product quality and manufacturing efficiency.Precision in machining means making parts that are exact and accurate. It affects how well products work and how easy they are to make. High precision creates better quality items and often reduces waste. This leads to faster production and lower costs. With lathe precision metal lathe automation, achieving this becomes easier.

- Better quality products

- Less waste or errors

- Faster production times

- Lower manufacturing costs

Why is precision important in metal lathes?

Precision is crucial because it affects product quality, efficiency, and costs. Accurate lathes make high-quality parts. This leads to happy customers and fewer mistakes.

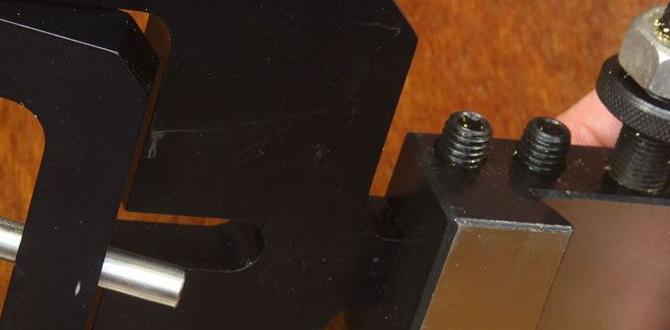

Key Components of a Precision Metal Lathe

Description of essential components (e.g., bed, headstock, tailstock). Role of each component in maintaining precision.A precision metal lathe is made up of several important parts. Each part plays a key role in making sure the machine works well. Here are some main components:

- Bed: The sturdy base that holds everything in place.

- Headstock: The front part where the motor turns the workpiece.

- Tailstock: The back part that helps support long materials during cutting.

All these parts work together. The bed keeps things stable, the headstock provides power, and the tailstock helps with balance. This balance allows the lathe to create precise shapes and sizes.

What is the role of the main components in a precision metal lathe?

The main components help ensure accuracy and smooth operation.

Advantages of Automating Precision Metal Lathes

Increased production speed and efficiency. Consistency in output quality.Automating precision metal lathes brings many benefits. One major advantage is increased production speed. Machines can work faster than humans, making more parts in less time. This helps companies meet demands quickly.

Another benefit is consistency in output quality. Automated lathes create the same part over and over with little error, reducing mistakes. This means higher quality products.

- Faster production times boost output.

- Uniform quality reduces rework and waste.

Overall, automation leads to a more efficient manufacturing process.

What are the benefits of automated lathes?

The benefits of automated lathes include faster production, consistent quality, and reduced labor costs. This technology helps factories run smoother and save money.

Challenges in Lathe Automation

Common obstacles faced in implementing automated systems. Solutions and technologies to overcome these challenges.Automating lathes can be tricky. Common challenges include high costs, complex setup, and training needs. Many companies face budget limits, making it hard to invest. Also, workers may need special training to use new technology. Solutions exist to tackle these problems. For example:

- Invest in affordable technology: Look for cost-effective automation tools.

- Provide training sessions: Help workers become skilled with new machines.

- Start small: Implement automation in phases to spread out costs.

With these steps, companies can enjoy the benefits of lathe automation while overcoming challenges.

What are the common challenges in lathe automation?

The main challenges are high initial costs, complex systems, and the need for specialized training.

Case Studies of Successful Lathe Automation

Realworld examples of businesses that improved their processes. Lessons learned and best practices.One company found success with lathe automation. They switched to a full automation system and saw a 30% increase in production speed. Workers were happy, and no one cried over spilled parts! Another business improved its workflow and reduced mistakes using automated precision lathes. They learned to train employees properly, leading to greater efficiency. Best practice? Start small, gather data, and grow. Here’s a quick glance at their achievements:

| Company | Improvement (%) | Lesson Learned |

|---|---|---|

| TechTurners | 30% | Train staff |

| MetalMakers | 25% | Start small |

These cases remind us that going automated can make work smoother! Simple changes can lead to big wins.

The Future of Lathe Precision and Automation

Emerging trends in lathe technology. Predicted developments in automation for the industry.The world of lathe technology is changing fast! We now see machines that use smart sensors. These sensors help improve lathe precision. They can detect problems before they happen, like a crystal ball for metalwork! Automation is also getting better. Soon, machines could work together without much help from humans. This means less time wasted and more time making cool stuff. Imagine robots chatting with each other while shaping metal—sounds like a sci-fi movie!

| Emerging Trends | Predicted Developments |

|---|---|

| Smart Sensors | Fully Automated Systems |

| Improved Precision Tools | Robotic Integration |

| Real-time Monitoring | Data-Driven Decisions |

Conclusion

In summary, lathe precision metal lathes are essential tools for creating accurate parts. Automation makes them faster and easier to use. You can produce high-quality products with less effort. Explore how these machines work and consider learning to operate one. Practical skills in metalworking can lead to exciting opportunities in various industries. Start your journey today!FAQs

What Are The Key Advantages Of Automating A Precision Metal Lathe In Manufacturing Processes?Automating a precision metal lathe means the machine works on its own. This helps us make parts faster and more accurately. You get the same high-quality results every time. It also saves us money because we need fewer people to run the machines. Plus, machines don’t get tired, so they can work all day long!

How Does The Integration Of Cnc Technology Enhance The Precision And Efficiency Of Metal Lathes?CNC technology, which stands for Computer Numerical Control, helps metal lathes work better. It allows the machine to follow precise plans made by a computer. This means we can create metal parts that fit perfectly every time. It also speeds things up, so we can make more parts in less time. Overall, CNC makes metal lathes smarter and faster!

What Types Of Automation Systems Are Commonly Used With Precision Metal Lathes, And How Do They Differ?There are a few types of automation systems used with precision metal lathes. One common type is called CNC, which stands for Computer Numerical Control. This system lets computers control the lathes so they can make very precise cuts. Another type is called robotic arms, which help move parts and tools around. CNC is great for detail, while robotic arms are good for moving heavy items quickly. Each system helps machines work better and faster in different ways.

What Are The Challenges And Considerations When Implementing Automation In A Manual Precision Metal Lathe Operation?When we bring machines to help with a manual metal lathe, we face some challenges. First, we need to make sure the new machines can do the same detailed work. Second, everyone working with the lathe must learn how to use the new tools safely. We also need to think about the costs of buying and maintaining these machines. Lastly, we should check that the machines fit well in our workspace and don’t cause any problems.

How Can Predictive Maintenance And Monitoring Technologies Improve The Uptime And Performance Of Automated Lathes In Production?Predictive maintenance and monitoring can help keep automated lathes running smoothly. By checking the machines often, we can find problems before they happen. This helps prevent breaks or stops. When lathes work better, they make more things faster. Overall, this means more time working and less time fixing!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Advantages Of Automating A Precision Metal Lathe In Manufacturing Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating a precision metal lathe means the machine works on its own. This helps us make parts faster and more accurately. You get the same high-quality results every time. It also saves us money because we need fewer people to run the machines. Plus, machines don’t get tired, so they can work all day long!”}},{“@type”: “Question”,”name”: “How Does The Integration Of Cnc Technology Enhance The Precision And Efficiency Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC technology, which stands for Computer Numerical Control, helps metal lathes work better. It allows the machine to follow precise plans made by a computer. This means we can create metal parts that fit perfectly every time. It also speeds things up, so we can make more parts in less time. Overall, CNC makes metal lathes smarter and faster!”}},{“@type”: “Question”,”name”: “What Types Of Automation Systems Are Commonly Used With Precision Metal Lathes, And How Do They Differ? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of automation systems used with precision metal lathes. One common type is called CNC, which stands for Computer Numerical Control. This system lets computers control the lathes so they can make very precise cuts. Another type is called robotic arms, which help move parts and tools around. CNC is great for detail, while robotic arms are good for moving heavy items quickly. Each system helps machines work better and faster in different ways.”}},{“@type”: “Question”,”name”: “What Are The Challenges And Considerations When Implementing Automation In A Manual Precision Metal Lathe Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we bring machines to help with a manual metal lathe, we face some challenges. First, we need to make sure the new machines can do the same detailed work. Second, everyone working with the lathe must learn how to use the new tools safely. We also need to think about the costs of buying and maintaining these machines. Lastly, we should check that the machines fit well in our workspace and don’t cause any problems.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance And Monitoring Technologies Improve The Uptime And Performance Of Automated Lathes In Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance and monitoring can help keep automated lathes running smoothly. By checking the machines often, we can find problems before they happen. This helps prevent breaks or stops. When lathes work better, they make more things faster. Overall, this means more time working and less time fixing!”}}]}