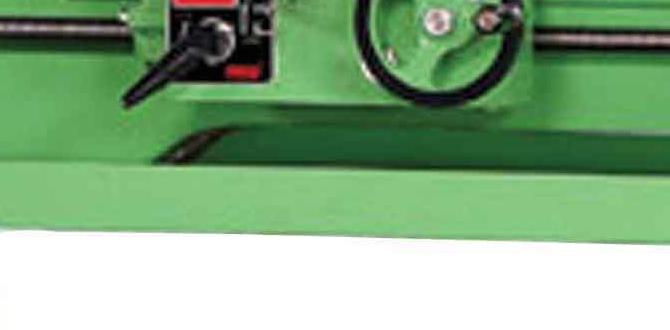

Have you ever wondered how metal lathes work? These amazing machines shape metal into useful tools and art. A key part of their function is the gear train. The gear train helps control speed and movement, making lathes work like magic.

Lathe rebuilding can feel tricky, but it is very rewarding. Imagine fixing up an old machine to make it run better than ever. That’s the power of knowledge! A well-maintained gear train can extend the life of your lathe and improve its performance.

Did you know that many people use lathe rebuilding to create unique items? They turn old lathes into creative masterpieces. Whether you want to fix an old metal lathe or learn how gear trains work, this journey can be exciting.

Let’s dive deeper into the world of lathe rebuilding and explore how to enhance your metal lathe’s gear train.

Lathe Rebuilding: Enhancing Metal Lathe Gear Train Efficiency

Lathe Rebuilding: Metal Lathe Gear Train Insights

Lathe rebuilding often involves understanding the metal lathe gear train. This gear train plays a vital role in turning machine parts accurately. Want to cut metal smoothly? A well-maintained gear train is essential! Key points include checking for worn gears and proper alignment. Did you know that small adjustments can greatly improve performance? With simple tools, you can restore your lathe to its original precision, making your projects more successful. Embrace lathe rebuilding; it might just surprise you!Understanding Metal Lathe Gear Trains

Definition and importance of gear trains in metal lathes. Key components of a metal lathe gear train.When you use a metal lathe, understanding the gear train is key. A gear train helps control the speed and power of the machine. It makes cutting metal easier and more accurate. The main parts of a gear train include:

- Gears: These turn and work together to change speed.

- Shafts: They connect the gears and keep them aligned.

- Bearings: These help the gears spin smoothly.

- Drive belts: These transfer power from the motor to the gears.

Knowing these parts helps you keep your metal lathe working well.

Why are gear trains important in metal lathes?

Gear trains improve lathe performance. They allow different cutting speeds. This helps achieve better accuracy when shaping materials. By using these systems, workers can create precise parts more efficiently.

Common Issues in Lathe Gear Trains

Signs of wear and tear in gear components. Typical failures and their impact on lathe performance.Lathe gear trains can show signs of wear like funny noises or unusual vibrations, similar to an old cat trying to meow. Common issues often arise when gears begin to wear down. This can lead to frustrating problems like poor cutting quality or unexpected stops in the middle of work. Imagine your lathe throwing a tantrum! A little maintenance can help, but ignoring it may mean costly repairs down the line. Here’s a quick table to help you understand:

| Issue | Signs | Impact |

|---|---|---|

| Worn Gears | Loud noises, skipping | Poor accuracy, decreased lifespan |

| Misalignment | Shaking lathe | Inconsistent cuts |

| Lack of Lubrication | Heat build-up | Fast gear damage |

Identifying these issues early can keep your lathe running smoothly and save you the headache of bigger problems later!

Step-by-Step Lathe Rebuilding Process

Initial assessment and disassembly. Cleaning and inspecting each component.Start by examining your lathe carefully. Look for any damage or wear. This step helps you know what needs fixing. Then, take apart all parts gently. Keep track of each piece. Cleaning comes next. Use soapy water to wash everything. A toothbrush is great for tiny areas. After cleaning, inspect each part closely. Check for cracks or rust. This way, you ensure everything works smoothly when reassembled.

What is involved in the lathe rebuilding process?

The lathe rebuilding process includes initial assessment, disassembly, cleaning, and inspecting every component.

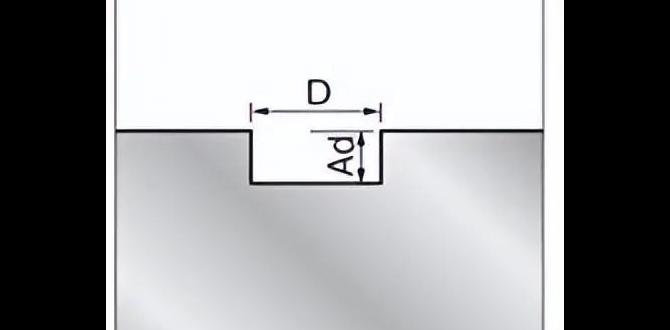

Gear Train Replacement Options

Choosing the right gears for your lathe model. Evaluating material options for durability.Selecting the right gears for your lathe model is important. Different lathes use various gear sizes and shapes. To find the best fit:

- Check your lathe manual for specifications.

- Choose gears that match in size and teeth count.

- Consider gears made from strong materials like steel or brass for lasting durability.

These materials can resist wear and tear. Picking the right gear train helps keep your lathe running smoothly and efficiently.

What should I consider when replacing lathe gears?

Consider the size, shape, and material of the gears to ensure they fit your lathe model correctly.Upgrading Your Gear Train for Better Performance

Benefits of modern gear technology. Installation tips for improved efficiency.Modern gear technology can make your lathe work better and faster. Upgrading your gear train offers many advantages. New gears provide less wear and tear, meaning your machines last longer. Also, they improve energy use, helping you save on costs. Here are some tips for great installation:

- Follow the manual for proper fit.

- Use the right tools to avoid damage.

- Test the gears after installation to ensure smooth operation.

Making these upgrades can be a game changer for your lathe. Happy rebuilding!

What are the benefits of modern gear technology?

Modern gear technology leads to more efficiency, longer lifespan, and lower operating costs.

Why upgrade your gear train?

- Better performance

- Higher accuracy

- Less noise

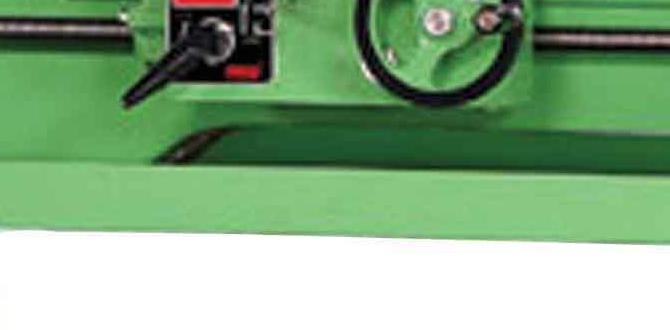

Maintenance Best Practices for Lathe Gear Trains

Regular inspection schedules. Lubrication and its role in prolonging gear life.Keeping lathe gear trains in great shape is essential. Regular inspections help catch problems early. Check for wear, vibration, and unusual noise. You should also lubricate gear trains often. This step is vital. Lubrication reduces friction and heat. It makes parts last longer. Follow this simple routine:

- Inspect every month

- Lubricate weekly or as needed

- Replace worn gears promptly

Taking these steps will keep gear trains running smoothly!

Why is lubrication important for gear trains?

Lubrication keeps gears running quietly and smoothly. It protects them from wear. Proper lubrication can boost gear life significantly.

Tools and Supplies Required for Lathe Rebuilding

Essential tools for disassembly and assembly. Recommended supplies for maintenance.Building a lathe can feel a bit like putting together a giant puzzle, except some pieces are really heavy! To disassemble and assemble your metal lathe, you’ll need essential tools like wrenches, pliers, and screwdrivers. Don’t forget protective gloves! For maintenance, stock up on lubricants and cleaning supplies. A well-oiled lathe runs smoother than a greased pig at a county fair! Here’s a handy table of must-haves:

| Tools | Supplies |

|---|---|

| Wrenches | Lubricant |

| Pliers | Cleaning solution |

| Screwdrivers | Cloth rags |

| Safety gloves | Replacement parts |

With these tools and supplies, your lathe rebuilding adventure will be a breeze, or at least a hilarious journey through oil and metal!

Cost Considerations for Lathe Rebuilding

Budgeting for parts and labor. Costbenefit analysis of DIY rebuilding vs. professional services.Rebuilding a lathe can be costly, so you should plan your budget well. Think about how much you need for parts and whether to do the work yourself or hire someone. Here are some points to consider:

- Parts costs: Check prices for gears, bearings, and tools needed.

- Labor costs: Calculate how much you might pay if you hire professionals.

- DIY savings: You might save money if you can do the work yourself.

Compare the costs of both options. A DIY approach can save cash but requires time and skill. Hiring a pro is quicker but also pricier. Choose what fits your needs best!

How much does it cost to rebuild a lathe?

The cost of rebuilding a lathe can range from $500 to $5,000. This depends on the condition of the lathe and the parts needed.

Common costs involved:

- Parts: $200-$3,500.

- Labor: $300-$1,500.

Case Studies: Successful Lathe Rebuilding Projects

Realworld examples of lathe rebuilds and outcomes. Lessons learned from different rebuilding scenarios.Many people have successfully rebuilt their lathes. These projects can teach us a lot. For example, one shop replaced worn gears. This improved precision and speed. Another case involved cleaning and greasing old parts. This simple step extended the lathe’s life. Here are some key lessons learned:

- Regular maintenance is crucial.

- Replace old parts to boost performance.

- Document each step for future reference.

By examining real examples, we see the value of timely rebuilding. These actions can transform an old lathe into a powerful tool.

What are some real-world examples of lathe rebuilds?

One example is a fabrication shop that revamped an old lathe, increasing its lifespan by 15 years. Another shop reported improved accuracy after replacing gears in their metal lathe.

Conclusion

In summary, rebuilding a metal lathe gear train can improve your machine’s performance. We learned that checking for wear and replacing parts is essential. You can enhance precision and efficiency with some effort. So, gather your tools and consider taking on a rebuild project. To deepen your understanding, explore guides and videos on lathe maintenance and gear train setups. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Rebuilding The Gear Train Of A Metal Lathe:Sure! Here are five questions about rebuilding the gear train of a metal lathe: 1. **Why do we need to rebuild the gear train?** We rebuild the gear train to make sure the lathe works well. Sometimes, parts get worn out or damaged. 2. **What tools do we need to rebuild it?** You need simple tools like a wrench, screwdriver, and sometimes a hammer. These help you take things apart and put them back together. 3. **How do we start rebuilding the gear train?** First, we turn off the lathe and unplug it. This keeps us safe. Then, we carefully take off the old gears. 4. **What should we check for when rebuilding?** We should look for broken parts, dirt, or anything that doesn’t fit well. Making sure everything is clean helps it work better. 5. **How do we know if we did it right?** We test the lathe after we rebuild it. If it runs smoothly and makes no strange noises, we did it right!

Sure! Just let me know what question you’d like me to answer.

What Are The Common Signs That Indicate The Gear Train Of A Metal Lathe Needs Rebuilding Or Maintenance?You might notice some signs that mean the gear train of a metal lathe needs fixing. Listen for strange noises like grinding or clunking sounds. If the lathe runs unevenly or gets stuck, that’s a warning too. Check for any weak or worn-out parts. If you see oil leaks or feel rough movement, it’s time to get it checked!

What Tools And Materials Are Necessary For Rebuilding The Gear Train Of A Metal Lathe?To rebuild the gear train of a metal lathe, you will need some tools and materials. First, have a set of wrenches and screwdrivers to take things apart. You will also need replacement gears and oil for smooth movement. A cleaning cloth helps keep everything tidy. Lastly, a manual for the lathe can guide you through the process.

How Can One Diagnose Gear Wear Or Misalignment Issues Within A Metal Lathe’S Gear Train?To find out if the gears on a metal lathe are worn or not lined up right, you can look for a few signs. First, listen for strange noises when the lathe is running. If you hear grinding or clunking sounds, the gears might be rough or misaligned. Next, check the gears for any visible damage or uneven wear. You can also watch the parts while they move to see if they are not lining up correctly.

What Is The Process For Disassembling And Reassembling The Gear Train In A Metal Lathe During A Rebuild?To take apart the gear train in a metal lathe, you first turn off the machine and unplug it for safety. Next, you carefully remove any covers or guards. Then, you note how the gears are connected and take them off one by one. When you’re ready to put it back together, you reverse the steps and follow your notes to make sure everything fits correctly. Finally, you test the lathe to ensure it works well.

What Are The Benefits Of Upgrading The Gear Train Components Vs. Just Repairing The Existing Ones In A Metal Lathe?Upgrading the gear train parts of a metal lathe can make it work better and last longer. New parts can help you make smoother cuts and have fewer problems. Repairing old parts might keep the machine running, but upgrades can improve its overall power. Plus, new parts can be more reliable, so you spend less time fixing things. It’s like getting a shiny new bike instead of just fixing the old one.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Rebuilding The Gear Train Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about rebuilding the gear train of a metal lathe: 1. **Why do we need to rebuild the gear train?** We rebuild the gear train to make sure the lathe works well. Sometimes, parts get worn out or damaged. 2. **What tools do we need to rebuild it?** You need simple tools like a wrench, screwdriver, and sometimes a hammer. These help you take things apart and put them back together. 3. **How do we start rebuilding the gear train?** First, we turn off the lathe and unplug it. This keeps us safe. Then, we carefully take off the old gears. 4. **What should we check for when rebuilding?** We should look for broken parts, dirt, or anything that doesn’t fit well. Making sure everything is clean helps it work better. 5. **How do we know if we did it right?** We test the lathe after we rebuild it. If it runs smoothly and makes no strange noises, we did it right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Gear Train Of A Metal Lathe Needs Rebuilding Or Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice some signs that mean the gear train of a metal lathe needs fixing. Listen for strange noises like grinding or clunking sounds. If the lathe runs unevenly or gets stuck, that’s a warning too. Check for any weak or worn-out parts. If you see oil leaks or feel rough movement, it’s time to get it checked!”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Necessary For Rebuilding The Gear Train Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild the gear train of a metal lathe, you will need some tools and materials. First, have a set of wrenches and screwdrivers to take things apart. You will also need replacement gears and oil for smooth movement. A cleaning cloth helps keep everything tidy. Lastly, a manual for the lathe can guide you through the process.”}},{“@type”: “Question”,”name”: “How Can One Diagnose Gear Wear Or Misalignment Issues Within A Metal Lathe’S Gear Train?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find out if the gears on a metal lathe are worn or not lined up right, you can look for a few signs. First, listen for strange noises when the lathe is running. If you hear grinding or clunking sounds, the gears might be rough or misaligned. Next, check the gears for any visible damage or uneven wear. You can also watch the parts while they move to see if they are not lining up correctly.”}},{“@type”: “Question”,”name”: “What Is The Process For Disassembling And Reassembling The Gear Train In A Metal Lathe During A Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take apart the gear train in a metal lathe, you first turn off the machine and unplug it for safety. Next, you carefully remove any covers or guards. Then, you note how the gears are connected and take them off one by one. When you’re ready to put it back together, you reverse the steps and follow your notes to make sure everything fits correctly. Finally, you test the lathe to ensure it works well.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Upgrading The Gear Train Components Vs. Just Repairing The Existing Ones In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Upgrading the gear train parts of a metal lathe can make it work better and last longer. New parts can help you make smoother cuts and have fewer problems. Repairing old parts might keep the machine running, but upgrades can improve its overall power. Plus, new parts can be more reliable, so you spend less time fixing things. It’s like getting a shiny new bike instead of just fixing the old one.”}}]}