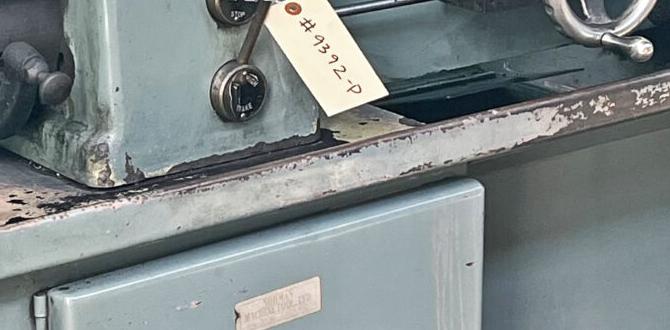

Have you ever seen a metal lathe in action? It’s a machine that spins metal to shape it into different parts. Many people use these lathes in workshops and factories. But what happens when they break down? That’s where a lathe repair kit comes to the rescue!

Imagine working on a project when suddenly, your metal lathe stops working. It’s frustrating, right? Instead of panicking, you can grab your lathe repair kit. This handy kit can help you fix many common problems quickly.

Now, let’s talk about automation. Have you noticed how machines are becoming smarter? With the right upgrades, you can turn your metal lathe into an automated tool. This means you’ll spend less time fixing it and more time creating. Sounds exciting, doesn’t it?

In this article, we will explore how lathe repair kits work. We’ll also dive into the fascinating world of metal lathe automation. Get ready to learn how to keep your machines running smoothly!

Comprehensive Guide To Lathe Repair Kit For Metal Lathe Automation

Lathe Repair Kit: Enhancing Metal Lathe Automation

Lathe repair kits are essential for anyone using metal lathes. These kits help keep machines in top shape for precise work. Have you ever thought about how automation can reduce errors and save time? With a repair kit, you can fix small issues before they turn into big problems. Whether you’re a beginner or a seasoned pro, understanding lathe maintenance can improve your skills. A well-maintained lathe leads to better projects and smoother operations. Don’t underestimate the importance of these handy kits!What is a Lathe Repair Kit?

Definition and purpose of a lathe repair kit. Components typically included in a lathe repair kit.A lathe repair kit helps fix problems with lathes. Lathes shape metal, wood, or plastic. When they break, this kit saves the day. It typically includes:

- Replacement belts

- Bearings

- Seals

- Gaskets

- Tools for easy installation

Having a repair kit ready means you can get back to work quickly. It’s an essential part of keeping your lathe running well.

What is usually found in a lathe repair kit?

Common items include bearings, belts, gaskets, and tools. These parts help keep the lathe working smoothly.

Benefits of Using a Lathe Repair Kit

Costeffectiveness compared to hiring professionals. Improved efficiency and automation in lathe operations.Using a lathe repair kit is like having a superhero tool in your workshop! First, it’s way cheaper than hiring a pro. You save money while fixing things yourself. Who doesn’t love extra cash for snacks? Second, these kits help speed up your work. With improved efficiency and some snazzy automation, you can get things done faster than ever before. More time for fun, less time waiting!

| Benefit | Details |

|---|---|

| Cost-Effectiveness | Doing it yourself saves cash! |

| Increased Efficiency | Get your work done faster! |

Key Features to Look for in a Lathe Repair Kit

Quality of materials and components. Compatibility with automated systems.When choosing a lathe repair kit, check the quality of materials. A strong kit uses durable parts that won’t break easily. Think of it as picking a superhero’s gear. You want the best! Also, consider compatibility with automated systems. Not all kits play nice together. A good fitting ensures smooth operation, making everything run like a well-oiled machine—literally! Here are the key features:

| Feature | Description |

|---|---|

| Material Quality | Strong and durable components that last a long time. |

| Compatibility | Must work with your automated systems to avoid awkward dances. |

Step-by-Step Guide to Using a Lathe Repair Kit

Important safety precautions before starting repairs. Detailed instructions for common repairs using the kit.Before you dive into repairs, remember to put on your safety glasses. No one wants metal shavings in their eyes! Also, keep your workspace clean. A tidy area is a happy area. For common repairs using your lathe repair kit, follow these steps:

| Repair Type | Steps |

|---|---|

| Headstock Adjustment | Loosen screws, align the headstock, and tighten screws. Easy as pie! |

| Bed Leveling | Use a level to check alignment and adjust feet as needed. Make it snug! |

| Tailstock Repair | Check for looseness. Tighten or replace screws. No wobbly tailstocks allowed! |

Following these tips can help keep your lathe running smoothly. Remember, measure twice, cut once, and avoid acting like a mad scientist in the process!

Common Issues Addressed by Lathe Repair Kits

Identification of frequent problems encountered in metal lathes. How repair kits effectively solve these problems.Metal lathes can face various issues. Common problems include:

- Worn bearings

- Damaged gears

- Misalignment

- Tool wear

Repair kits are a great solution. They contain parts needed for fixes. These kits can help restore smooth operation. With a repair kit, users can fix their machines quickly. This keeps projects on track and saves time.

What can repair kits fix on metal lathes?

Repair kits can fix worn parts, alignment issues, and tool wear. They help to keep the lathe running well and ensure high-quality work.

Tips for Maintaining Your Metal Lathe for Longevity

Regular maintenance practices to prevent breakdowns. Importance of using quality repair kits for longevity.To keep your metal lathe running smoothly, regular care is key. Check for wear and tear often. Clean it after each use to avoid debris buildup. Lubricate moving parts with quality oil. Doing these things can help prevent breakdowns, saving time and money. Also, using a good repair kit is important. Quality parts last longer and keep your lathe in top shape. Investing a little now can save big later!

What are some regular maintenance tips for a metal lathe?

Check and clean your lathe regularly, lubricate moving parts, and use quality repair kits.

Simple Maintenance Tips:

- Inspect belts and gears for wear.

- Keep the workspace tidy.

- Replace worn-out parts quickly.

Customer Reviews: Best Lathe Repair Kits in the Market

Summary of toprated lathe repair kits based on customer feedback. Analysis of customer experiences with metal lathe automation repairs.Finding the best lathe repair kits is easier with customer reviews! Many users praised their kits for being full of helpful parts and easy to use, like a toolbox for superheroes. Customers shared stories of how these kits turned their broken metal lathes into smooth-operating machines again.

| Repair Kit | Customer Rating | Common Feedback |

|---|---|---|

| Super Lathe Fix | 4.8/5 | Very effective and user-friendly! |

| Easy Peasy Lathe Kit | 4.5/5 | Perfect for DIY enthusiasts! |

| Quick Repair Set | 4.7/5 | Great value for the price! |

Overall, customers love how these kits make lathe automation repairs feel like a walk in the park—or at least a smooth ride! With glowing reviews, these repair kits save the day, proving that even machines need a little love now and then.

Frequently Asked Questions About Lathe Repair Kits

Common inquiries regarding selection and use of lathe repair kits. Troubleshooting tips for users facing issues with their kits.Many people have questions about lathe repair kits. Choosing the right kit can be tough. Here are some common inquiries:

What should I look for in a lathe repair kit?

Consider the list of parts included, compatibility with your lathe, and ease of installation.

How do I troubleshoot my kit?

If your kit is not working well, check these:

- Inspect all components for damage.

- Ensure proper installation.

- Look for software updates if it’s automated.

Understanding these points can help you make the best choice and fix any issues quickly.

Conclusion

In conclusion, a lathe repair kit is essential for maintaining your metal lathe. Automation can enhance its efficiency and precision. By using these tools, you can improve your projects and save time. We encourage you to explore more about lathe maintenance and automation. Happy crafting!FAQs

What Are The Essential Components Included In A Lathe Repair Kit For Metal Lathes?A lathe repair kit for metal lathes includes important tools. You will find wrenches, screwdrivers, and pliers. There are also spare belts and gears to replace broken ones. Don’t forget lubrication oil to keep everything running smoothly. Finally, a cleaning brush helps keep the lathe clean and working well.

How Can Automation Be Integrated Into A Metal Lathe To Enhance Precision And Efficiency?We can add machines that control the metal lathe automatically. These machines help it to cut metal pieces quicker and more accurately. You can set the right measurements, and the lathe does the work without mistakes. This saves time and makes sure everything is perfect. Using sensors can help check if the parts are right as they are made.

What Are Common Issues That Metal Lathes Face That Can Be Addressed With A Repair Kit?Metal lathes can have problems like worn parts, broken belts, or loose screws. A repair kit usually has tools and pieces to fix these issues. You can change a dull tool or replace a broken belt with it. This helps the lathe work better and last longer. Regular checks and quick fixes mean you can keep making cool things!

How Does The Use Of Automated Systems Impact The Maintenance Requirements For Metal Lathes?Using automated systems on metal lathes can make maintenance easier for you. These systems often have fewer moving parts, which means there’s less to break. You may not need to check them as often as older machines. However, you still need to keep an eye on things to make sure everything runs smoothly. Regular cleaning and checking help the machines last longer.

What Safety Considerations Should Be Taken Into Account When Repairing Or Automating A Metal Lathe?When repairing or automating a metal lathe, we need to be very careful. Always wear safety glasses to protect your eyes. Keep your hands away from moving parts to avoid injuries. Make sure the lathe is turned off before you start working on it. Lastly, be aware of any sharp tools or edges while you are near the machine.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Included In A Lathe Repair Kit For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes includes important tools. You will find wrenches, screwdrivers, and pliers. There are also spare belts and gears to replace broken ones. Don’t forget lubrication oil to keep everything running smoothly. Finally, a cleaning brush helps keep the lathe clean and working well.”}},{“@type”: “Question”,”name”: “How Can Automation Be Integrated Into A Metal Lathe To Enhance Precision And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can add machines that control the metal lathe automatically. These machines help it to cut metal pieces quicker and more accurately. You can set the right measurements, and the lathe does the work without mistakes. This saves time and makes sure everything is perfect. Using sensors can help check if the parts are right as they are made.”}},{“@type”: “Question”,”name”: “What Are Common Issues That Metal Lathes Face That Can Be Addressed With A Repair Kit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes can have problems like worn parts, broken belts, or loose screws. A repair kit usually has tools and pieces to fix these issues. You can change a dull tool or replace a broken belt with it. This helps the lathe work better and last longer. Regular checks and quick fixes mean you can keep making cool things!”}},{“@type”: “Question”,”name”: “How Does The Use Of Automated Systems Impact The Maintenance Requirements For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using automated systems on metal lathes can make maintenance easier for you. These systems often have fewer moving parts, which means there’s less to break. You may not need to check them as often as older machines. However, you still need to keep an eye on things to make sure everything runs smoothly. Regular cleaning and checking help the machines last longer.”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Taken Into Account When Repairing Or Automating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When repairing or automating a metal lathe, we need to be very careful. Always wear safety glasses to protect your eyes. Keep your hands away from moving parts to avoid injuries. Make sure the lathe is turned off before you start working on it. Lastly, be aware of any sharp tools or edges while you are near the machine.”}}]}