If you’ve ever used a metal lathe, you know how important it is to keep it in great shape. Have you ever wondered what happens when the control panel stops working? It can be frustrating, right? But don’t worry! A lathe repair kit can help fix those problems.

Many hobbyists and professionals rely on metal lathes for their projects. These machines help create parts and tools that need to be precise. However, even the best machines sometimes need repairs. That’s where the lathe repair kit comes in handy.

Imagine you’re in the middle of a project. Suddenly, the control panel goes blank. It feels like your work is stuck in time. With a lathe repair kit designed for control panels, you can get back to work quickly and easily.

Did you know that a well-maintained lathe can last for decades? Keeping it in good condition means knowing when to make repairs. A lathe repair kit can be your best friend in this journey.

Let’s dive into the world of lathe repair kits and learn how to keep your metal lathe running smoothly!

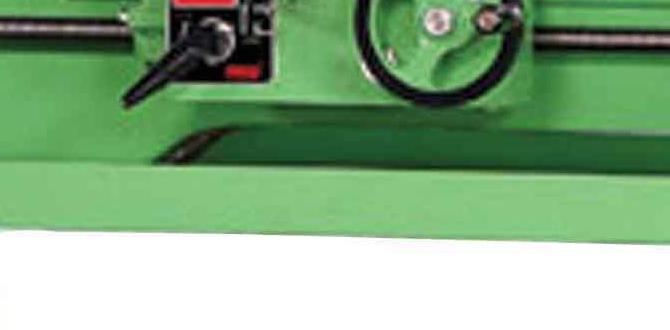

Essential Lathe Repair Kit For Metal Lathe Control Panel

Lathe Repair Kit for Metal Lathe Control Panels

A lathe repair kit is essential for keeping metal lathe control panels in top shape. These kits typically include handy tools and parts for quick fixes. Do you know that a small adjustment can save you from costly repairs? Many users find that having a repair kit on hand helps them avoid downtime. It’s like having a toolbox magical for metalworking! Staying prepared makes all the difference in keeping your lathe running smoothly.Understanding Lathe Repair Kits

Definition and purpose of lathe repair kits. Importance of maintenance for metal lathes.Lathe repair kits are tools to fix and maintain metal lathes. These kits help keep machines working smoothly. Without them, lathes can break down often, which can be very costly. Regular maintenance is important because it extends the life of your machine, saving time and money in the long run.

- Prevents machine breakdowns.

- Improves performance.

- Ensures safety.

Why are lathe repair kits important?

Lathe repair kits are crucial for keeping your metal lathe efficient and safe. Regular maintenance helps avoid bigger repairs later. It makes your projects easier and helps you work faster.

Components of a Typical Lathe Repair Kit

Essential tools and parts included in the kit. Specifications for compatibility with different metal lathes.A lathe repair kit holds key tools and parts to fix your metal lathe. It typically includes:

- Wrenches for adjusting parts.

- Screws and nuts for replacements.

- Bearings for smooth operation.

- Seals to prevent leaks.

- Lubricants for maintenance.

Each kit is made to fit various metal lathes. Check specifications to match your model. Proper compatibility ensures effective repairs and longer machine life.

What tools are in a lathe repair kit?

A lathe repair kit contains essential tools like screws, nuts, wrenches, and lubricants. These tools help keep your lathe running smoothly and prevent future issues. Always check compatibility with your machine.

Signs Your Control Panel Needs Repair

Common symptoms of malfunctioning control panels. Diagnostic tips for identifying issues.Having trouble with your control panel? Watch for these signs to spot trouble early! If buttons stick or lights flicker, it’s time for a peek. Weird noises might mean it’s throwing a tantrum, while error messages could be like the panel’s way of saying it needs help. Always start by checking connections and fuses. Think of it as giving your panel a relaxing spa day! Here’s a quick list to help you diagnose:

| Symptoms | What It Means |

|---|---|

| Sticking buttons | Needs cleaning or replacement |

| Flashing lights | Power issue or short circuit |

| Strange noises | Mechanical failure approaching |

| Error messages | Time for a repair kit! |

Address these symptoms ASAP, and keep your lathe running smoothly. After all, no one wants a grumpy machine!

Step-by-Step Guide to Repairing Your Metal Lathe Control Panel

Preparation steps before starting the repair. Detailed instructions for common repairs.Before you start fixing your metal lathe control panel, it’s important to get ready. First, unplug the machine for safety. Gather your tools, like screwdrivers and your lathe repair kit. Next, check for any visible damage and take notes. This helps you focus on what needs fixing. Remember to clean the area so you can work without distractions.

- Unplug the machine.

- Gather tools and the repair kit.

- Inspect the panel for damage.

- Clean your workspace.

Now you’re ready to make some common repairs. These may include replacing buttons or fixing loose wires. Check each part carefully. If something is broken, you can often find a replacement in your repair kit.

What are common repairs for a metal lathe control panel?

Common repairs include replacing broken buttons, fixing loose wires, and cleaning connections.

Steps for common repairs:

- Replace broken buttons by unscrewing the old one and attaching a new one.

- Tighten loose wires and ensure they are secure.

- Clean dust and debris from connections to improve performance.

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Comparisons of popular brands and kits available.Selecting the right lathe repair kit can be tricky. Here are some key points to help you decide:

- Compatibility: Ensure the kit matches your lathe model.

- Quality: Look for kits made from durable materials.

- Brand Reputation: Some brands are known for better performance.

Popular kits include brands like Jet and Grizzly, each offering unique features. Read reviews to find what others like best.

What factors should I consider when buying a lathe repair kit?

Consider compatibility, quality materials, and brand reputation. These factors affect how well the kit works with your lathe.

Preventive Maintenance for Longevity

Best practices to extend the lifespan of your lathe control panel. Recommended maintenance schedules and checklists.Taking care of your lathe control panel helps it work better and last longer. Regular maintenance keeps parts running smoothly. Here are some best practices:

- Clean dust and debris regularly.

- Check for loose wires each month.

- Inspect buttons and knobs for wear and tear.

- Lubricate moving parts every six months.

Using a checklist can help remember these tasks. Following them can make your lathe control panel last for years.

How often should I maintain my lathe control panel?

It is best to check your lathe control panel monthly for dirt and wear, and perform major maintenance every six months. This keeps everything in great shape and helps avoid problems.

FAQs About Lathe Repair Kits

Common questions and expert answers. Troubleshooting tips for users.Many people have questions about lathe repair kits. Here are some common ones:

What is included in a lathe repair kit?

A typical kit includes essential tools and parts like belts, bearings, and switches. These help fix or upgrade the lathe easily.

How do I know when my lathe needs repair?

If you hear strange noises or see uneven cuts, it’s time to check your lathe. Regular maintenance can prevent bigger issues.

What are some troubleshooting tips?

- Check the power supply if the lathe won’t turn on.

- Inspect belts and gears for wear or damage.

- Keep the control panel clean to avoid malfunction.

Additional Resources and Support

Where to find detailed repair manuals and guides. Recommended forums and communities for metal lathe enthusiasts.Finding help for a lathe can be easy! Look for repair manuals and guides online. Websites like Machinery’s Handbook offer detailed instructions. You can also visit forums where metal lathe lovers chat. It’s a great place to learn and get advice.

- Reddit – r/metalworking: A community sharing tips and tricks.

- Lathes.co.uk: An excellent resource for guides and manuals.

- Facebook Groups: Join groups dedicated to metal lathes.

These resources can help you understand your metal lathe better!

Where can I find repair manuals for metal lathes?

You can find repair manuals on websites like Machinery’s Handbook and Lathes.co.uk. These sites provide valuable guides for lathe maintenance and repair.

Conclusion

In summary, a lathe repair kit for your metal lathe’s control panel is essential for smooth operation. It helps fix problems quickly and keeps your machine running well. You can find kits online or at hardware stores. If you’re curious, consider learning more about lathe maintenance. With the right tools, you can ensure your projects are successful and enjoyable!FAQs

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Control Panel?A lathe repair kit for the control panel usually includes buttons, switches, and fuses. You might also find wires and connectors. Sometimes, there are tools to help you fix things. Each part helps the lathe work better.

How Can I Diagnose Issues With The Control Panel Of My Metal Lathe Before Using A Repair Kit?To diagnose problems with the control panel of your metal lathe, start by checking the power. Make sure it’s plugged in and the switch is on. Look for any loose wires or connections that might be disconnected. You can also press buttons to see if they work. If something seems broken or isn’t working right, note it down before using the repair kit.

What Is The Process For Installing A New Control Panel In A Metal Lathe Using A Repair Kit?To install a new control panel on a metal lathe, you start by unplugging the machine. Then, you take off the old control panel by unscrewing it. Next, you connect the wires from the new panel. After that, you screw the new panel into place and plug the machine back in. Finally, you test the new panel to make sure it works!

Are There Specific Brands Or Models Of Metal Lathes That Have Commonly Used Repair Kits For Their Control Panels?Yes, some brands of metal lathes often have repair kits for their control panels. Popular brands include Grizzly, Jet, and South Bend. These brands are used by many people, so their parts are easier to find. If you have one of these lathes, you can check their websites for repair kits.

What Safety Precautions Should Be Taken When Repairing Or Replacing The Control Panel On A Metal Lathe?When fixing the control panel on a metal lathe, you need to be careful. First, always unplug the lathe to stop it from working. Next, wear safety gloves to protect your hands. Also, use goggles to keep your eyes safe from any flying pieces. Finally, make sure the work area is clean so you don’t trip or hurt yourself.