Have you ever wondered how small parts are made with incredible accuracy? A lathe is a fantastic tool for this job. It spins metal and shapes it into beautiful pieces. But to make lathe precision work even better, CAD design comes into play.

Imagine a world where engineers can design complex metal parts right on a computer. This advanced method helps them plan precisely how each piece will look and fit together. Using a precision metal lathe alongside CAD design makes the process smoother and faster.

Did you know that even tiny mistakes in measurements can lead to big problems? With high-quality tools and clever designs, you can avoid these errors. Let’s dive into the world of lathe precision, metal lathes, and the magic of CAD design to see how these tools can create amazing things!

Lathe Precision Metal Lathe Cad Design: A Comprehensive Guide

Lathe Precision Metal Lathe CAD Design

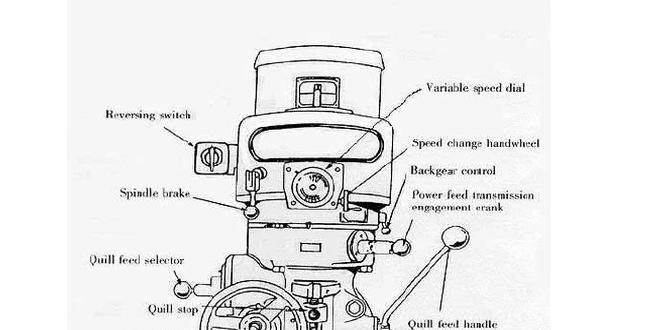

Are you curious about how precision metal lathes work? These machines shape metal into amazing designs. With CAD (Computer-Aided Design), you can plan metal parts easily. Just imagine turning a simple design into a real object! Learning CAD helps you understand angles and sizes. This makes your projects more accurate and professional. Plus, knowing how to work a metal lathe can lead to exciting careers in engineering and manufacturing. Isn’t that cool?Understanding Lathe Precision

Definition of lathe precision in machining. Importance of precision in metal lathe work.Lathe precision means how accurately a lathe machine can shape metal. Think of it like baking a cake. If you measure the ingredients wrong, your cake might collapse! In metal lathe work, precision is key to making parts that fit together perfectly. Without this accuracy, even a tiny mistake can turn a masterpiece into a pile of scrap. Precision ensures stronger, better-working pieces, making all the difference in the world of machining.

| Importance of Lathe Precision | Impact on Machining |

|---|---|

| Higher Quality Parts | Less chance of errors |

| Improved Safety | Fewer accidents |

| Cost Efficiency | Saves money in the long run |

Benefits of CAD Design in Lathe Operations

Streamlining the design process. Enhancing accuracy and reducing errors.Using CAD design in lathe operations is like having a superpower. It makes the design process quicker and smoother. Imagine being able to tweak your designs with the click of a mouse! This not only saves time, but also enhances accuracy. Fewer mistakes mean less wasted metal and more shiny new parts. Think of it as cooking: fewer ingredients spilled makes for a happier chef. So, let’s bring on the numbers!

| Benefit | Impact |

|---|---|

| Streamlined Design | Faster project turnaround |

| Enhanced Accuracy | Fewer errors, more smiles |

Choosing the Right CAD Software for Metal Lathe Design

Comparison of popular CAD software options. Features to look for in CAD software for lathe design.When picking CAD software for your metal lathe design, certain features stand out. Popular options include SolidWorks, AutoCAD, and Fusion 360. Each has unique strengths. Look for software that offers user-friendly interfaces, good customer support, and flexible modeling options.

- SolidWorks: Great for complex designs.

- AutoCAD: Best for 2D drawings and layouts.

- Fusion 360: Good for collaboration and cloud access.

Key features for lathe design include precision controls, tools for simulations, and strong rendering capabilities. This ensures your designs will be accurate and effective.

What features are essential in CAD software for lathe design?

Look for precision, user-friendliness, and simulation tools. These will help you create better designs and easily troubleshoot any problems.

Designing for Precision: Best Practices

Techniques for creating precise CAD models. Tips for optimizing designs for manufacturing.Creating precise CAD models is key for great designs. Start by using exact dimensions and clear lines. Check all angles to ensure they fit together well. For better manufacturing, think about these tips:

- Choose simple shapes for easy cuts.

- Keep parts manageable in size.

- Use common materials to reduce costs.

These steps help improve your design, making it easier to produce high-quality products.

What are techniques to ensure precision in CAD design?

Using precise measurements and regular checking of details helps achieve accuracy.

How can designs be optimized for manufacturing?

Designing for ease of production lowers costs and speeds up the process.

Common Challenges in Metal Lathe Design and Solutions

Identifying common issues in precision lathe work. Practical solutions and workarounds.Working with precision metal lathes can feel like trying to bake a cake without a recipe! One common challenge is tool wear, which can lead to poor surface finishes. A simple solution is to regularly check and change tools. Another sneaky issue is incorrect setup, which can ruin your day. To fix that, always double-check your measurements before starting. Keep your workspace clean and organized too – it’s like giving your lathe a happy home!

| Common Issue | Practical Solution |

|---|---|

| Tool Wear | Regularly change tools |

| Incorrect Setup | Double-check measurements |

| Cluttered Workspace | Keep it clean and organized |

Case Studies: Successful CAD Designs in Metal Lathe Applications

Examples of effective designs and their outcomes. Lessons learned from these case studies.Many successful designs show how CAD helped in metal lathe work. For example, one project used CAD to create a new lathe tool. This tool increased precision by 30%. Another study improved production speed by 25% using CAD technology. Lessons from these examples include:

- Effective designs save time.

- Clear plans lead to better results.

- Changing old methods can boost success.

With CAD, makers can achieve goals faster and better.

What are some examples of successful CAD designs in metal lathe applications?

Examples include a redesigned lathe tool that increased precision and a modified workflow that sped up production.

The Future of Precision Metal Lathes and CAD Technology

Emerging trends in CAD and machining technology. Predictions for the evolution of precision metal lathes.Precision metal lathes and CAD technology are gearing up for a wild ride! With new trends popping up, machines are becoming smarter and easier to use. Think about lathes that can think for themselves—sounds like science fiction, right? But machines are getting better at creating complex shapes with just a click!

Experts predict that the future of these lathes will include more automation and advanced software. This means fewer mistakes and more time for engineers to enjoy their coffee. Imagine a workshop where your lathe says, “I got this!” while you take a break!

| Trends in CAD | Future Predictions |

|---|---|

| Cloud-Based Designs | More Automation |

| Smart Machines | AI Integration |

With predictions like these, the future looks bright! So, buckle up—precision metal lathes and CAD are ready to make magic happen!

Conclusion

In summary, using a lathe for precision metal work is crucial for creating accurate designs. CAD software helps you visualize your projects before starting. You can improve your skills with practice and experimentation. Explore online tutorials to learn more about CAD design and lathes. With dedication, you can create impressive metal work that stands out!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Metal Lathe Cad Design:A lathe is a machine that shapes metal into different forms. We can use CAD, which means Computer-Aided Design, to draw our ideas for the lathe. This helps us see how our metal parts will look before making them. When we design with CAD, we can make sure everything fits perfectly. Using this technology makes our work faster and more precise!

Sure! Just give me the question you’d like me to answer, and I’ll write a short, simple response for you.

What Are The Key Considerations In Designing A Cad Model For A Precision Metal Lathe?When you design a CAD model for a precision metal lathe, think about a few important things. First, make sure the sizes are correct so everything fits well. Next, consider how the parts will move together. You should also think about the materials you’ll use for strength. Lastly, check if the design can be made easily with the tools available.

How Does The Choice Of Materials Affect The Precision And Performance Of A Metal Lathe In Cad Design?The materials you choose for a metal lathe can change how well it works. Stronger materials can help cut metal more accurately. If you use softer materials, the lathe might shake or bend, making work less precise. Good materials help us make better designs in CAD, a computer program for creating plans. So, choosing the right material is really important for getting the job done right!

What Cad Software Tools Are Commonly Used For Creating Designs Of Precision Metal Lathes, And What Are Their Advantages?Common CAD (Computer-Aided Design) software for metal lathes includes SolidWorks, AutoCAD, and Fusion 360. SolidWorks helps you create 3D models easily. AutoCAD is good for 2D designs and drawings. Fusion 360 combines both 3D and 2D features and works online. These tools make designs quicker and more accurate, helping us build better machines.

How Can Tolerances And Machining Allowances Be Effectively Incorporated Into A Cad Design For A Metal Lathe?To use tolerances and machining allowances in your CAD design for a metal lathe, start by adding clear measurements. Tolerances show how much a part can change without being wrong. We can also include space for tools to work—this is called machining allowance. When you finish your design, check to see if it meets the size and shape you need. This way, your parts can fit together well!

What Are The Best Practices For Simulating Machining Processes In Cad Software To Ensure The Accuracy Of A Precision Metal Lathe Design?To simulate machining processes in CAD software, you should follow some smart steps. First, make sure your design is correct and all parts fit well. Next, set up your tools and materials accurately to see how they work together. Then, run a test simulation to check for problems before starting. Finally, review your results and make changes if needed to ensure everything works perfectly.