Have you ever wondered how metal lathes work? These machines shape metal with precision. But what happens when they need fixing? That’s where a lathe repair kit comes in handy!

A lathe repair kit can help you fix common issues quickly. Imagine being able to repair your metal lathe at home! This can save you time and money. Plus, you can get it back to work in no time.

With modern CAD design, creating a lathe repair kit becomes easier. You can design parts that fit perfectly. Have you ever tried creating something on a computer? It’s fun and lets you see your ideas take shape!

Many people don’t realize how important a lathe repair kit is in metalworking. A simple kit can bring your favorite tools back to life. So, let’s dive into the exciting world of lathe repair kits and CAD design!

Essential Lathe Repair Kit For Metal Lathe Cad Design

Lathe Repair Kit Metal Lathe CAD Design

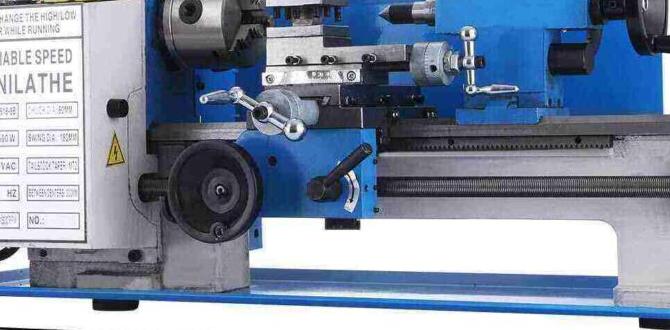

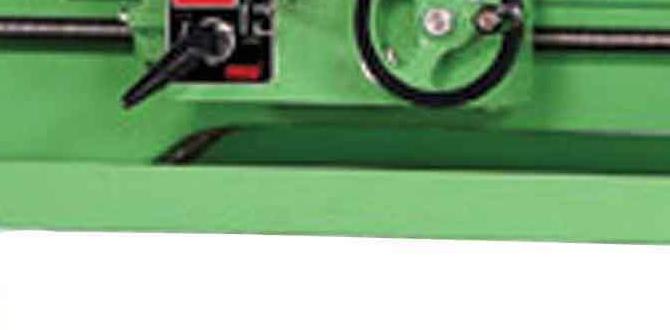

When your metal lathe needs a fix, having the right repair kit is crucial. A lathe repair kit helps keep your machine running smoothly. It includes essential tools and parts designed specifically for your lathe model. Have you ever thought about how computer-aided design (CAD) can improve your lathe repairs? Using CAD for design adds precision, making repairs easier and more efficient. This combination can save time and money, ensuring your lathe remains a reliable tool in your workshop. Explore the possibilities of integrating CAD in your lathe repair process!The Importance of Lathe Repair Kits

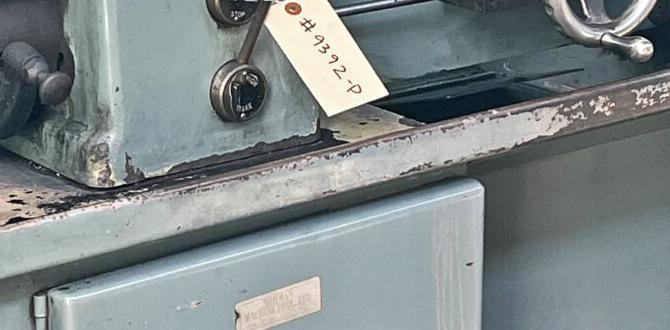

Common issues faced by metal lathes requiring repair. Benefits of having a dedicated repair kit.Metal lathes face common problems like worn bearings, loose belts, and misalignment. These issues can slow down your work or ruin a project. Having a lathe repair kit is like having a superhero sidekick. It helps you quickly fix problems without searching for tools every time. With a dedicated kit, you save time and avoid frustration. Plus, who wants to spend hours hunting for that one tiny screw? It’s the ultimate time-saver!

| Common Issues | Solution with Repair Kit |

|---|---|

| Worn bearings | Easy replacements keep things spinning smoothly. |

| Loose belts | Quick adjustments with the right tools. |

| Misalignment | Proper tools help you fix it right away! |

So, remember, a lathe repair kit is your best friend. It’ll help you tackle problems faster, giving you more time to be creative, or to binge-watch your favorite show!

Essential Components of a Lathe Repair Kit

List of musthave tools and parts in a repair kit. Materials and specifications for durable kit components.Every lathe repair kit needs some top-notch tools and parts. These are the superheroes of any rescue mission! First up, you want a good spindle bearing for smooth turns and spins. Don’t forget a tailstock assembly to keep everything in line! A set of cutting tools is essential too—after all, who doesn’t love a sharp edge?

Choose materials like steel for toughness and rubber for grip. This combo makes your kit last longer, even during wild projects. After all, a durable kit is like a trusty sidekick—always ready for action!

| Component | Material | Specifications |

|---|---|---|

| Spindle Bearing | Steel | High-precision, low friction |

| Tailstock Assembly | Aluminum | Lightweight, strong |

| Cutting Tools | High-speed Steel | Hard, accurate cutting |

Remember, a well-equipped lathe repair kit can save the day (and maybe a few headaches)!

Step-by-Step Guide to Designing a Lathe Repair Kit in CAD

Workflow of creating a CAD model for each component. Tips for optimizing designs for ease of use and repair efficiency.Creating a CAD model for a lathe repair kit is fun and straightforward. Start by designing each part separately. Use clear, simple shapes. This makes it easy to adjust later. Here’s a helpful workflow:

- Identify parts needed for repair.

- Sketch each component on paper.

- Use CAD software to create each part digitally.

- Check dimensions for accuracy.

- Keep design user-friendly for smooth repairs.

Designing with ease of use helps save time. Consider the best materials too. Strong materials can make repairs easier down the line.

What are the key points for optimizing designs?

Focus on simple shapes and clear layouts. Keep parts easy to replace. This allows quick fixes and better functionality.

Prototyping and Testing Repair Kit Designs

Methods for creating prototypes from CAD designs. Importance of testing and feedback in the design process.Creating prototypes from CAD designs is exciting! You can use materials like plastic or metal to build a working model. Make sure to check fit and design. Testing is key. It helps find problems early. Feedback from users is crucial for improvements. Keep these steps in mind:

- Build a simple model first.

- Test functionality and durability.

- Ask users for their opinions.

- Make changes based on feedback.

A good design can save time and money later.

Why is testing important for design?

Testing helps spot issues before the final product is made. It’s better to fix problems early. In fact, studies show that early testing can reduce costs by up to 30%!

Best Practices for Lathe Maintenance and Repair

Routine maintenance tips for metal lathes. How to effectively use the repair kit during maintenance tasks.To keep metal lathes in top shape, regular maintenance is key. Start by cleaning the machine often. Dust and chips can cause problems. Lubricate parts to prevent wear. Check bolts and screws to ensure they are tight. Additionally, using the lathe repair kit can help manage repairs easily.

When handling repairs, follow these tips:

- Use the right tools from the kit.

- Follow the manual for steps.

- Don’t rush; take your time.

With practice, your lathe can run smoothly for years.

How often should I perform maintenance on my lathe?

It is best to perform maintenance on your lathe at least once a week. This helps catch issues early and keeps the machine running well. Regular checks can save you time and money in repairs later on.

Case Studies of Successful Lathe Repair Kit Designs

Examples of innovative repair kits and their impact on lathe longevity. Lessons learned from realworld applications of various kits.Many inventors have designed clever repair kits that keep lathes running longer. For example, one kit included special seals that prevented oil leaks. This small change saved machines from breaking down. Another kit combined tools and a guide for easy fixes. Keeping lathes in good shape increases their lifespan and productivity.

From these real-world cases, we learn two things: first, simple fixes often have huge effects, and second, it’s important to customize repair kits for different lathes. A well-made kit can be like a superhero for machines!

| Repair Kit | Innovation | Impact |

|---|---|---|

| Seal & Repair Kit | Special seals to prevent leaks | Reduced breakdowns |

| All-in-One Kit | Tools with a user guide | Enhanced ease of use |

Future Trends in Lathe Repair Kit Designs

Emerging technologies and materials in lathe maintenance. Predictions for the evolution of CAD design in repair tools.Exciting changes are coming in the world of lathe repair kits! New materials like advanced composites and smart metals are making repairs quick and easy, as they’re lighter and stronger. Also, CAD (Computer-Aided Design) technology is about to get a makeover. In the future, repair tools will be designed with even better precision and efficiency. Imagine tools that can predict when they need fixing—like a lathe with a crystal ball! Here’s a quick look at these trends:

| Trend | Description |

|---|---|

| Smart Materials | Materials that change properties based on conditions, making repairs easier. |

| Advanced CAD Tools | Better designs that offer improved accuracy for repair kits. |

| Predictive Maintenance | Tools that alert you when they need repairs before they break. |

With these innovations, lathe maintenance will be smoother than a freshly oiled machine. Who knew repairs could be this fun?

Conclusion

In conclusion, a lathe repair kit is essential for keeping your metal lathe running smoothly. CAD design helps you visualize improvements easily. Understanding these tools can save you time and money. If you’re interested, explore more about lathe maintenance online. This knowledge can enhance your skills and projects. Start researching today, and enjoy crafting with a well-maintained lathe!FAQs

What Essential Components Should Be Included In A Lathe Repair Kit For A Metal Lathe?A lathe repair kit should have several important tools. You need wrenches to tighten and loosen parts. Screwdrivers help fix screws on the lathe. You should also include oil to keep it running smoothly. Lastly, extra belts can replace broken ones when needed.

How Can Cad Software Be Utilized To Design A Customized Lathe Repair Kit That Meets Specific Machine Requirements?You can use CAD software to create a special design for a lathe repair kit. First, you gather details about your lathe, like its size and parts. Then, you use the software to draw each part of the repair kit. This way, you can make sure everything fits perfectly and works well. Finally, you can print your design so you know exactly what to make or buy.

What Are The Best Practices For Designing Lathe Replacement Parts In Cad To Ensure Compatibility And Precision?When designing lathe replacement parts in CAD, you should always measure the old part first. This helps you get the right size. Use clear shapes and simple lines so it’s easy to see. Check your design by running tests in the software. Finally, save your work in different formats to share with others easily.

How Can Printing Technology Be Integrated Into The Production Of Components In A Lathe Repair Kit?We can use printing technology to make parts for a lathe repair kit. First, we design the parts on a computer. Then, we use a 3D printer to create them. This makes it faster and cheaper to get the pieces we need. You can also create custom parts that fit perfectly.

What Factors Should Be Considered When Selecting Materials For Lathe Repair Parts In Cad Design To Ensure Durability And Performance?When you pick materials for lathe repair parts in CAD design, think about strength first. You want parts that won’t break easily. Check if the material can handle heat and pressure well. It’s also important to choose something that won’t rust or wear out quickly. Finally, make sure it’s easy to find and affordable.