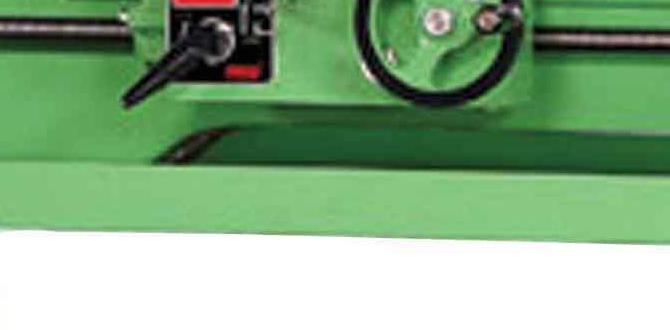

Have you ever wondered how machines create perfect parts? Lathe rebuilding is a fascinating process, especially when it comes to metal lathes. One important feature of these machines is the threading dial. This small tool can make huge differences in how well the lathe works. Imagine trying to cut threads without it! It would be much harder and less accurate.

Imagine you are in a workshop. You see a metal lathe with a threading dial. It looks simple, but it holds the key to precise work. The threading dial helps the user align the tool correctly for cutting threads. Many metalworkers rely on this tool every day. It makes their jobs easier and more fun!

In this article, we will explore how lathe rebuilding can enhance your metal lathe’s performance. We will look closely at the threading dial and why it is so essential. Get ready to learn some tips and tricks that can make your lathe work like new!

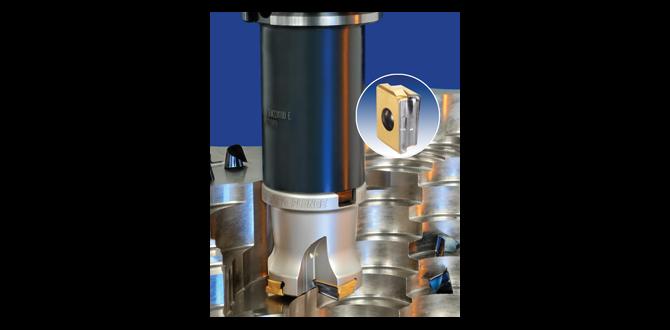

Lathe Rebuilding: Upgrading Your Metal Lathe Threading Dial — **Article:** Lathe Rebuilding Is A Crucial Process For Enthusiasts And Professionals Who Want To Enhance The Performance And Precision Of Their Metal Lathes, Especially When It Comes To The Threading Dial. In This Article, We Will Explore The Importance Of Lathe Rebuilding, The Benefits Of Having A High-Quality Threading Dial, And Some Practical Tips To Guide You Through The Rebuilding Process. Understanding Lathe Rebuilding Lathe Rebuilding Involves A Comprehensive Overhaul Of The Lathe Machine To Restore Its Functionality, Accuracy, And Efficiency. This Process May Include Repairing Or Replacing Worn-Out Components, Realigning Parts, And Upgrading Various Systems, Including The Threading Dial. The Role Of The Threading Dial The Threading Dial Is An Essential Component For Any Metal Lathe Used In Threading Operations. It Provides Indicators For Users To Align The Tool With The Workpiece, Ensuring Precision In Creating Threads. A Well-Functioning Threading Dial Allows For Meticulous Adjustments, Which Contribute To Producing Better-Quality Threads. Benefits Of Upgrading Your Threading Dial 1. **Increased Accuracy**: An Upgraded Threading Dial Allows For Precise Adjustments, Essential For Creating Accurate Threads. 2. **Improved Productivity**: A Reliable Threading Dial Can Reduce Setup Times And Enhance Overall Machining Efficiency. 3. **Enhanced Longevity**: Newer Models Of Threading Dials Are Often More Durable, Reducing The Need For Frequent Repairs. Tips For Lathe Rebuilding – **Assessment**: Start By Thoroughly Assessing Your Lathe’S Current Condition To Identify Any Areas Requiring Attention. – **Parts Replacement**: Consider Investing In High-Quality Replacement Parts For Optimal Performance, Especially When It Comes To Critical Components Like The Threading Dial. – **Consult Experts**: For Those Who Are Unsure About The Rebuilding Process, Consulting With Experienced Lathe Technicians Can Provide Valuable Insights And Assistance. Conclusion Lathe Rebuilding Is An Effective Way To Revive The Functionality Of Your Metal Lathe, Particularly Enhancing The Threading Dial. By Focusing On Upgrades And Repairs, You Can Significantly Improve Your Machining Operations, Leading To Better-Quality Output And Increased Productivity. Whether You’Re A Hobbyist Or A Seasoned Machinist, Investing Effort In Rebuilding Your Lathe Will Pay Off In The Long Run.

Lathe Rebuilding: Metal Lathe Threading Dial

Rebuilding a metal lathe, especially focusing on the threading dial, offers exciting challenges. Did you know that a precise threading dial helps create perfect threads? It allows you to align the cutting tool accurately, making your projects smoother. Understanding its mechanics can improve your skills immensely. Regular maintenance of the threading dial can extend your lathe’s lifespan. Dive into this fascinating world and discover how a small piece can make a big difference!Understanding the Basics of Lathe Rebuilding

Definition of lathe rebuilding. Importance in metalworking industry.Lathe rebuilding means fixing and updating a lathe machine. Think of it like giving your car a tune-up, but for metalwork! This process is essential in the metalworking industry, helping machines work better and last longer. A well-maintained lathe can save time and money. Plus, it keeps your projects running smoothly. Without rebuilding, lathe machines might act up like a stubborn cat refusing a bath!

| Benefits of Lathe Rebuilding |

|---|

| Improved Accuracy |

| Increased Lifespan |

| Cost-Effective |

| Better Performance |

Signs Your Metal Lathe Needs Rebuilding

Common issues and symptoms. Impact on performance and precision.Is your metal lathe starting to act like a stubborn mule? Look for signs that it might need some TLC! Common issues include strange noises or a choppy threading dial. These quirks can mess with how well you create parts. If your lathe can’t hold its precision, it’s like trying to thread a needle while blindfolded—pretty tricky! Here’s a quick table of key symptoms:

| Signs | Impact |

|---|---|

| Unusual sounds | Decreased accuracy |

| Difficulty in threading | Poor surface finish |

| Inconsistent speeds | Time wasted and frustration |

Recognizing these problems early on can save you from bigger headaches later. Like your favorite pair of shoes, a little maintenance goes a long way!

Tools Required for Lathe Rebuilding

Essential tools and equipment needed. Safety measures to consider.Rebuilding a lathe requires some special tools. Think of it as gathering your superhero gear! You’ll need wrenches, screwdrivers, and a quality dial indicator. Don’t forget safety goggles; no one wants flying metal shavings in their eyes! A well-lit workspace is also important for a clear view. Here’s a handy table to keep those essentials in check:

| Tool | Purpose |

|---|---|

| Wrenches | Tightening and loosening parts |

| Screwdrivers | Adjusting screws |

| Dial Indicator | Measuring precision |

| Safety Goggles | Protecting your eyes |

Always double-check your gear and make sure you’re prepared. Remember, safety first, then metal magic!

Step-by-Step Guide to Rebuilding a Metal Lathe

Detailed breakdown of the rebuilding process. Specific focus on the threading dial assembly.Rebuilding a metal lathe is a fun project! Start by cleaning all parts. Make sure to check for wear and tear. Next, focus on the threading dial assembly. Here are key steps:

- Remove the old dial carefully.

- Inspect the gears for damage.

- Install the new threading dial.

- Ensure it aligns correctly with the spindle.

- Test it by threading a piece of metal.

Follow these steps for a smooth rebuild!

What should I check in the threading dial assembly?

Check for any broken gears and ensure smooth movement. This will help your lathe work better.

Tuning and Adjusting the Threading Dial

Techniques for precise threading. Calibration tips for accurate results.Tuning your threading dial can improve your results. Start by checking if the dial is aligned correctly. Use the following tips for precision:

- Calibrate the dial regularly to ensure accuracy.

- Test with scrap material before working on your final project.

- Adjust settings slowly to see how each change affects your work.

These techniques will help you create precise threads every time.

How can I achieve precise threading on my lathe?

Achieving precise threading requires regular calibration and careful adjustments. Testing on scrap material helps confirm your settings before starting the actual work. This ensures accuracy and quality in your projects.

Common Mistakes to Avoid During Rebuilding

Pitfalls in the rebuilding process. Tips for troubleshooting errors.Rebuilding a lathe can be tricky. Many people make easy mistakes. Here are some common pitfalls:

- Not measuring correctly.

- Skipping cleaning steps.

- Forgetting to check parts before putting them back.

To fix errors quickly, follow these tips:

- Look for loose screws.

- Double-check all measurements.

- Refer to the manual often.

Learning from mistakes helps you improve. Stay patient and focused. Rebuilding can be fun!

What should I do if my lathe is not working after rebuilding?

First, check for loose connections. Next, ensure that all parts are properly aligned. Look at the manual for troubleshooting steps. Don’t hesitate to seek help from others if needed!

Preventive Maintenance for Longevity

Best practices to maintain lathe condition. Scheduling routine checks on the threading dial.Keeping your lathe in top shape is important for good performance. Regular checks can prevent big problems later. Schedule routine checks on the threading dial to catch issues early. Here are some tips to help you maintain your lathe:

- Clean the lathe often to remove dust and chips.

- Check oil levels and refill as needed.

- Inspect belts and gears for wear.

- Test the threading dial for smooth operation.

- Keep tools organized and ready to use.

Why is routine maintenance necessary?

Routine maintenance helps extend your lathe’s lifespan. By caring for it regularly, you can avoid costly repairs and keep everything running smoothly. Remember, a well-maintained lathe is a happy lathe!

Resources and Tools for Further Learning

Recommended books and manuals. Online forums and communities for support.Learning about lathe rebuilding can be exciting. Many resources can help you dive deeper. Books and manuals give clear instructions. Here are some great options:

- The Metal Lathe by Tom McBroom

- Lathe Work: A Home Workshop Guide by Patrick Hutchinson

Online forums and communities offer support too. They connect you with others who share your interests. You can ask questions and share your ideas. Websites like Reddit and specific lathe groups are great places to start.

What are some good resources for learning about lathes?

Check out books like The Metal Lathe and join online forums like Reddit for support and ideas.Conclusion

In summary, rebuilding a metal lathe can enhance its performance, especially the threading dial. You can improve accuracy and extend its life by maintaining your lathe well. If you’re interested in DIY projects, exploring lathe rebuilding can be rewarding. We encourage you to read more about lathe maintenance and techniques to deepen your understanding. Happy machining!FAQs

What Are The Common Signs Of Wear Or Damage In A Threading Dial On A Metal Lathe That Indicate It May Need Rebuilding?You can spot problems with a threading dial if it’s hard to turn. Look for cracks or chips on its surface. If the numbers seem blurry or hard to read, it might be worn out. A rusty or dirty dial can also mean it needs fixing. If it skips numbers while you turn it, that’s a big sign it needs help!

Sure! Please provide the question you’d like me to answer.

What Step-By-Step Process Should Be Followed For Rebuilding The Threading Dial On A Metal Lathe?First, turn off the metal lathe and unplug it for safety. Next, take off the old threading dial carefully. Then, clean the area where the dial goes. After that, put on the new threading dial and secure it tightly. Finally, plug the lathe back in and test the dial to make sure it works.

Sure! Please give me the question you’d like me to answer.

How Can Inaccuracies In Threading Be Diagnosed And Corrected During The Rebuilding Of A Lathe’S Threading Dial?To find problems with the threading dial on a lathe, you can follow a few steps. First, check if the numbers on the dial line up with the actual threads. Next, use a ruler to measure the distance between threads. If the measurements don’t match, adjust the dial until they do. Finally, test it out by making some new threads and see if they look right.

Sure! Please ask your question, and I’ll be happy to help with a short answer.

What Tools And Materials Are Typically Required For A Successful Lathe Threading Dial Rebuild?To rebuild a lathe threading dial, you need a few tools and materials. First, get a screwdriver to take everything apart. You’ll also need a wrench to loosen nuts and bolts. Make sure you have some grease to make the parts move smoothly. Lastly, have a clean cloth handy to wipe off dirt and oil.

Sure! Please tell me the question you would like me to answer.

How Does The Alignment Of The Threading Dial Affect The Overall Performance And Precision Of Threading Operations On A Metal Lathe?The threading dial helps you cut threads on metal accurately. If it’s aligned correctly, your threads will be even and smooth. An out-of-place dial can cause messy threads and mistakes. You need to check it often to keep your work looking nice. Good alignment makes your lathe work better and saves time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage In A Threading Dial On A Metal Lathe That Indicate It May Need Rebuilding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot problems with a threading dial if it’s hard to turn. Look for cracks or chips on its surface. If the numbers seem blurry or hard to read, it might be worn out. A rusty or dirty dial can also mean it needs fixing. If it skips numbers while you turn it, that’s a big sign it needs help!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Step-By-Step Process Should Be Followed For Rebuilding The Threading Dial On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, turn off the metal lathe and unplug it for safety. Next, take off the old threading dial carefully. Then, clean the area where the dial goes. After that, put on the new threading dial and secure it tightly. Finally, plug the lathe back in and test the dial to make sure it works.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “How Can Inaccuracies In Threading Be Diagnosed And Corrected During The Rebuilding Of A Lathe’S Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find problems with the threading dial on a lathe, you can follow a few steps. First, check if the numbers on the dial line up with the actual threads. Next, use a ruler to measure the distance between threads. If the measurements don’t match, adjust the dial until they do. Finally, test it out by making some new threads and see if they look right.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help with a short answer.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Typically Required For A Successful Lathe Threading Dial Rebuild?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild a lathe threading dial, you need a few tools and materials. First, get a screwdriver to take everything apart. You’ll also need a wrench to loosen nuts and bolts. Make sure you have some grease to make the parts move smoothly. Lastly, have a clean cloth handy to wipe off dirt and oil.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please tell me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Threading Dial Affect The Overall Performance And Precision Of Threading Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you cut threads on metal accurately. If it’s aligned correctly, your threads will be even and smooth. An out-of-place dial can cause messy threads and mistakes. You need to check it often to keep your work looking nice. Good alignment makes your lathe work better and saves time!”}}]}