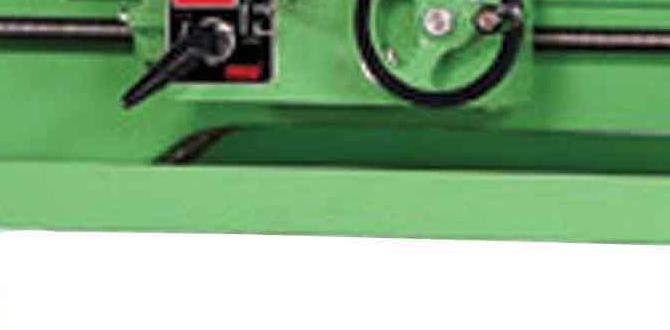

Have you ever wondered how a metal lathe works? These machines help shape metal into amazing designs. But what happens when something goes wrong?

Every metal lathe needs a good repair kit to keep it running smoothly. One important part of this kit is the lathe belt. Without a proper belt, your machine might not work at all.

Imagine you are in the middle of an exciting project. Suddenly, your lathe stops! What if I told you that a simple lathe repair kit could save the day? That’s right! With the right tools, you can get your lathe back to work.

In this article, we will explore why a lathe repair kit, especially one with a quality metal lathe belt, is essential for hobbyists and professionals alike. Are you ready to dive into the world of lathe repair?

Essential Lathe Repair Kit For Metal Lathe Belt Maintenance

Lathe Repair Kit: Metal Lathe Belt

A lathe repair kit can save you time and money when fixing your metal lathe. Did you know a worn belt can slow down your projects? With a new belt, your machine runs smoothly again. This kit often includes tools and instructions for easy installation. Imagine the satisfaction of completing your lathe repairs on your own! Whether you’re a hobbyist or a professional, upgrading your lathe with a repair kit can enhance your work.Understanding Lathe Repair Kits

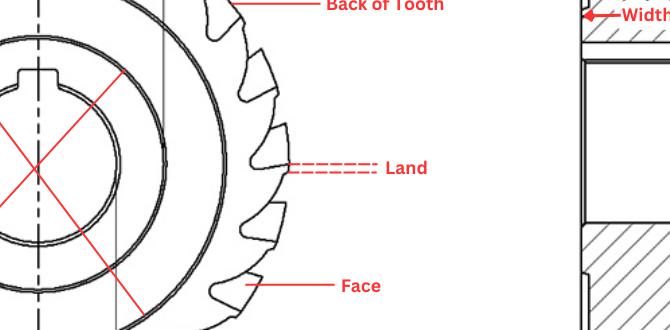

Definition and components of a lathe repair kit. Importance for maintaining metal lathes.A lathe repair kit helps fix and maintain metal lathes. It usually contains important parts like belts, pulleys, and bearings. These pieces work together to keep the lathe running smoothly. Regularly using a lathe repair kit is key for lasting performance and safety. A good kit prevents unexpected breakdowns and helps avoid costly repairs. Proper maintenance saves time and effort.

What’s in a lathe repair kit?

- Belts: Help the machine move parts smoothly.

- Pulleys: Assist in transferring motion effectively.

- Bearings: Ensure parts turn without friction.

Why is it important?

Using a lathe repair kit keeps your machine working well. It helps you avoid serious problems and keeps tools safe. Did you know a well-maintained lathe can last twice as long? Using repair kits is smart for metal lathe owners.

Common Problems Addressed by Lathe Repair Kits

Typical wear and tear issues in metal lathe belts. Troubleshooting and identification of common belt problems.Metal lathe belts can face typical wear and tear from heavy use. Common issues include fraying, cracking, and slipping, which can slow down your work or even cause accidents. Identifying these problems early is key. Look for signs like odd noises or vibrations. Ignoring these can turn a minor hiccup into a major headache! Check the belt tension regularly to avoid slipping. Here’s a handy table to spot key problems:

| Problem | Signs | Solution |

|---|---|---|

| Fraying | Visible wear | Replace immediately |

| Cracking | Surface cracks | Check alignment |

| Slipping | Low tension | Tighten the belt |

How to Choose the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Compatibility with different metal lathe models.Choosing the right repair kit is important for smooth lathe operation. First, check compatibility. Does it match your metal lathe model? It’s essential! Next, consider the parts it includes. Look for durable materials that will last. A good kit should have all necessary belts and tools. Check reviews and ask experts for advice. Are you looking for quality? Always pick kits from trusted brands to avoid problems.

Why is compatibility important?

Compatibility ensures the kit fits your lathe perfectly. This helps avoid issues during repairs and keeps your machine running smoothly.

Factors to consider:

- Brand and model of your lathe.

- Parts included in the kit.

- Material quality of the belts.

Step-by-Step Guide to Using a Lathe Repair Kit

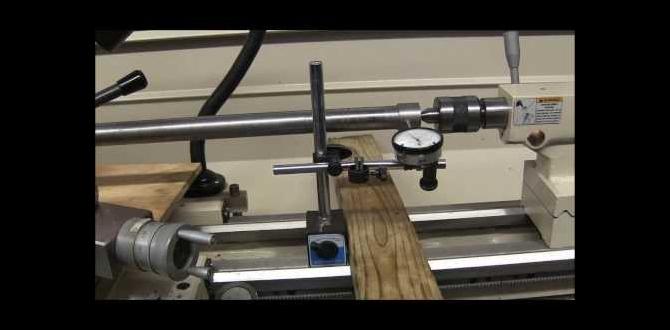

Detailed instructions for repairing metal lathe belts. Essential tools and safety precautions.To fix a metal lathe belt, gather your tools. You will need a wrench, screwdriver, and replacement belt. First, turn off the lathe and unplug it for safety. Check the old belt for damage. If it’s broken, remove it carefully. Install the new belt by looping it over the pulleys. Adjust the tension so it fits snugly. Finally, plug the device back in and test it. Always wear safety glasses when working!

What tools do I need for a lathe repair kit?

You need a wrench, screwdriver, replacement belt, and safety glasses. These tools help you safely replace the belt on your lathe.

Essential safety precautions:

- Always unplug the lathe before starting work.

- Wear gloves and safety glasses.

- Work in a clean, dry area.

Maintenance Tips for Extending Lathe Belt Lifespan

Best practices for routine maintenance of belts. Signs that indicate it’s time for a replacement.Keeping your lathe belt happy is key to a long life! Regularly check it for wear and tear. Oil the pulleys every now and then, too. Watch for signs like cracks or fraying—these mean it’s time to get a new one. If it starts slipping off, it’s waving a red flag! Remember, a healthy lathe belt equals smooth production. Below are some tips to keep your belt in check:

| Tip | Action |

|---|---|

| Check for wear | Look for cracks or frayed edges |

| Oil the pulleys | Use suitable lubricant regularly |

| Watch for slipping | Replace if it won’t stay on |

So, treat that belt like royalty, and it will serve you well!

Where to Buy Quality Lathe Repair Kits

Recommendations for trusted suppliers and brands. Factors that affect pricing and availability.Finding a reliable place to buy lathe repair kits can feel like searching for a needle in a haystack. Fortunately, a few trusted suppliers always stand out. Check out brands like Grizzly and Jet for quality kits that keep your tools running smoothly. Keep an eye on prices, as they can change based on availability and demand. Remember, a great deal today might cost you more tomorrow!

| Supplier | Specialty |

|---|---|

| Grizzly | High-quality machinery |

| Jet | Reliable repair parts |

| Amazon | Wide selection |

Don’t forget to compare prices online! You might find gems at different stores. Plus, local hardware stores often carry what you need. Happy repairing, and may your lathe run like a dream!

Frequently Asked Questions About Lathe Repair Kits

Common queries and solutions regarding lathe repairs. Expert insights and tips for troubleshooting issues.Many people wonder about common lathe repair questions. It’s like trying to understand why cats love boxes! First, you might ask, “What can break on a lathe?” Well, parts like belts wear out. That’s where a lathe repair kit comes in handy. People often ask about the best way to troubleshoot. Keep it simple! Check for loose screws and worn belts first. If you need replacements, make sure they fit your machine. Always read the manual and remember: if it doesn’t squeak, it’s happy!

| Common Question | Simple Answer |

|---|---|

| What’s the main cause of lathe issues? | Worn belts and loose parts! |

| How do I know if I need a repair kit? | If your lathe starts making weird noises! |

Conclusion

In summary, a lathe repair kit for a metal lathe belt is essential for smooth operation. Regular maintenance keeps your lathe working efficiently. You can find various kits that fit your needs. We suggest checking reviews to choose the best one. Don’t hesitate to dive deeper into lathe maintenance for better skills and knowledge.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits For Metal Lathe Belts:Sure! Here are five related questions on lathe repair kits for metal lathe belts: 1. What is a lathe repair kit? A lathe repair kit has tools and parts to fix a lathe. It helps you repair worn-out or broken belts. 2. Why do lathe belts need repairs? Lathe belts can wear out or break when used a lot. We need to fix or replace them to keep the lathe working well. 3. How do I know if my lathe belt needs repair? You can check the belt for cracks or tears. If it slips often, it might need repair too. 4. Can I fix the lathe belt myself? Yes, you can fix the lathe belt yourself! Use the repair kit and follow the instructions carefully. 5. Where can I buy a lathe repair kit? You can find lathe repair kits at hardware stores or online. Look for one that matches your lathe model.

Of course! Please provide me with the specific question you’d like me to answer, and I’ll be happy to help.

What Are The Common Signs That A Metal Lathe Belt Needs To Be Replaced Or Repaired?You might notice a metal lathe belt needs fixing if it looks frayed or cracked. If it makes strange noises while running, it’s a sign too. Sometimes, the belt may slip or stop moving the machine correctly. If you see any of these signs, it’s time to check the belt.

How Do I Choose The Right Repair Kit For My Specific Model Of Metal Lathe?To choose the right repair kit for your metal lathe, first, check your lathe’s brand and model. Look for the repair kits made specifically for that brand and model. You can ask the store staff for help if you’re not sure. Read reviews or ask friends who have the same lathe. This way, you’ll find the best kit for your machine!

What Tools Are Typically Required To Install A New Lathe Belt From A Repair Kit?To install a new lathe belt, you usually need a few tools. First, grab a wrench to loosen the bolts. You also need a screwdriver to take off the cover. A pair of pliers can help pull and push the belt into place. Finally, make sure you have a clean cloth to wipe your hands and the lathe.

Are There Different Types Of Belts Available For Metal Lathes, And How Do I Determine Which Is Best For My Machine?Yes, there are different types of belts for metal lathes, like flat belts and V-belts. To choose the best one, you need to check your machine’s manual. It will tell you the size and type of belt you need. You can also ask a shop expert for help. Make sure the belt fits right so your machine works well!

What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Belt?To help your metal lathe belt last longer, you should keep it clean. Dust and dirt can wear it down. Check it for cracks or damage often, and replace it when needed. You can also keep it tight, but not too tight, so it works well. Lubricating the lathe parts can also help the belt last longer.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits For Metal Lathe Belts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on lathe repair kits for metal lathe belts: 1. What is a lathe repair kit? A lathe repair kit has tools and parts to fix a lathe. It helps you repair worn-out or broken belts. 2. Why do lathe belts need repairs? Lathe belts can wear out or break when used a lot. We need to fix or replace them to keep the lathe working well. 3. How do I know if my lathe belt needs repair? You can check the belt for cracks or tears. If it slips often, it might need repair too. 4. Can I fix the lathe belt myself? Yes, you can fix the lathe belt yourself! Use the repair kit and follow the instructions carefully. 5. Where can I buy a lathe repair kit? You can find lathe repair kits at hardware stores or online. Look for one that matches your lathe model.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide me with the specific question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That A Metal Lathe Belt Needs To Be Replaced Or Repaired?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a metal lathe belt needs fixing if it looks frayed or cracked. If it makes strange noises while running, it’s a sign too. Sometimes, the belt may slip or stop moving the machine correctly. If you see any of these signs, it’s time to check the belt.”}},{“@type”: “Question”,”name”: “How Do I Choose The Right Repair Kit For My Specific Model Of Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right repair kit for your metal lathe, first, check your lathe’s brand and model. Look for the repair kits made specifically for that brand and model. You can ask the store staff for help if you’re not sure. Read reviews or ask friends who have the same lathe. This way, you’ll find the best kit for your machine!”}},{“@type”: “Question”,”name”: “What Tools Are Typically Required To Install A New Lathe Belt From A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a new lathe belt, you usually need a few tools. First, grab a wrench to loosen the bolts. You also need a screwdriver to take off the cover. A pair of pliers can help pull and push the belt into place. Finally, make sure you have a clean cloth to wipe your hands and the lathe.”}},{“@type”: “Question”,”name”: “Are There Different Types Of Belts Available For Metal Lathes, And How Do I Determine Which Is Best For My Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are different types of belts for metal lathes, like flat belts and V-belts. To choose the best one, you need to check your machine’s manual. It will tell you the size and type of belt you need. You can also ask a shop expert for help. Make sure the belt fits right so your machine works well!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Belt?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help your metal lathe belt last longer, you should keep it clean. Dust and dirt can wear it down. Check it for cracks or damage often, and replace it when needed. You can also keep it tight, but not too tight, so it works well. Lubricating the lathe parts can also help the belt last longer.”}}]}