Have you ever wondered how the machines in a workshop stay so precise? Machines, like metal lathes, need care and adjustment. A lathe repair kit can be a game-changer for anyone who uses these tools.

Imagine trying to create a perfect circle, but your lathe keeps wobbling. Frustrating, right? This is where lathe alignment comes into play. Proper alignment makes a huge difference in the quality of your work.

Fun fact: even small misalignments can lead to big problems! Over time, they can cause parts to wear out faster. A good lathe repair kit helps you fix these issues and keep your lathe running smoothly.

Ready to dive deeper into the world of lathes? Let’s explore how to keep these amazing machines in top shape with the right tools and knowledge!

Lathe Repair Kit: Essential For Metal Lathe Alignment

Understanding Lathe Repair Kits for Metal Lathe Alignment

Did you know that a well-aligned metal lathe can save you time and mistakes? A lathe repair kit is essential for keeping your machine in top shape. These kits often include tools to help you align the lathe accurately. Proper alignment ensures smooth operation and better finished products. You’ll learn to identify the signs of misalignment, and how a repair kit can be your best friend in fixing these issues. Keeping your lathe aligned means more efficiency and less rework!Common Issues with Lathe Alignment

Identifying misalignment symptoms. Consequences of poor alignment on machining quality.Misalignment in lathe machines can cause big problems. Look out for signs like uneven cuts or strange noises. These can mean the lathe is not correctly aligned. Poor alignment leads to:

- Inaccurate workpieces.

- Increased wear on tools.

- Wasted materials and time.

Fixing these issues quickly can save you money and improve your work quality.

How do you know your lathe is misaligned?

Common signs include rough finishes or vibrations when cutting. Watching for these symptoms can prevent bigger problems.

What to Look for in a Lathe Repair Kit

Essential tools and components included. Quality and compatibility considerations.Choosing the right lathe repair kit is essential. Look for basic tools like wrenches and aligners. Make sure the components are compatible with your metal lathe. Quality matters too. A well-made kit lasts longer and helps you do better work. Check for customer reviews to ensure you get a trusted product.

What tools should be included in a lathe repair kit?

The kit should have:

- Measuring Tools: For accuracy.

- Wrenches: To loosen or tighten parts.

- Aligners: To ensure proper setups.

Step-by-Step Guide to Aligning Your Metal Lathe

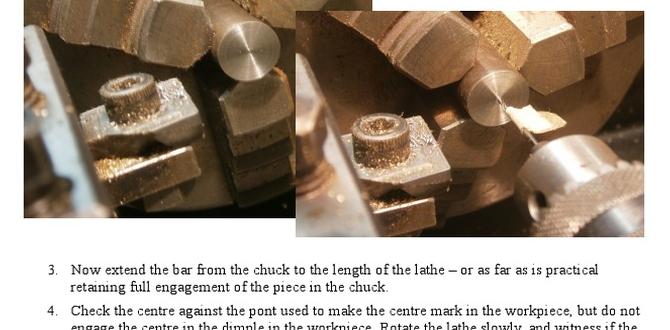

Preparatory steps before repair. Detailed alignment procedure.Before you start aligning your metal lathe, take some time for preparatory steps. First, ensure your workspace is clean and organized. Gather all the tools you need, like wrenches and a straightedge. Then, turn off the power to your lathe. Once ready, follow this detailed alignment procedure:

- Check the bed for levelness.

- Use a dial indicator to measure any misalignment.

- Adjust the tailstock and headstock if needed.

- Recheck the alignment after adjustments.

Remember to work carefully. Proper alignment helps in achieving better precision in your tasks. You’ll enjoy the benefits in your projects!

How to align a metal lathe?

Start by leveling the bed, then check for any misalignment using a dial indicator. Adjust the tailstock or headstock as necessary. Recheck everything to ensure accuracy. This will make your lathe work better and last longer!

Manufacturer Recommendations for Lathe Repair Kits

Top brands and their offerings. Comparison of features and pricing.Many trusted brands create lathe repair kits. Here are a few top ones:

- Brand A: Known for quality and affordable prices, they offer a solid all-in-one kit.

- Brand B: This brand has a slightly higher price but provides extra tools for any metal lathe.

- Brand C: The most expensive, but many say their kits last longer and work better.

When picking a kit, compare features and prices carefully. Investing in a quality kit can save you money in the long run.

What features should you look for in a lathe repair kit?

Look for durable tools, clear instructions, and compatibility with your lathe model.

Maintenance Tips to Prevent Alignment Issues

Routine checks and adjustments. Best practices for lathe care.Taking care of your lathe helps it work better and last longer. Regular checks can catch problems early. Here are some quick tips:

- Check the alignment often. Use a level for accuracy.

- Keep parts clean. Dust can cause problems.

- Adjust loose bolts to keep everything tight.

- Lubricate moving parts for smooth operation.

Following these tips can prevent big issues and save you time and money.

How often should I check my lathe alignment?

Check your lathe alignment every month or whenever you notice changes in performance. Regular checks help keep your machine in good shape.

Practice good lathe care.

Clean your workspace and keep tools in order. A tidy area leads to better work. Remember, a little care goes a long way!

DIY vs Professional Lathe Repair Services

Pros and cons of handling repairs yourself. When to seek professional assistance.Some people like to fix their lathe machines by themselves. This can save money and give them satisfaction. However, DIY repairs have risks. You might not have all the right tools or skills. Here are some pros and cons:

- Pros: Save money, gain experience, personal satisfaction.

- Cons: Risk of making problems worse, using wrong parts, possible injury.

When your lathe has complex issues, it’s better to call a professional. They have the right knowledge and tools to fix it safely. If you’re not sure about a repair, don’t hesitate to ask for help.

When should you seek professional help?

If repairs seem too hard or risky, call a pro. They can solve problems quickly and correctly. Save time and avoid stress!

Customer Reviews and Experiences with Lathe Repair Kits

Insights from users about kit effectiveness. Case studies of successful alignments.Many users say lathe repair kits work well for fixing problems. They help with metal lathe alignment, making machines run smoother. Some people shared success stories, showing how easy it was to realign their lathes. For example, one user aligned their lathe in under an hour!

- Improved accuracy in cuts.

- Less wear on machine parts.

- Simple instructions for setup.

These kits are not just tools; they are solutions that help make projects easier and more fun. User reviews highlight how effective these kits can be, leading to happier and more productive machining experiences.

What do customers say about lathe repair kits?

Customers find lathe repair kits helpful for quick and effective repairs. Many report improved performance after using them. The kits are praised for their easy-to-follow instructions and noticeable results.

Conclusion

In conclusion, a lathe repair kit helps keep your metal lathe in top shape. Proper alignment is key for smooth operation and accurate cuts. Always check your lathe’s alignment regularly. If you’re unsure, consult a guide or ask an expert. We encourage you to explore more about lathe maintenance to improve your skills. Happy machining!FAQs

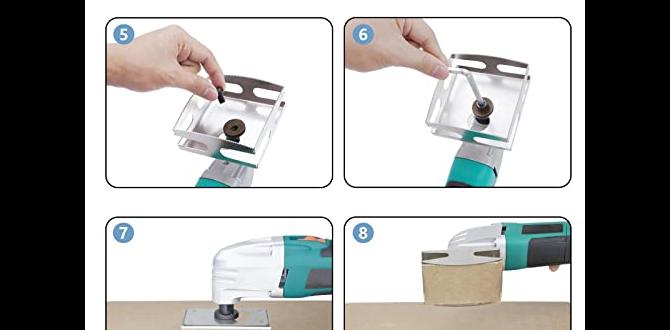

What Components Are Typically Included In A Lathe Repair Kit For Ensuring Proper Alignment Of A Metal Lathe?A lathe repair kit usually has a few important tools. You’ll find a level to check if the lathe is straight. There are also alignment bars to help you adjust parts. Sometimes, you get shims, which are small pieces that fill gaps. These tools help keep everything working well together.

How Can I Determine If My Metal Lathe Is Misaligned, And What Signs Should I Look For?To check if your metal lathe is misaligned, watch for signs like uneven cuts or surprising vibrations. You can try turning a simple shape, like a cylinder. If it’s not smooth or has bumps, the lathe might be off. Also, make sure the tools fit snugly in place and don’t wobble. If you notice any of these problems, it’s time to adjust your lathe.

What Are The Step-By-Step Procedures For Aligning A Metal Lathe Using A Repair Kit?To align a metal lathe with a repair kit, follow these steps. First, make sure the lathe is turned off. Next, check that the base is level using a bubble level. Then, adjust the feet of the lathe until it is level. After that, use the repair kit to tighten any loose screws or parts. Finally, test the lathe by running it and watching for wobbling.

How Often Should A Metal Lathe Be Checked For Alignment, And What Factors Can Affect Its Accuracy Over Time?You should check a metal lathe for alignment at least every few months. Regular use can wear it down. Dust, heat, and moisture can also change how it works. If you move the lathe, check it right away. Keeping it aligned helps your work be more accurate.

What Tools And Techniques Are Recommended For Performing Precision Alignment On A Metal Lathe During Repairs?To align a metal lathe, you can use dial indicators. These help you measure distance very accurately. A level is also useful to check if the lathe is straight. You might use a straightedge, which is a flat tool, to see if everything lines up. It’s important to take your time and check your work!