Have you ever wondered how metal lathes keep running smoothly? A lathe is a powerful tool that helps create amazing shapes from metal. But like any machine, it needs care and attention. That’s where a lathe repair kit comes in. This kit is essential for fixing problems that pop up during use.

One key part of maintaining a metal lathe is coolant. Coolant helps keep the machine cool while it works. It also helps to make the cuts smoother. Without it, your lathe might overheat or get damaged. Imagine trying to ride your bike with a flat tire. It just won’t work well! The same goes for a lathe without coolant.

Regular maintenance with the right lathe repair kit can save you time and money. Think about it: how frustrating would it be if your lathe breaks down in the middle of an important project? By using a lathe repair kit and proper coolant, you can avoid stress and keep your projects on track. So, let’s explore how these tools can make your metalworking dreams come true!

Essential Lathe Repair Kit: Metal Lathe Coolant Solutions

Understanding Lathe Repair Kit and Metal Lathe Coolant

A lathe repair kit can make a big difference in your metalworking tasks. Have you ever tried to fix a lathe? It’s crucial for keeping your machine running smoothly. The right coolant plays a vital role too. It helps reduce heat and friction during cutting. Did you know that the right coolant can even extend the life of your tools? This knowledge can save you time and money, making your metal projects easier and more efficient.Understanding Lathe Repair Kits

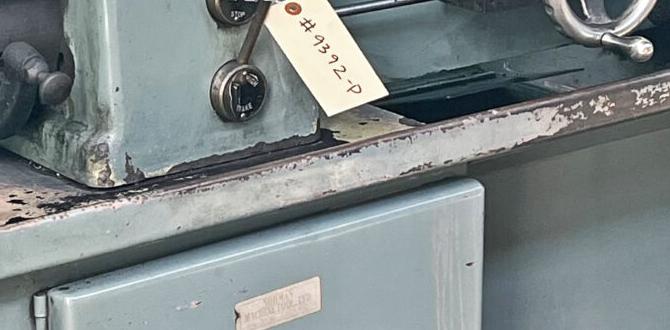

Definition and purpose of lathe repair kits. Common components included in repair kits.Lathe repair kits are special sets of tools and parts used to fix lathes. These kits help keep machines running smoothly. They usually include items like bearings, seals, and gaskets. Using a repair kit can save time and money. It helps avoid big problems that can stop work.

- Bearings: Help the lathe move smoothly

- Seals: Keep oil and coolant inside

- Gaskets: Ensure a tight fit between parts

These components are needed for regular checks and repairs. Having a lathe repair kit means you are ready for any fix!

What is the purpose of a lathe repair kit?

The purpose of a lathe repair kit is to provide essential tools and parts for maintenance. It helps to fix common issues quickly and keeps the lathe running well.

Types of Lathe Repair Kits

Standard vs. specialized lathe repair kits. Key features to look for in a repair kit.There are two main types of lathe repair kits: standard and specialized. Standard kits usually contain basic parts for general repairs, while specialized kits have items for specific lathe models or unique needs. Think of a standard kit as a trusty toolbox, perfect for simple fixes. Meanwhile, a specialized kit is like a superhero costume—designed for very special missions! Key features to look for include quality parts, clear instructions, and a handy storage case. Remember, the right kit can keep things spinning smoothly!

| Type | Best For | Key Features |

|---|---|---|

| Standard Kit | General repairs | Basic parts, easy instructions |

| Specialized Kit | Specific models | Unique parts, clear guidance |

The Importance of Metal Lathe Coolant

Role of coolant in metal lathe operations. Types of metal lathe coolants available in the market.Coolant is like a superhero for metal lathes. It keeps things cool and happy during tough work. Without it, metal can heat up, warp, or even create tiny flying metal bits. There are different types of coolants on the market. Some coolants are water-based, while others are oil-based. Each type has its own superpower! Using the right coolant can help your lathe last longer and work better. Below is a quick comparison of common coolants:

| Type of Coolant | Best For |

|---|---|

| Water-Based | General work and cooling |

| Oil-Based | Heavy-duty tasks |

| Synthetic | Metalworking without mess |

Remember, the right coolant can make your lathe happier than a cat in a sunshine pool!

Choosing the Right Coolant for Your Lathe

Factors to consider when selecting coolant. Comparison of synthetic, semisynthetic, and soluble coolants.Choosing a coolant is important for your lathe. Several factors matter. Think about the type of material you are machining. Synthetic, semi-synthetic, and soluble coolants all have their benefits. Synthetic coolants last longer but may cost more. Semi-synthetic coolants mix oil and water. They offer good cooling without being too messy. Soluble coolants are easy to use and affordable. Compare these types to find what works best for you.

What should I consider when choosing a coolant?

You should think about:

- Type of material

- Cost

- Cooling performance

- Messiness

- Health safety

Step-by-Step Guide to Maintaining Your Lathe

Routine maintenance practices. When to use repair kits and coolant.Keeping your lathe in top shape is easy with routine care. Regularly check the machine for dust and chips. Clean the surfaces to ensure smooth operation. Use a lathe repair kit to fix minor issues. This can save time and money later. It’s important to use coolant when cutting metal. This keeps the lathe cool and prolongs its life.

When should you use a lathe repair kit and coolant?

You should use a lathe repair kit when you notice unusual sounds or vibrations. Coolant is essential during heavy machining to prevent overheating.

- Check for wear after every few uses.

- Apply coolant whenever cutting metal.

Simple checks can help prevent big problems. Keep your lathe well-maintained and it will serve you well for years!

Common Issues and Solutions in Lathe Operations

Identifying wear and tear in lathe components. Troubleshooting coolantrelated problems.Lathe machines can sometimes be a bit moody. Signs of wear and tear, like strange noises or uneven cuts, can pop up faster than a jack-in-the-box. Regular checks on key parts, such as bearings and belts, can help spot trouble before it strikes. As for coolant issues, blocked lines can make your machine hotter than a summer day. Keeping an eye on fluid levels and cleaning the system regularly can solve most problems. Remember, a happy lathe means happy projects!

| Issue | Solution |

|---|---|

| Uneven cuts | Check tool sharpness and alignment |

| Strange noises | Inspect bearings and belts |

| Blocked coolant lines | Clean lines and check fluid levels |

Where to Buy Lathe Repair Kits and Coolant

Recommended online retailers and local suppliers. Factors to consider when purchasing.Shopping for lathe repair kits and coolant can be a breeze, or it can feel like searching for a needle in a haystack. First, try reputable online retailers like Amazon or eBay. They often have great deals and fast shipping. Don’t forget local hardware stores! You might discover hidden gems right in your neighborhood.

When buying, consider quality over price. It’s better to spend a few extra bucks on something that lasts. Check reviews too. A product that everyone raves about is usually a safe bet!

| Retailer | Type | Notes |

|---|---|---|

| Amazon | Online | Wide selection and fast shipping. |

| eBay | Online | Good deals, but check seller ratings. |

| Your Local Hardware Store | Local | Personal service and immediate access. |

In a nutshell, choose where you shop wisely, and your projects will run smoother than a kid on a skate ramp!

Cost Analysis of Lathe Repair Kits and Coolants

Average prices of different types of kits and coolants. Costsaving tips for lathe maintenance.The price of lathe repair kits and coolants can vary greatly. A basic repair kit might cost around $50, while high-end options can reach $200. Coolants usually range from $10 to $50 per gallon. To save money on lathe maintenance, consider these tips:

- Buy kits in sets to reduce costs.

- Look for discounts or sales on supplies.

- Maintain your lathe regularly to avoid expensive repairs.

What are average prices for lathe repair kits and coolants?

The average price of lathe repair kits is $50 to $200, while coolants typically cost $10 to $50 per gallon.

Conclusion

In conclusion, a lathe repair kit helps maintain your metal lathe and keeps it running smoothly. Using the right coolant prevents overheating and improves cutting performance. Remember to check your kit regularly and replace worn parts. For more tips on lathe maintenance, explore articles online or ask experienced friends for advice. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kit For Metal Lathes And Coolant:A lathe repair kit helps you fix parts of a metal lathe. It usually includes tools and spare pieces. You can use it to make your lathe work better. Coolant helps keep the lathe cool and running smoothly. It also stops metal from getting too hot when you use it.

Sure! Please provide the question you would like me to answer.

What Essential Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?A lathe repair kit for metal lathes usually includes some important tools. You might find wrenches to tighten parts. There are also gears and belts that help the machine work smoothly. Small screws and bolts hold things together. Finally, you’ll see oil or grease to keep everything running well.

How Do You Determine The Right Type Of Coolant For Different Metalworking Applications On A Lathe?To choose the right coolant for a lathe, you need to think about the metal you’re working with. Some metals get hot quickly, needing coolants that cool them well. You should also consider if you want a liquid or a spray. Finally, try a small amount first to see how well it works before using it on the whole project.

What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe And Its Coolant System?To make your metal lathe last longer, keep it clean by wiping off dust and metal shavings. Check for rust and oil it regularly to keep it running smoothly. Make sure the coolant system has enough liquid and check for leaks often. In addition, change the coolant when it gets dirty so it works well. Lastly, always follow the user manual for tips on caring for your lathe.

Are There Any Signs That Indicate The Need For Repairs In A Metal Lathe’S Coolant System?Yes, there are signs that show a metal lathe’s coolant system needs repairs. If you see leaks or puddles under the machine, that’s a problem. You might also notice strange noises or the coolant smells bad. If the coolant isn’t flowing well or looks dirty, it might need fixing too. Keeping an eye on these signs helps us catch issues early!

How Can Improper Coolant Use Affect The Performance And Longevity Of A Metal Lathe?Using the wrong coolant in a metal lathe can cause problems. If the coolant is dirty or the wrong type, it won’t cool the machine properly. This can make the lathe parts wear out faster. It can also cause rust or damage to the metal. If you use the right coolant, your lathe will last longer and work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kit For Metal Lathes And Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit helps you fix parts of a metal lathe. It usually includes tools and spare pieces. You can use it to make your lathe work better. Coolant helps keep the lathe cool and running smoothly. It also stops metal from getting too hot when you use it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Essential Components Are Typically Included In A Lathe Repair Kit For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for metal lathes usually includes some important tools. You might find wrenches to tighten parts. There are also gears and belts that help the machine work smoothly. Small screws and bolts hold things together. Finally, you’ll see oil or grease to keep everything running well.”}},{“@type”: “Question”,”name”: “How Do You Determine The Right Type Of Coolant For Different Metalworking Applications On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right coolant for a lathe, you need to think about the metal you’re working with. Some metals get hot quickly, needing coolants that cool them well. You should also consider if you want a liquid or a spray. Finally, try a small amount first to see how well it works before using it on the whole project.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe And Its Coolant System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your metal lathe last longer, keep it clean by wiping off dust and metal shavings. Check for rust and oil it regularly to keep it running smoothly. Make sure the coolant system has enough liquid and check for leaks often. In addition, change the coolant when it gets dirty so it works well. Lastly, always follow the user manual for tips on caring for your lathe.”}},{“@type”: “Question”,”name”: “Are There Any Signs That Indicate The Need For Repairs In A Metal Lathe’S Coolant System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are signs that show a metal lathe’s coolant system needs repairs. If you see leaks or puddles under the machine, that’s a problem. You might also notice strange noises or the coolant smells bad. If the coolant isn’t flowing well or looks dirty, it might need fixing too. Keeping an eye on these signs helps us catch issues early!”}},{“@type”: “Question”,”name”: “How Can Improper Coolant Use Affect The Performance And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the wrong coolant in a metal lathe can cause problems. If the coolant is dirty or the wrong type, it won’t cool the machine properly. This can make the lathe parts wear out faster. It can also cause rust or damage to the metal. If you use the right coolant, your lathe will last longer and work better.”}}]}