Have you ever wanted to fix your own tools? If you own a metal lathe, you might find this exciting. A lathe repair kit can help you fix your metal lathe quill. This simple tool is vital for many projects. It shapes metal and creates parts with precision. But what happens when it doesn’t work right?

Imagine trying to finish a project, and your lathe stops working. Frustrating, isn’t it? You could spend a lot of money on repairs. But with a lathe repair kit, you can save time and money. You can tackle the repairs yourself!

Did you know that many people create their own repair kits? They mix and match tools to fit their needs. This means they can fix their lathes faster. Plus, they learn more about how their tools work. Isn’t that cool?

In this article, we’ll explore the best lathe repair kits for your metal lathe quill. You’ll learn how to choose the right one. Get ready to dive into the exciting world of lathe repair!

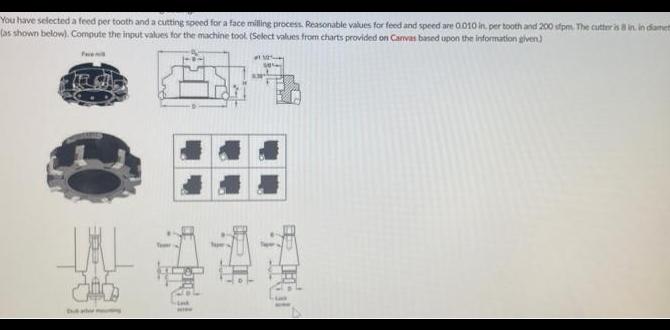

Essential Lathe Repair Kit For Metal Lathe Quill Maintenance **Introduction** In The World Of Metalworking, Maintaining Your Tools Is Crucial For Achieving Precision And Longevity. One Of The Most Essential Components Of A Metal Lathe Is The Quill, Which Requires Regular Maintenance And Repair To Ensure Optimal Performance. A Lathe Repair Kit Specifically Designed For The Metal Lathe Quill Can Make This Task Straightforward And Efficient. In This Article, We Will Explore What A Lathe Repair Kit Typically Includes, The Importance Of Quill Maintenance, And Tips For Selecting The Right Kit For Your Needs. **What Is A Lathe Repair Kit?** A Lathe Repair Kit Is A Collection Of Tools And Components Meant To Facilitate The Maintenance And Repair Of A Lathe, Particularly Focusing On The Quill, Which Is The Part Of The Lathe That Holds The Cutting Tool. The Quill Allows For Vertical Movement, Enabling Precise Adjustments During Machining Processes. Over Time, Wear And Tear Can Lead To Decreased Accuracy, Making It Essential To Have A Reliable Lathe Repair Kit On Hand. **Key Components Of A Metal Lathe Quill Repair Kit** When Selecting A Lathe Repair Kit For Your Metal Lathe Quill, Look For The Following Essential Components: 1. **Seals And Gaskets**: These Are Crucial For Preventing Oil Leaks And Maintaining Lubrication Within The Quill Mechanism. 2. **Bearings**: Over Time, Bearings Can Wear Out Or Become Damaged Due To Constant Use. A Good Kit Will Include Replacement Bearings To Ensure Smooth Operation. 3. **Collet Clamps**: These Are Necessary For Holding The Cutting Tools Securely In Place During Machining Operations. 4. **Adjustment Tools**: Often, The Kit Will Include Tools Specifically Designed For Making Precision Adjustments To The Quill. **Importance Of Regular Quill Maintenance** Regular Maintenance Of The Quill Is Essential For Several Reasons: – **Accuracy And Precision**: A Well-Maintained Quill Provides Better Accuracy And Precision In Metalworking Tasks, Leading To Higher Quality Finished Products. – **Extended Tool Life**: Taking Care Of Components Like The Quill Can Extend The Overall Life Of Your Metal Lathe, Saving You Money On Replacements In The Long Run. – **Safety**: A Malfunctioning Quill Can Pose Safety Risks During Operation. Regular Checks And Repairs Prevent Accidents And Injuries In The Workshop. **Tips For Choosing The Right Lathe Repair Kit** Investing In A Quality Lathe Repair Kit Is Important For Smooth Operations. Here Are Some Tips To Help You Choose The Right One: 1. **Compatibility**: Ensure That The Kit Is Compatible With Your Specific Model Of Metal Lathe To Avoid Issues During Installation. 2. **Quality Of Parts**: Look For Kits That Include High-Quality Components To Ensure Long-Lasting Performance. 3. **User Reviews**: Research User Feedback And Reviews To Gauge The Reliability And Effectiveness Of The Repair Kit You’Re Considering. **Conclusion** Having A Dedicated Lathe Repair Kit For Your Metal Lathe Quill Is Essential For Maintaining The Performance And Longevity Of Your Machine. By Understanding The Key Components Of These Kits, The Importance Of Quill Maintenance, And How To Select The Right Kit, You Can Ensure That Your Metalworking Projects Remain Precise And Efficient. Regular Upkeep Not Only Improves The Functionality Of Your Lathe But Also Enhances Your Overall Productivity In The Workshop.

Lathe Repair Kit for Metal Lathe Quill

When your metal lathe quill needs fixing, a lathe repair kit can save the day! These kits contain key parts such as bearings, seals, and tools designed for smooth repairs. Imagine how quickly you can return to your project with the right kit. Did you know that regular maintenance can extend your lathe’s life? Investing in a quality repair kit ensures you’re always ready for any issue that may pop up. Get prepared and keep your lathe in top shape!Understanding Metal Lathe Quills

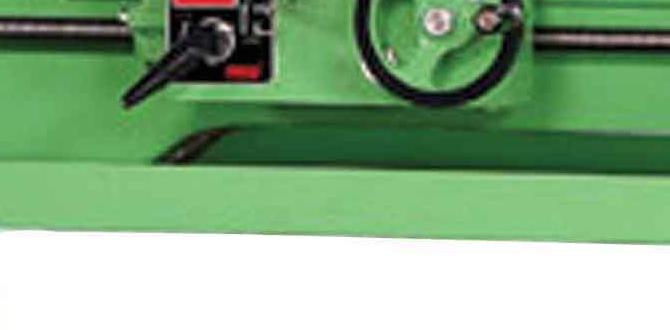

Definition and purpose of a quill in metal lathes. Common issues faced with lathe quills.A quill is a part of a metal lathe that helps to hold and move the cutting tool. It makes sure the tool works smoothly while shaping the metal. Without a quill, the cutting process can become messy and inaccurate. Some common problems with lathe quills include:

- Wear and tear over time

- Misalignment, causing uneven cuts

- Leaks or bad seals affecting performance

Understanding these issues can help you take better care of your lathe.

What is a quill in a metal lathe?

A quill is a tool holder that adjusts the cutting depth in a lathe. It ensures precise metal shaping during project work.

Why does a lathe quill malfunction?

Lathe quills often malfunction due to wear, dirt, and misalignment. Regular maintenance can solve most issues.

The Importance of a Lathe Repair Kit

Benefits of having a dedicated repair kit. Costeffectiveness of DIY repairs with a repair kit.A lathe repair kit is important for keeping your machine running smoothly. It saves time and money. With a dedicated kit, you can quickly fix small problems. This means you can get back to work faster. Plus, DIY repairs can be fun!

Here are some benefits of having a lathe repair kit:

- Helps you troubleshoot problems.

- Reduces costs on professional repairs.

- Empowers you to learn more about your machine.

DIY repairs are often cheaper than hiring someone. You can solve issues right away, so your metal lathe quill stays in top shape.

Why is a lathe repair kit useful?

A lathe repair kit is useful because it allows you to quickly fix issues and save money on repairs.What can you repair with a lathe kit?

- Quills and gears.

- Belts and bearings.

- Lubrication problems.

Having a repair kit means your lathe will always be ready to work. It also encourages you to learn more about your tool. This knowledge builds confidence in your skills.

How to Choose the Right Lathe Repair Kit

Factors to consider when selecting a repair kit. Comparing features and prices among different brands.Choosing a lathe repair kit can feel like picking a favorite candy. There are many options! First, think about what you need. Look for specific features that suit your lathe. Always compare prices too—sometimes, one brand might charge more for the same goodies. Check out this handy table to simplify your search:

| Brand | Features | Price |

|---|---|---|

| Brand A | Watertight, quick fix | $25 |

| Brand B | Includes extras, easy install | $30 |

| Brand C | Long-lasting, lightweight | $20 |

Don’t forget to check reviews! They can save you from experiencing a repair kit that’s more disappointment than delight.

Step-by-Step Guide to Repairing a Metal Lathe Quill

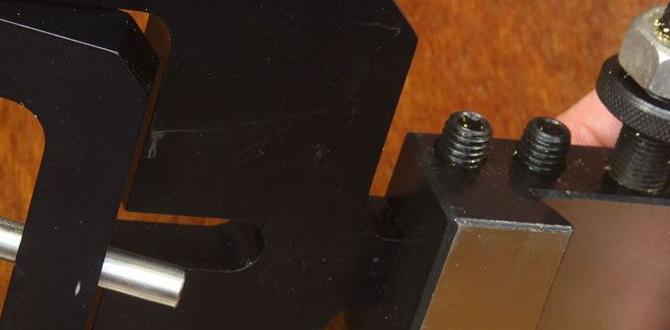

Detailed repair process using a lathe repair kit. Common mistakes to avoid during the repair.Ready to fix that metal lathe quill? Let’s break it down! First, gather your lathe repair kit. Look for tools like wrenches and oil. Begin by carefully disassembling the quill. This step is like solving a puzzle, except if you lose a piece, it’s a big deal! Pay attention to how you take everything apart; it helps in putting it back together.

Now, avoid common mistakes. Don’t rush and forget to clean all parts. Mixed-up parts can lead to more problems—like a puzzle where pieces don’t fit! Also, remember to check if your new parts are compatible. If not, it’s like bringing home the wrong pizza!

| Common Mistake | Solution |

|---|---|

| Skipping cleaning | Always clean before repair! |

| Not checking compatibility | Double-check parts in the kit! |

With step-by-step care, your quill will be spinning smoothly in no time! Happy fixing!

Maintenance Tips for Metal Lathe Quills

Best practices for keeping quills in good condition. Frequency of inspections and maintenance routines.Keeping metal lathe quills in good shape is essential for smooth work. Regular maintenance will help avoid costly repairs. Here are some best practices:

- Check for any signs of wear or damage.

- Clean the quill regularly with a soft cloth.

- Lubricate moving parts to prevent rust.

- Inspect at least once a month, more if used often.

Taking care of your lathe quill will keep it running smoothly and extend its life.

How often should you inspect a metal lathe quill?

Inspect the metal lathe quill at least once a month, or every week for heavy use.Quick Maintenance Tips

- Perform daily checks before starting work.

- Keep a maintenance log for tracking inspections.

Frequently Asked Questions About Lathe Repair Kits

Common queries potential buyers may have. Troubleshooting tips for issues related to quill repairs.Many people have questions about lathe repair kits. Here are some common ones:

What should I look for in a lathe repair kit?

It’s important to find a kit that includes all necessary parts, such as the quill, screws, and tools. Be sure the parts fit your specific lathe model.

How can I troubleshoot quill issues?

If your lathe quill is stuck or not moving smoothly, check for dirt or debris. Here’s what to do:

- Clean the quill area.

- Lubricate moving parts.

- Inspect for wear and tear.

If problems continue, consider replacing parts with a quality lathe repair kit.

Where to Buy the Best Lathe Repair Kits

Recommendations for reputable retailers and online stores. Evaluating the warranty and return policies of sellers.Finding the right place to buy a lathe repair kit is important. Look for stores with good reputations. Check places like local hardware shops or online stores like Amazon and eBay. Make sure they have friendly customer service.

Next, always look at the seller’s warranty and return policy. A good policy shows they care about their customers. For example, a longer warranty means they trust their product quality.

- Amazon – Offers a wide range of options and easy returns.

- eBay – Great for finding unique kits at competitive prices.

- Local Hardware Stores – Provide hands-on help and advice.

Where can I buy the best lathe repair kits?

Look for trusted retailers online and nearby. Check reviews first!

Conclusion

In summary, a lathe repair kit for metal lathe quills is essential for smooth machine operation. It helps you fix common problems easily. We learned that regular maintenance keeps your lathe in shape. If you want to dive deeper, explore online resources for kits or tutorials. This will help you become more skilled in lathe care and repair.FAQs

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Quill?A lathe repair kit for a metal lathe quill usually includes some important parts. You might find bearings, which help the quill turn smoothly. There are also seals to keep dirt out. Sometimes, there are screws and bolts to hold everything together. You may even get a wrench to help with the repairs.

How Do I Determine If A Lathe Quill Needs Repair Or Replacement?To see if your lathe quill needs repair or replacement, check for any damage, like cracks or rust. You should also feel how smoothly it moves. If it sticks or makes strange noises, it may be broken. Finally, if you see parts that are worn out or missing, it’s time to think about replacing it.

What Are The Common Signs Of Wear And Tear In The Quill Of A Metal Lathe?Common signs of wear and tear in the quill of a metal lathe include rough surfaces, rust, and unusual sounds. You might notice it shaking or not moving smoothly anymore. Sometimes it can also have loose parts or gaps. If you see these signs, it’s time to check and fix the quill. Taking care of it helps your lathe work better!

Can I Use A Lathe Repair Kit For Different Brands Or Models Of Metal Lathes?You cannot always use a lathe repair kit for different brands or models. Each lathe is made a little differently. Some parts may not fit right. It’s best to check if the kit matches your lathe first. That way, you know you’re getting the right parts!

What Steps Are Involved In Repairing A Lathe Quill Using A Repair Kit?To repair a lathe quill with a repair kit, first, turn off the lathe and unplug it. Next, remove the quill from the lathe carefully. Then, open the repair kit and find the right parts you need. You can replace broken pieces and put everything back together. Finally, test the quill to make sure it works well before plugging the lathe back in.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Quill? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for a metal lathe quill usually includes some important parts. You might find bearings, which help the quill turn smoothly. There are also seals to keep dirt out. Sometimes, there are screws and bolts to hold everything together. You may even get a wrench to help with the repairs.”}},{“@type”: “Question”,”name”: “How Do I Determine If A Lathe Quill Needs Repair Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if your lathe quill needs repair or replacement, check for any damage, like cracks or rust. You should also feel how smoothly it moves. If it sticks or makes strange noises, it may be broken. Finally, if you see parts that are worn out or missing, it’s time to think about replacing it. “}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear And Tear In The Quill Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of wear and tear in the quill of a metal lathe include rough surfaces, rust, and unusual sounds. You might notice it shaking or not moving smoothly anymore. Sometimes it can also have loose parts or gaps. If you see these signs, it’s time to check and fix the quill. Taking care of it helps your lathe work better!”}},{“@type”: “Question”,”name”: “Can I Use A Lathe Repair Kit For Different Brands Or Models Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You cannot always use a lathe repair kit for different brands or models. Each lathe is made a little differently. Some parts may not fit right. It’s best to check if the kit matches your lathe first. That way, you know you’re getting the right parts!”}},{“@type”: “Question”,”name”: “What Steps Are Involved In Repairing A Lathe Quill Using A Repair Kit? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To repair a lathe quill with a repair kit, first, turn off the lathe and unplug it. Next, remove the quill from the lathe carefully. Then, open the repair kit and find the right parts you need. You can replace broken pieces and put everything back together. Finally, test the quill to make sure it works well before plugging the lathe back in.”}}]}