Have you ever wondered how some metal parts fit together perfectly? This magic often happens with a tool called a lathe. A lathe is a powerful machine. It helps shape metal into exact sizes and shapes. But not all lathes are the same.

The precision metal lathe bench stands out. It is designed for accuracy. This means it can make very small adjustments. Imagine you’re building a model car. You need parts that fit just right. A precision metal lathe can help you create those perfect pieces.

Did you know that precision lathes were first used hundreds of years ago? They have come a long way since then. Today, people use them in factories, workshops, and even at home. Whether you are a hobbyist or a professional, a lathe can be a game changer.

So, what can you make with a precision metal lathe bench? The possibilities are endless! From small gears to custom tools, each creation starts with a vision. Let’s explore how you can harness the power of this amazing tool.

Lathe Precision Metal Lathe Bench: Perfecting Your Craft

Lathe Precision Metal Lathe Bench

Precision metal lathes are key tools for many projects. They help create parts with exact measurements. Imagine designing a toy car and needing the wheels to fit perfectly. That’s where a precision lathe shines! Using a lathe bench allows you to work more efficiently. You can adjust the speed and settings for different materials. This flexibility leads to better results. Remember, the right lathe can boost your creativity and productivity in metalworking!Understanding the Basics of Bench Metal Lathes

Definition and function of a bench metal lathe. Key components and their roles in precision machining.A bench metal lathe is like a magic wand for metal! It spins metal pieces round and round, slicing them into perfect shapes. This tool is crucial for making parts in machines, cars, and even fancy robots. Key components include the headstock, which holds the motor and controls speed, and the tailstock, which supports the other end of the metal. Together, they help produce precise and smooth results, making every project a joy. It’s like having a tiny factory right on your bench!

| Component | Role |

|---|---|

| Headstock | Holds the motor and controls the speed of the lathe |

| Tailstock | Supports the metal piece and helps with drilling |

| Bed | Provides a stable base for precision machining |

| Carriage | Moves the cutting tool along the metal |

Key Features to Consider When Choosing a Lathe

Precision specifications and tolerances. Size, power, and speed considerations for your projects.Choosing a lathe requires understanding key features. First, precision specifications define how accurately the machine works. Look for machines that offer tight tolerances, ensuring quality results. Next, consider size, power, and speed. Bigger projects may need a larger lathe for better stability. Also, check the power. A more powerful machine can handle tougher materials. Finally, speed settings let you work at your pace. Different projects need different speeds for the best outcome.

What specifications should I look for in a lathe?

You should check the precision, size, power, and speed. These factors make sure your lathe can handle your projects well.

Key Points to Remember:

- Precision: Look for tight tolerances for quality.

- Size: Choose based on project needs.

- Power: More power handles tougher tasks.

- Speed: Adjustable speeds suit different projects.

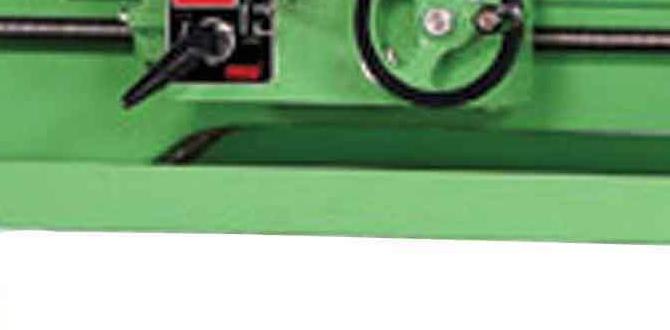

Setting Up Your Bench Lathe for Optimal Precision

Stepbystep guide to installation and leveling. Regular maintenance practices to ensure accuracy.To start strong, install your lathe on a sturdy workbench. Make sure it’s level. You can use a simple bubble level for this. Next, secure it tightly to prevent any wobbles—nobody wants a dancing lathe! For precision, check the alignment often. Do regular maintenance, like cleaning and oiling the moving parts. A clean lathe is a happy lathe! And remember, a great way to keep track is to make a maintenance schedule—like a gym plan, but for your tools!

| Maintenance Tasks | Frequency |

|---|---|

| Clean the lathe | Weekly |

| Oil moving parts | Monthly |

| Check alignment | Every use |

Techniques for Achieving High Precision in Metal Turning

Best practices for tool selection and handling. Tips for speed and feed rate adjustments for fine finishes.Choosing the right tools is like picking the best snacks for movie night. You want what works! Good cutting tools can make all the difference in getting precise cuts. Handling them with care is key, too. If you give them a little love and attention, they will perform better. Don’t forget to adjust the speed and feed rates. A slower feed might help achieve shiny finishes, just like how slow-cooked meals taste better. See the table below for quick tips!

| Tool Selection | Feed Rate Adjustment |

|---|---|

| Choose sharp, high-quality tools. | Start with a lower feed rate for finishing. |

| Use materials designed for your lathe. | Gradually increase speed for better results. |

Remember, great precision in metal turning is like finding that perfect pizza slice. It takes a bit of effort, but the reward is delicious!

Common Challenges and Solutions in Lathe Operations

Identifying and troubleshooting precision issues. Strategies for overcoming common machining problems.Many problems can arise during lathe operations. Identifying these issues early is crucial. Common precision problems include uneven cuts and vibrations. To fix these, check the sharpness of the tools and the alignment of the workpiece. Here are some quick tips to troubleshoot:

- Keep tools sharp for smooth cuts.

- Ensure the workpiece is tightly secured.

- Adjust lathe speed according to material type.

By addressing these challenges, you can achieve better results with your lathe precision metal lathe bench.

What are some common issues when using a lathe?

Common lathe issues include chatter, tool wear, and poor surface finish. Regular maintenance and proper setup can help avoid these problems.

Safety Best Practices When Operating a Metal Lathe

Essential safety equipment and gear. Key safety protocols to prevent accidents and injuries.Using a metal lathe can be fun but also risky. Always wear essential safety gear for protection. This includes safety goggles, gloves, and a dust mask. Follow these key safety protocols to avoid accidents:

- Keep hands away from moving parts.

- Check that all tools are secure before starting.

- Never leave the lathe running unattended.

- Keep the workspace clean and organized.

Taking these steps can help create a safer environment. Always stay alert and focused while you work!

What safety gear do you need for a metal lathe?

Essential gear includes safety goggles, gloves, and a dust mask. This gear keeps you safe from flying debris and harmful particles.

Advanced Tips for Experienced Lathe Operators

Techniques for advanced machining and custom work. Innovations in lathe technology to watch for in the future.Have you ever thought about making your lathe work more amazing? Advanced techniques can help you create custom parts like a wizard with a magic wand! Special tools like insert tool holders and live tooling can boost your machining skills. Plus, new tech is on the horizon, like AI-powered lathes that will make your projects even cooler! Keep an eye out; these innovations could make you the star of the workshop.

| Technique | Benefit |

|---|---|

| Insert Tool Holders | Allows quick changes and less downtime! |

| Live Tooling | Enables milling and turning in one go! |

| AI Features | Turns you into a machining superhero! |

Conclusion

In summary, a precision metal lathe bench is essential for accurate metal crafts. It helps you shape and cut metal with ease. You get better results and save time. If you want to enhance your skills, consider getting one. Dive deeper into tutorials or guides to learn more about using a lathe effectively. Start your metalworking journey today!FAQs

What Are The Key Features To Look For In A Precision Metal Lathe For A Professional Workshop?When you look for a good metal lathe, check its size first. A bigger lathe can handle larger pieces. Then, make sure it has a strong motor. A strong motor helps you work faster and more smoothly. Lastly, look for easy controls. Simple buttons make it easier for you to use the lathe.

How Do The Specifications Of A Bench Lathe Affect Its Performance In Precision Metalworking Tasks?The specifications of a bench lathe are important for how well it works. For example, the size of the lathe helps you make bigger or smaller items. The speed controls lets you work faster or slower, which helps in being precise. If the lathe is sturdy, it won’t shake, which keeps your work accurate. Good specifications help us make better metal parts in our projects.

What Maintenance Practices Are Essential For Ensuring The Accuracy And Longevity Of A Precision Metal Lathe?To keep a precision metal lathe working well, we need to clean it regularly. Dust and chips can get stuck, so we should wipe them away. We also need to check the oil levels and add oil to keep parts moving smoothly. Tightening loose screws helps everything stay in place. Finally, we should look for any signs of wear and fix them right away.

How Can I Improve My Turning Techniques To Achieve Higher Precision With A Bench Lathe?To improve your turning techniques on a bench lathe, you should practice regularly. Keep your tools sharp and clean for better cuts. Use a steady hand and gentle pressure when guiding the tool. Check your measurements often to make sure they are right. Finally, watch videos or ask someone experienced for tips!

What Are The Differences Between Cnc Lathes And Traditional Bench Lathes In Terms Of Precision And Usability?CNC lathes use computers to control their movements, making them very precise. You can create complex shapes easily with them. Traditional bench lathes require more hands-on skill and can be less exact. They are great for simple jobs but need you to be more careful. So, CNC lathes are easier for tricky tasks, while traditional lathes need more practice.