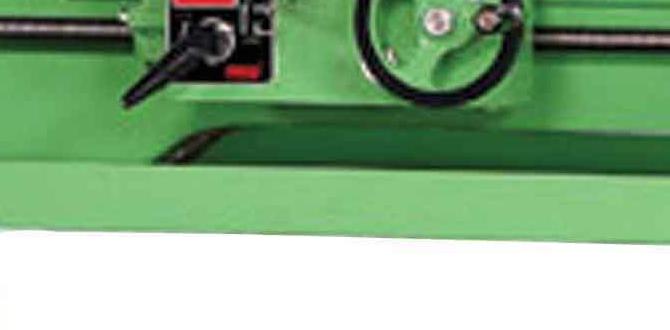

Imagine working in a workshop. You’re surrounded by buzzing machines and shiny metal parts. Exciting, right? In this world, precision is key. That’s where the lathe comes in.

A lathe is a fantastic machine. It helps shape metal into all kinds of useful things. But did you know that a small tool called a chuck key is vital for this process? It might look simple, but it holds great importance.

Using a lathe without a precision metal lathe chuck key is like trying to bake without a spoon. It just doesn’t work well! The chuck key tightens and loosens the metal pieces on the lathe. This exactness ensures everything spins smoothly. Without it, projects can go wrong.

Curious to learn more? Let’s dive into the fascinating world of lathe machines and discover why the chuck key is a must-have for any metal worker!

Lathe Precision Metal Lathe Chuck Key: Essential Tools Insights

Lathe Precision Metal Lathe Chuck Key

A lathe precision metal lathe chuck key is essential for securely tightening and loosening workpieces. This small yet vital tool allows for precise adjustments. Imagine trying to balance a small toy on a spinning plate; without the right grip, it falls! Similarly, the chuck key ensures your metal piece stays in place. Understanding its proper use can improve accuracy in your projects. Engage with this tool, and you’ll see how it enhances your metalworking skills!What is a Metal Lathe and Its Applications?

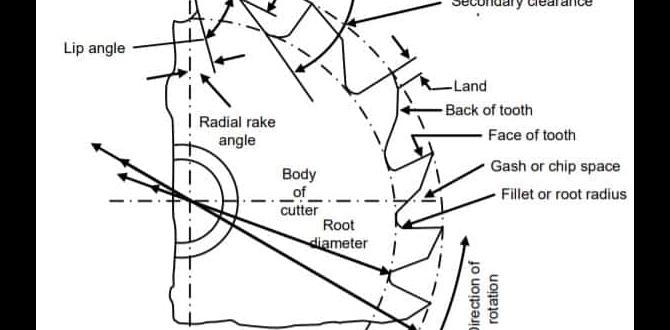

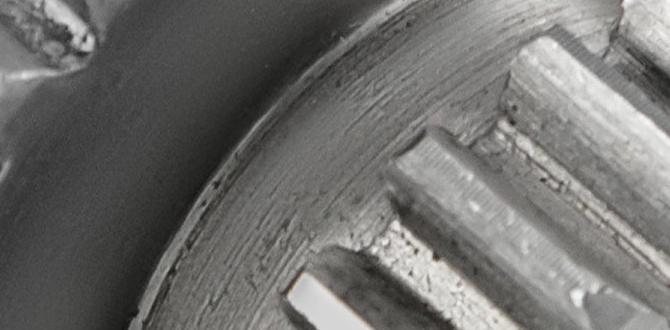

Definition and purpose of metal lathes.. Common industries and projects utilizing metal lathes..A metal lathe is a special machine that shapes metal into different forms. Think of it as a giant, spinning cookie cutter for metal! These lathes cut, drill, and sometimes even sand metals to make precise parts for many projects.

They are heroes in industries like manufacturing, aerospace, and automotive. Whether it’s making a gear for a spaceship or crafting a fancy metal knob, metal lathes are everywhere! They help create things we use daily, like car parts, tools, and even art. So, remember, next time you see a shiny metal part, a lathe probably had a hand in making it!

| Industry | Application |

|---|---|

| Aerospace | Parts for airplanes |

| Automotive | Engine components |

| Manufacturing | Machinery parts |

How to Choose the Right Chuck Key for Your Lathe

Factors to consider when selecting a chuck key.. Importance of compatibility with lathe models..Choosing the right chuck key is important for good work on your lathe. Start by thinking about size and shape. They must fit tightly. Next, check compatibility with your lathe model. Not all keys match all lathes. A few factors to consider are:

- Chuck size

- Key type

- Material quality

Getting the right chuck key can make your tasks easier. It helps keep everything secure while you work. So, don’t rush when picking one!

What is the importance of compatibility with lathe models?

Compatibility directly affects performance. Using the right chuck key ensures a snug fit. This prevents slips and accidents, leading to safer and cleaner work.

Benefits of Using a Precision Chuck Key

Advantages of precision in metalworking.. How a quality chuck key enhances machining accuracy..Using a precision chuck key in metalworking brings many benefits. It helps keep tools tight, which improves the quality of parts. This means less wasted material and time. A good chuck key makes sure everything runs smoothly. Here are some advantages:

- Increased accuracy: A precise fit leads to better measurements.

- Less vibration: Keeps machines steady for cleaner cuts.

- Longer tool life: Reduces wear and tear on machines.

These advantages show why choosing a quality chuck key is important for successful machining.

Why is precision important in metalworking?

Precision leads to better quality and efficiency. Parts made with care fit together tightly. This results in longer-lasting products.

Maintenance Tips for Lathe Chuck Keys

Basic care practices for longevity and performance.. Common issues and troubleshooting methods..To keep your lathe chuck key in top shape, follow some simple care tips. Always clean the key after use. This prevents dirt build-up that can cause problems. Store it in a safe place, away from moisture. Regular checking for wear and tear helps catch issues early. Common problems include difficulty in turning or rust. If you face these, apply some oil or use a wire brush. Your lathe chuck key will thank you!

What are basic care practices for a lathe chuck key?

Basic care practices for a lathe chuck key include cleaning, proper storage, and routine inspections. By following these steps, you enhance its longevity and performance.

Key Tips:

- Clean after each use

- Store in a dry place

- Inspect regularly for wear

Common Mistakes to Avoid When Using Chuck Keys

Frequent errors that can lead to damage or injury.. Best practices for safe and effective usage..Using chuck keys can be tricky! Many folks make easy mistakes that can cause damage or, worse, lead to injuries. First, never forget to remove the key from the chuck before starting the machine—it’s a major safety “oops.” Always check that your key fits snugly and is in good shape; a worn key is like a superhero without its cape! For best results, hold the key firmly and apply even pressure. Here’s a handy table to keep in mind:

| Error to Avoid | Best Practice |

|---|---|

| Starting the machine with the key in | Always remove the key first |

| Using a damaged chuck key | Inspect for wear and tear before use |

| Pushing too hard with the key | Apply steady and even pressure |

By following these tips, you’ll not only work safer but also feel like a lathe master!

Future Trends in Metal Lathe Technology

Innovations and advancements in lathe technology.. Predictions for the future of lathe precision and chuck design..New ideas are changing the way we think about metal lathes. Technology keeps getting better. Some exciting trends include:

- Smart lathes that use sensors.

- Robotic arms for precision work.

- New materials to make chucks stronger.

In the future, we may see chucks that self-adjust for better fit. This will make the work faster and safer. Experts believe that these advancements will increase accuracy up to 50% over the next decade. These improvements will help lathes become even more useful in workshops.

What are the predictions for the future of lathe technology?

Future lathe technology will focus on greater precision, efficiency, and user-friendliness. Innovations like advanced automated systems and AI will help craftsmen achieve top-notch results.

Conclusion

In summary, a lathe precision metal lathe chuck key is essential for your machining projects. It helps securely hold metal pieces in place. This ensures accuracy and safety while you work. Remember to choose the right size key for your lathe. You can explore more about lathe usage and maintenance to improve your skills and knowledge. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Metal Lathe Chuck Keys:Sure! A lathe is a tool that spins metal or wood to shape it. A chuck key helps you tighten or loosen the chuck, which holds the material. Using the right chuck key is important for keeping everything safe and working well. If you lose your chuck key, you might not be able to use the lathe properly. Always keep it in a special spot so you can find it easily!

Sure! Please provide me with the question you want answered.

What Are The Different Types Of Chuck Keys Available For Precision Metal Lathes, And How Do They Affect Clamping Accuracy?There are a few types of chuck keys for metal lathes. The most common ones are T-handle, wheel, and pin-type keys. T-handle keys help you grip better and turn easily. Wheel keys let you spin faster. Each type helps hold parts tightly, so they don’t move or slip when you cut or shape metal. Good clamping makes your work more accurate.

How Do You Choose The Right Size And Style Of Chuck Key For Your Specific Lathe Model?To pick the right size and style of chuck key for your lathe, first check your lathe’s manual. It usually tells you the size you need. Next, look at the chuck key you have or find one at a store that fits. You need a key that fits snugly so you can tighten and loosen things easily. Always be sure it matches your lathe’s design.

What Are The Common Maintenance Practices For Lathe Chuck Keys To Ensure Optimal Performance And Longevity?To keep lathe chuck keys working well, you should clean them regularly. Use a cloth to wipe off dirt and oil. Check for any damage or wear. If you see any, replace the key. Store it in a safe, dry place to avoid losing it.

How Does The Design Of A Chuck Key Influence The Ease Of Use And Safety During Lathe Operations?The design of a chuck key makes it easier to use and safer when you work on a lathe. If the key fits well, you can tighten or loosen things without struggling. A good design also keeps your hands safe from the moving parts. Plus, some keys have handles that give you a better grip. This way, you can work quickly and stay safe!

What Are The Potential Issues That Can Arise From Using An Incorrect Or Worn-Out Chuck Key On A Precision Metal Lathe?Using the wrong or old chuck key on a metal lathe can cause big problems. It might not hold the tools tightly, which can make them slip. When they slip, your work can be ruined and might even hurt you. Also, using the wrong size can damage the lathe itself. Always check your chuck key to keep everything safe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Metal Lathe Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that spins metal or wood to shape it. A chuck key helps you tighten or loosen the chuck, which holds the material. Using the right chuck key is important for keeping everything safe and working well. If you lose your chuck key, you might not be able to use the lathe properly. Always keep it in a special spot so you can find it easily!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Chuck Keys Available For Precision Metal Lathes, And How Do They Affect Clamping Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of chuck keys for metal lathes. The most common ones are T-handle, wheel, and pin-type keys. T-handle keys help you grip better and turn easily. Wheel keys let you spin faster. Each type helps hold parts tightly, so they don’t move or slip when you cut or shape metal. Good clamping makes your work more accurate.”}},{“@type”: “Question”,”name”: “How Do You Choose The Right Size And Style Of Chuck Key For Your Specific Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right size and style of chuck key for your lathe, first check your lathe’s manual. It usually tells you the size you need. Next, look at the chuck key you have or find one at a store that fits. You need a key that fits snugly so you can tighten and loosen things easily. Always be sure it matches your lathe’s design.”}},{“@type”: “Question”,”name”: “What Are The Common Maintenance Practices For Lathe Chuck Keys To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe chuck keys working well, you should clean them regularly. Use a cloth to wipe off dirt and oil. Check for any damage or wear. If you see any, replace the key. Store it in a safe, dry place to avoid losing it.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Chuck Key Influence The Ease Of Use And Safety During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a chuck key makes it easier to use and safer when you work on a lathe. If the key fits well, you can tighten or loosen things without struggling. A good design also keeps your hands safe from the moving parts. Plus, some keys have handles that give you a better grip. This way, you can work quickly and stay safe!”}},{“@type”: “Question”,”name”: “What Are The Potential Issues That Can Arise From Using An Incorrect Or Worn-Out Chuck Key On A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the wrong or old chuck key on a metal lathe can cause big problems. It might not hold the tools tightly, which can make them slip. When they slip, your work can be ruined and might even hurt you. Also, using the wrong size can damage the lathe itself. Always check your chuck key to keep everything safe.”}}]}