Have you ever wondered how metal parts are made with precision? It’s fascinating, isn’t it? One tool that helps craftsmen achieve this is the lathe. Many people might think a lathe is just a machine, but it’s much more than that. It allows for fine-tuning and detailed work on metal pieces. Imagine being able to create parts that fit perfectly every time!

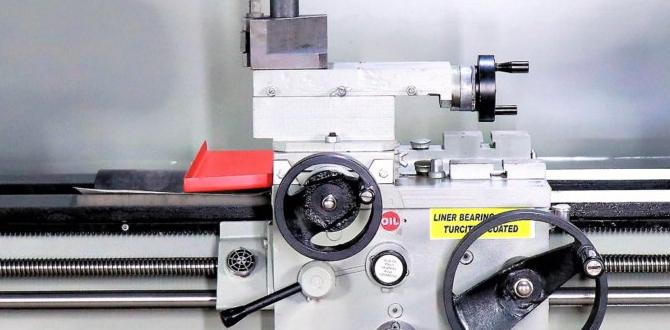

One crucial part of a lathe is the compound rest. This small but mighty component helps position the tool at the exact angle needed for each cut. Without it, achieving precision can be a tough challenge. Have you ever tried to draw a straight line without a ruler? It can be tricky! The same goes for metalwork.

In this article, we will explore how the lathe and its compound rest work together to create amazing metal pieces. Get ready to dive into the world of lathes and discover the magic of precision! Who knows? You might just want to try it yourself!

Lathe Precision Metal Lathe Compound Rest: A Guide

Lathe Precision Metal Lathe Compound Rest

Want to make accurate cuts on a metal lathe? The compound rest is key. It allows you to adjust the cutting angle easily, helping you create precise shapes. This part can slide along the lathe bed, giving you more control. Did you know that a well-set compound rest can improve your work quality significantly? Learning how to use it can seem tricky, but practice makes perfect. It’s a crucial tool for any metalworking enthusiast!Understanding the Basics of Precision Metal Lathes

Definition and function of a precision metal lathe. Importance of precision in metalworking applications.A precision metal lathe is a machine tool that shapes metal into precise designs. It does this by turning the metal while cutting tools remove material, creating shapes like cylinders or spheres. Precision is crucial in metalworking because even a tiny mistake can lead to big problems. When parts don’t fit together, it’s like trying to put a square peg in a round hole! So, a precision lathe helps ensure the perfect fit, making your projects smoother and more fun.

| Feature | Description |

|---|---|

| Definition | A machine that turns metal to create accurate shapes. |

| Function | Removes material from rotating metal for desired shapes. |

| Importance | Ensures parts fit together without issues. |

The Purpose and Benefits of the Compound Rest

Description of the compound rest and its positioning on the lathe. Advantages of using a compound rest for accuracy and versatility.A compound rest is a vital part of a lathe. It holds the cutting tool and allows for precise adjustments. Positioned above the cross slide, it enables angles and depths of cuts easily.

Using a compound rest has many advantages:

- Improved accuracy for detailed work.

- Greater versatility in cutting angles.

- Ease of setup for different projects.

With a compound rest, you can make difficult cuts effortlessly. This simple tool can make challenging tasks feel easy!

What is the importance of the compound rest in a lathe?

The compound rest is crucial for precision. It allows for easy adjustments to achieve accurate and intricate designs.

How to Properly Set Up the Compound Rest

Stepbystep guide on adjusting the compound rest for optimal performance. Common mistakes to avoid during setup.Setting up the compound rest correctly is key for precision. Here’s how to do it:

- First, clean the area where you will work.

- Next, loosen the adjusting screws slightly.

- Align the compound rest with the lathe bed.

- Tighten the screws securely.

- Finally, test the movement to ensure it’s smooth.

Avoid these mistakes:

- Don’t skip cleaning first.

- Don’t overtighten the screws.

- Don’t forget to check if it moves freely.

These steps and tips will help you achieve the best results!

How do you use the compound rest on a lathe?

To use the compound rest, simply adjust it to the angle you need for cutting. This helps get precise shapes and sizes.

Common Adjustments:

- Set it at a 30-degree angle.

- Use the handle to guide the tool.

Techniques for Using the Compound Rest Effectively

Various machining techniques that leverage the compound rest for enhanced precision. Tips for ensuring consistent results in turning operations.The compound rest is a tool that can improve your work with precision. Here are some effective techniques:

- Adjust the angle for better cutting.

- Use light cuts to avoid mistakes.

- Check your measurements often to stay accurate.

- Keep your tools sharp for the best results.

- Practice different speeds for a smooth finish.

For consistent results while turning, remember these tips:

- Be patient and take your time.

- Setup everything carefully before starting.

- Double-check your settings before each cut.

How can I improve my cutting precision with a compound rest?

To improve cutting precision, ensure your lathe is stable. Regularly check and adjust the settings for each job. It’s like tuning a guitar; you want everything just right for the best sound, or in this case, the best cut!

Maintenance Tips for Ensuring Longevity of the Compound Rest

Routine maintenance practices to keep the compound rest in top condition. Troubleshooting common issues related to the compound rest.Keeping your compound rest in shape is like feeding a pet; it needs regular care! Start by cleaning it often, removing dirt and grime. This keeps it smooth and happy. You’re avoiding trouble, right? Check for rust or wear since those are sneaky problems! For quick fixes, tighten loose bolts and ensure everything moves fluidly. Remember, a little oil never hurts—like giving your lathe a spa day!

Here are some common issues and solutions:

| Problem | Solution |

|---|---|

| Stiff movement | Check for debris and lubricate |

| Rust spots | Use rust remover and oil regularly |

| Uneven cuts | Ensure components are aligned properly |

Follow these tips, and your compound rest will last longer than a childhood toy that can’t get broken. Happy turning!

Comparing Different Types of Compound Rests

Discussion of various compound rest designs and their unique features. Pros and cons of each type for specific metalworking tasks.Compound rests are key tools in metalworking. Each design has its own features, which help in different tasks. Here’s a quick look at some popular types:

- Flat Compound Rest: Simple design. Good for basic tasks. However, it might not support large pieces well.

- Swivel Compound Rest: Can rotate smoothly. Great for angles. But can be tricky to set up.

- Powered Compound Rest: Offers more control with electric power. Excellent for repeat jobs. Yet, it may need more maintenance.

Choosing the right design helps you work better. The best one depends on your specific needs.

What should I consider when choosing a compound rest?

Think about your project needs, space available, and budget. These factors will guide your choice.

Case Studies: Compound Rest Applications in Precision Machining

Realworld examples of projects utilizing the compound rest effectively. Analysis of results achieved through proper compound rest usage.In the world of precision machining, the compound rest is like the superhero of lathes. Take a small project, like making custom knobs for gadgets. By adjusting the compound rest, machinists achieve amazing angles. This leads to perfect fitting knobs that make gadgets shine.

Another great example is in creating specialized gears. Using the compound rest, machinists can precisely cut teeth. This results in gears that mesh seamlessly. Who knew metal could be that charming?

Check out this table showing some fun project stats:

| Project | Angles Achieved | Success Rate (%) |

|---|---|---|

| Custom Knobs | 30° – 45° | 98 |

| Specialized Gears | 15° – 60° | 95 |

These projects prove that the compound rest can turn simple metal into masterpieces. With the right setup, the sky is the limit!

Future Trends in Lathe Technology and Precision Machining

Innovations influencing the design and functionality of compound rests. Predictions for the evolution of precision metal lathes in the coming years.New technologies are changing how we make things. Compound rests in lathes are becoming smarter. They now have digital controls, which make them easier to use. These updates help workers create parts more accurately. In the future, we can expect:

- More automation for faster production.

- Better software for designing metal parts.

- Sensors that can catch errors before they happen.

The precision metal lathe will evolve rapidly. Experts predict that in just a few years, lathes will be lighter and more efficient. With fewer mistakes, businesses can save money and time.

How is technology changing lathes?

Technology is adding new features, like smart controls and sensors, to make lathes work better. These changes help builders create high-quality parts faster.

Conclusion

In conclusion, a lathe with a precision metal lathe compound rest gives you accuracy and control. This tool helps make detailed parts easily. By using the compound rest correctly, you can improve your projects significantly. We encourage you to explore more about lathes and practice using them. Understanding these tools will boost your skills and confidence in metalworking!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Metal Lathe Compound Rest:Sure! A lathe is a machine that shapes metal. The compound rest helps you move the tool in different directions. This makes it easier to cut shapes. You can change the angle for better cuts. It helps us make things like screws or parts for toys!

Sure! Just let me know what question you want me to answer!

What Is The Function Of The Compound Rest In A Precision Metal Lathe?The compound rest is part of a precision metal lathe. It helps you move the cutting tool at different angles. This way, you can make special shapes and cut more carefully. You can adjust it easily to get the exact angle you want. It makes your work more precise and smoother.

How Do You Properly Align And Adjust The Compound Rest For Precise Machining?To align and adjust the compound rest, first, make sure the machine is off. Next, check that the compound rest is level. You can do this by using a small level tool. Then, loosen the adjustment screws slightly and move the rest until it’s just right. Finally, tighten the screws to hold it in place.

What Are The Key Differences Between A Standard Compound Rest And A Swivel Compound Rest?A standard compound rest can only move up and down or side to side. A swivel compound rest can rotate in different directions. This helps you make better cuts from different angles. You can use both, but the swivel one is more flexible. This means it’s often easier to work with.

How Can The Design Of The Compound Rest Influence The Accuracy And Surface Finish Of Machined Parts?The compound rest is an important part of a machine that holds tools. If it’s designed well, it helps you cut and shape materials more accurately. A good design keeps the tool steady, so you get smoother surfaces. When the tool moves smoothly, your finished parts look better and fit together nicely. So, a good compound rest makes your work easier and improves your results!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Precision Of A Metal Lathe’S Compound Rest?To keep a metal lathe’s compound rest working well, you should clean it regularly. Use a soft cloth to wipe away dust and chips. Apply a little oil to the moving parts. This helps them move smoothly. Check for any loose screws and tighten them if needed.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal. The compound rest helps you move the tool in different directions. This makes it easier to cut shapes. You can change the angle for better cuts. It helps us make things like screws or parts for toys!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer!”}},{“@type”: “Question”,”name”: “What Is The Function Of The Compound Rest In A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest is part of a precision metal lathe. It helps you move the cutting tool at different angles. This way, you can make special shapes and cut more carefully. You can adjust it easily to get the exact angle you want. It makes your work more precise and smoother.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Adjust The Compound Rest For Precise Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust the compound rest, first, make sure the machine is off. Next, check that the compound rest is level. You can do this by using a small level tool. Then, loosen the adjustment screws slightly and move the rest until it’s just right. Finally, tighten the screws to hold it in place.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between A Standard Compound Rest And A Swivel Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A standard compound rest can only move up and down or side to side. A swivel compound rest can rotate in different directions. This helps you make better cuts from different angles. You can use both, but the swivel one is more flexible. This means it’s often easier to work with.”}},{“@type”: “Question”,”name”: “How Can The Design Of The Compound Rest Influence The Accuracy And Surface Finish Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest is an important part of a machine that holds tools. If it’s designed well, it helps you cut and shape materials more accurately. A good design keeps the tool steady, so you get smoother surfaces. When the tool moves smoothly, your finished parts look better and fit together nicely. So, a good compound rest makes your work easier and improves your results!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Precision Of A Metal Lathe’S Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe’s compound rest working well, you should clean it regularly. Use a soft cloth to wipe away dust and chips. Apply a little oil to the moving parts. This helps them move smoothly. Check for any loose screws and tighten them if needed.”}}]}