Have you ever experienced a hiccup while using your metal lathe? It can be quite frustrating. A lathe repair kit might be just the solution you need. It’s surprising how quickly small problems can turn into big ones when machines aren’t maintained properly.

Imagine working on a project only to find your lathe is not cutting as it should. This is where good maintenance comes in. A lathe repair kit is essential for keeping your machine in top shape. With the right tools and a little know-how, you can tackle most issues.

Fun fact: many hobbyists don’t realize that regular maintenance can extend the life of their lathe. Simple checks can save time and money. So, why wait? Dive into the world of lathe maintenance and discover how a repair kit can keep your machine running smoothly.

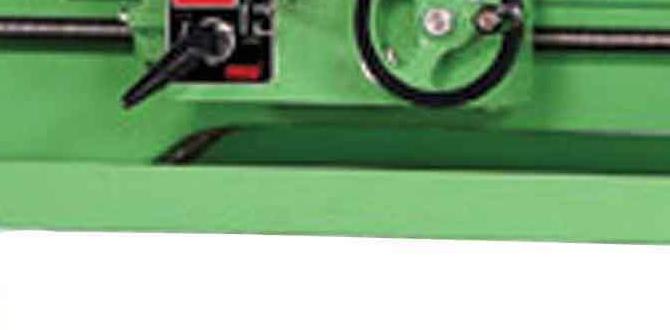

Essential Lathe Repair Kit For Effective Metal Lathe Maintenance

Lathe Repair Kit & Metal Lathe Maintenance

A lathe repair kit is essential for any metal lathe owner. These kits help you keep your machine running smoothly. Simple maintenance can save you money in the long run. Ever think about how a tiny part can cause big problems? Regular checks can prevent breakdowns. For example, changing the oil and cleaning parts keeps your lathe in top shape. Discover tips to use your lathe longer and better with proper care!Signs Your Lathe Needs Repair

Common symptoms of wear and tear. Importance of timely repairs for optimal performance.Watch for signs that your lathe might need repair. Worn parts can affect how it works. Here are some common signs you might notice:

- Unusual noises when running

- Vibrations or wobbling during use

- Inconsistent cuts on materials

- Difficulty turning the machine on or off

Taking care of repairs quickly is important. Timely fixes can keep your lathe running smoothly and help you avoid bigger problems later.

What are the signs your lathe needs attention?

Look for unusual noises or vibrations. These could be signs of wear. Fixing issues early can save you money and time.

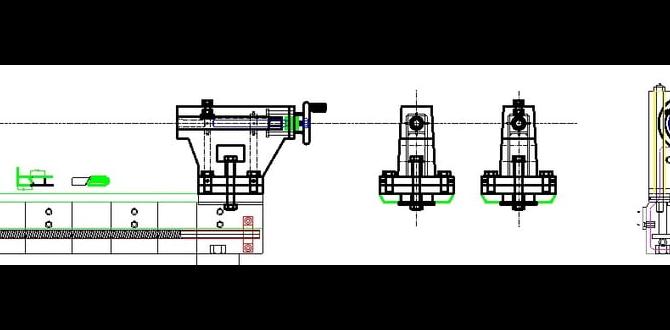

Components of a Lathe Repair Kit

Essential tools included in a repair kit. Replacement parts and their significance.A lathe repair kit is key for keeping your metal lathe in good shape. It includes important tools and parts that help fix and maintain the machine. Here are the main components:

- Essential Tools: Wrenches, screwdrivers, and pliers are crucial for adjustments.

- Replacement Parts: Bearings and belts help the lathe run smoothly. Without them, the machine can break down.

Having a complete kit ensures quick repairs and less downtime. Regular maintenance keeps your lathe working efficiently.

What tools are in a lathe repair kit?

The main tools include wrenches, screwdrivers, and pliers. These help in making quick fixes and adjustments.

Why are replacement parts important?

Replacement parts maintain your lathe’s performance. They prevent breakdowns and extend the machine’s life.

Selecting the Right Repair Kit for Your Lathe

Factors to consider when choosing a repair kit. Comparison of popular brands and their kits.Selecting a repair kit for your lathe can be challenging. You should think about several factors. First, check the quality of the parts. Next, consider how easy it is to use the kit. Price is also important, but don’t compromise quality for cost. Some popular brands are:

- Brand A: Known for durability and excellent customer support.

- Brand B: Offers great value, but some parts might wear faster.

- Brand C: Ideal for beginners, with easy-to-follow instructions.

Remember, the right kit can make maintenance fun and effective!

What should I look for in a lathe repair kit?

Look for quality parts, ease of use, and customer support. A good kit can save money and time. Read reviews to ensure you choose wisely.

Step-by-Step Guide to Lathe Maintenance

Daily maintenance tasks for longevity. Monthly and annual maintenance checks.Keeping your lathe in top shape requires regular care. Daily tasks are simple but vital, like cleaning chips and checking oil levels. Monthly, look for wear and tear on belts and clamps. Annually, inspect gears and bearings. This routine helps your lathe last longer and work better.

- **Daily Tasks:** Clean workspace, check oil, tighten loose parts.

- **Monthly Tasks:** Inspect belts, adjust alignment, test switches.

- **Annual Tasks:** Check bearings, lubricate gears, and replace worn parts.

What are daily maintenance tasks for a lathe?

The daily care for your lathe includes cleaning the machine, checking oil levels, and tightening any loose parts. This simple routine enhances performance and helps avoid issues.

How often should you perform maintenance checks on a lathe?

Monthly checks should include inspecting belts and calibrating settings. You should perform annual checks for gears and bearings. Following this schedule improves your lathe’s lifespan.

How to Use a Lathe Repair Kit

Detailed instructions for common repairs. Safety precautions while using a repair kit.Using a lathe repair kit can be simple and effective. Start by identifying the repair needed. Common repairs include replacing belts and bearings. Follow these steps for safety and success:

- Wear safety goggles to protect your eyes.

- Ensure the lathe is powered off before starting any work.

- Read the instructions in the repair kit carefully.

- Use the right tools for each task.

With careful steps, your lathe can run smoothly again!

What are the benefits of a lathe repair kit?

A lathe repair kit saves money and time. It helps keep your lathe in good condition, which leads to better performance. Regular maintenance prevents costly problems later on.

Tips for Preventing Lathe Repairs

Best practices for maintaining your lathe. Importance of routine inspections and upkeep.Taking care of your lathe is like giving it a cozy blanket and a warm cup of tea! Regular checks can catch problems before they grow. Make a schedule to inspect all parts. Lubricate the moving pieces to keep things smooth. Remember, a healthy lathe makes better parts. Routine maintenance can save you money on repairs later. A happy lathe works harder for you – kind of like a loyal dog, minus the barking!

| Tip | Description |

|---|---|

| Check the Lubrication | Ensure all moving parts are well-lubricated to prevent wear. |

| Regularly Inspect | Look for any signs of damage or wear during routine checks. |

| Keep it Clean | Remove dust and debris to extend the lathe’s life. |

Cost-Effectiveness of Regular Maintenance and Repair Kits

Analyzing the cost benefits of investing in repair kits. Comparison of repair costs versus replacement costs.Maintaining your lathe can save you money in the long run. Think of it this way: spending a little on a repair kit can beat the high costs of replacing your entire machine. Regular upkeep can extend the life of your lathe and keep it running smoothly, making you the hero of your workshop. Who wouldn’t want to save money and impress their friends at the same time?

| Cost Type | Estimated Cost |

|---|---|

| Repair Kit | $50 – $200 |

| Replacement Lathe | $1,000 – $5,000 |

In fact, studies show that regular maintenance can cut repair costs by up to 30%. Investing in repair kits can be a smart move. It’s like putting money in your piggy bank instead of throwing it away!

Frequently Asked Questions about Lathe Maintenance and Repair Kits

Addressing common inquiries from users. Expert tips for maintaining performance and efficiency.Lathe maintenance can be confusing. Many users have questions about how to keep their machines running smoothly. Here are some common inquiries:

How often should I grease my lathe?

Greasing your lathe every few months is ideal. This helps keep the parts moving freely. Regular checks keep everything in top shape.

What tools do I need for basic repairs?

A simple repair kit with wrenches, screwdrivers, and an oil can is enough. These tools help with common problems. Always be prepared for small fixes!

How can I improve my machine’s efficiency?

Regular cleaning and lubrication are key. This reduces wear and tear. Be careful with settings and choose the right speed for your materials.

- Check belts and gears for wear.

- Inspect the power supply.

- Keep the lathe surface clean.

Keeping these tips in mind will help you maintain your lathe repair kit metal lathe maintenance effectively!

Conclusion

In summary, a lathe repair kit is essential for keeping your metal lathe in top shape. Regular maintenance ensures your machine works smoothly and lasts longer. You can save money by fixing problems early. Start by exploring simple repair techniques today. For more tips and detailed guides, check out resources online to become a lathe maintenance pro!FAQs

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe?A lathe repair kit for a metal lathe usually includes several important tools and parts. You might find wrenches for tightening and loosening screws. There are also belts to help the lathe run smoothly. Sometimes, it has bearings that keep things moving perfectly. Lastly, you may get some screws and small parts to fix anything that’s broken.

How Often Should Routine Maintenance Be Performed On A Metal Lathe To Ensure Optimal Performance?You should do routine maintenance on a metal lathe every few months. This helps keep it running well. Check for wear and tear each time you use it. Clean it and oil the moving parts regularly. If you notice any problems, fix them right away to keep everything working smoothly.

What Are The Most Common Issues That Require Repair On A Metal Lathe, And How Can They Be Addressed Using A Repair Kit?Common problems with metal lathes include worn parts, loose belts, and damaged tools. You can fix worn parts by replacing them with new ones from a repair kit. Loose belts can be tightened easily to make sure they work well. For damaged tools, you can replace them with fresh ones from the kit. This way, your lathe will run smoothly again!

Can You Provide A Step-By-Step Guide For Using A Lathe Repair Kit To Fix A Specific Issue, Such As A Misaligned Bed Or Worn Bearings?Sure! Here’s a simple guide to fix a misaligned lathe bed using a repair kit. 1. First, turn off the lathe and unplug it for safety. 2. Look for the screws that hold the bed in place. Use a screwdriver to loosen them. 3. Carefully adjust the bed until it lines up straight. 4. Tighten the screws back to hold the bed in place. 5. Finally, plug the lathe back in and test it out.

What Are Some Best Practices For Maintaining A Metal Lathe To Extend Its Lifespan And Minimize The Need For Repairs?To keep your metal lathe in great shape, clean it after each use. You should also oil the moving parts regularly to prevent rust. Check for loose bolts and tighten them if needed. Always use the right tools for each job to avoid damage. Finally, store it in a dry place to protect it from moisture.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for a metal lathe usually includes several important tools and parts. You might find wrenches for tightening and loosening screws. There are also belts to help the lathe run smoothly. Sometimes, it has bearings that keep things moving perfectly. Lastly, you may get some screws and small parts to fix anything that’s broken.”}},{“@type”: “Question”,”name”: “How Often Should Routine Maintenance Be Performed On A Metal Lathe To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should do routine maintenance on a metal lathe every few months. This helps keep it running well. Check for wear and tear each time you use it. Clean it and oil the moving parts regularly. If you notice any problems, fix them right away to keep everything working smoothly.”}},{“@type”: “Question”,”name”: “What Are The Most Common Issues That Require Repair On A Metal Lathe, And How Can They Be Addressed Using A Repair Kit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common problems with metal lathes include worn parts, loose belts, and damaged tools. You can fix worn parts by replacing them with new ones from a repair kit. Loose belts can be tightened easily to make sure they work well. For damaged tools, you can replace them with fresh ones from the kit. This way, your lathe will run smoothly again!”}},{“@type”: “Question”,”name”: “Can You Provide A Step-By-Step Guide For Using A Lathe Repair Kit To Fix A Specific Issue, Such As A Misaligned Bed Or Worn Bearings? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a simple guide to fix a misaligned lathe bed using a repair kit. 1. First, turn off the lathe and unplug it for safety. 2. Look for the screws that hold the bed in place. Use a screwdriver to loosen them. 3. Carefully adjust the bed until it lines up straight. 4. Tighten the screws back to hold the bed in place. 5. Finally, plug the lathe back in and test it out.”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Maintaining A Metal Lathe To Extend Its Lifespan And Minimize The Need For Repairs? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe in great shape, clean it after each use. You should also oil the moving parts regularly to prevent rust. Check for loose bolts and tighten them if needed. Always use the right tools for each job to avoid damage. Finally, store it in a dry place to protect it from moisture.”}}]}