Have you ever watched a metal lathe work? It’s fascinating! This tool helps shape metal into various forms. However, like any machine, it can sometimes break or wear out. That’s where a lathe repair kit comes in handy. A good kit can save you time and money.

Imagine you are in your workshop, excited about your next project. Suddenly, you notice your lathe saddle isn’t working right. Instead of panicking, you pull out your lathe repair kit. With a few simple steps, you could get back to turning metal again.

Did you know that many people overlook the importance of maintenance? A well-stocked lathe repair kit can make repairs easier and faster. Why wait for a professional when you can fix things yourself? This article will guide you through the essentials of choosing the right repair kit for your metal lathe saddle.

Essential Lathe Repair Kit For Metal Lathe Saddle Maintenance

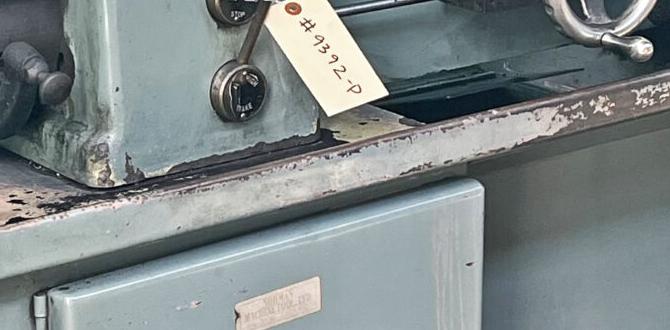

Lathe Repair Kit for Metal Lathe Saddle

A lathe repair kit for the metal lathe saddle is essential for machine maintenance. It helps keep your lathe running smoothly, which can save you time and money. This kit usually includes key parts like bearings, screws, and gaskets. Regularly checking and replacing worn-out components can prevent bigger issues. Did you know that a well-maintained lathe can last for decades? Investing in a repair kit can extend its life and enhance its performance.What is a Lathe Repair Kit?

Definition and purpose of a lathe repair kit. Common components included in metal lathe saddle repair kits.A lathe repair kit helps fix problems with a metal lathe saddle. A lathe is a tool that shapes materials like wood and metal. The kit makes sure the lathe works smoothly again. It usually includes important parts like:

- Bearings

- Gears

- Seals

- Lubricants

- Tools for assembly

Having these parts ready helps keep your lathe in good shape.

What is included in a lathe repair kit?

Commonly, lathe repair kits contain bearings, seals, and gears. These parts work together to keep the lathe running well.

Signs Your Metal Lathe Saddle Needs Repair

Indicators of wear and tear on the saddle. How to diagnose saddle issues effectively.Has your metal lathe saddle been feeling a bit under the weather? Look out for some telltale signs! You might notice strange sounds or feel the saddle wobble like a jelly on a bumpy road. A sticky movement or uneven surface is another red flag. Diagnosing these issues can be as easy as pie—simply inspect for visible cracks or excessive wear. Remember, a well-loved lathe deserves a bit of attention!

| Signs of Trouble | What to Look For |

|---|---|

| Unusual Noises | Clinking or grinding sounds |

| Wobbling | Saddle shakes or moves erratically |

| Sticky Movement | Any resistance during operation |

| Surface Wear | Visible cracks or uneven texture |

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a repair kit for metal lathe saddles. Brand comparisons and quality considerations.Picking the perfect lathe repair kit is like choosing the right toppings for a pizza—one wrong move, and it’s all wrong! First, think about compatibility. Make sure the kit fits your metal lathe saddle like a glove. Next, check the brand. Some brands are like superheroes, while others are more like those sidekicks you forget exist. Quality matters too! A durable kit is worth its weight in gold, or at least pizza dough!

| Brand | Quality | Price |

|---|---|---|

| Brand A | High | $$$ |

| Brand B | Medium | $$ |

| Brand C | Low | $ |

In the end, the right kit can save you time and frustration, letting you get back to turning metal into magic!

Step-by-Step Guide to Using a Lathe Repair Kit

Detailed instructions for repairing a metal lathe saddle. Safety precautions to take during the repair process.Repairing a metal lathe saddle can feel a bit like putting together a giant puzzle. First, gather your lathe repair kit and wear safety goggles, because, let’s face it, no one wants flying metal bits in their eyes. Next, turn off your machine and disconnect it from power. Carefully inspect the saddle for damage. Use the right tools to remove broken parts. Always keep your hands clear of sharp edges. Remember, safety first—unless you want to look like you fought a lawnmower!

| Step | Action |

|---|---|

| 1 | Gather the repair kit |

| 2 | Turn off the machine |

| 3 | Inspect the saddle |

| 4 | Remove broken parts |

| 5 | Install new parts |

Finally, recheck everything before powering on the lathe. Give it a test run to ensure all parts are working smoothly. If it sounds like a rock concert, you might want to check your work again! Happy fixing!

Maintenance Tips for Extending the Life of Your Metal Lathe Saddle

Best practices for routine maintenance. How regular checks can prevent major repairs.To keep your metal lathe saddle in top shape, routine maintenance is key. Regular checks prevent bigger problems later. Here are some best practices:

- Clean and lubricate regularly.

- Inspect for wear and tear.

- Check alignment and adjustments.

- Store tools properly.

This simple care can save you time and money in repairs. Remember, a small effort now means a long-lasting tool later!

How often should you maintain your metal lathe saddle?

You should check your metal lathe saddle at least once a month. Regular maintenance will help you spot issues early and avoid costly repairs. Keeping a routine ensures your lathe works well for years.

FAQs about Lathe Repair Kits and Saddles

Common questions and expert answers regarding lathe repairs. Troubleshooting tips you should know.Many people have questions about lathe repairs. It’s normal to be unsure about how to fix things. Here are some common questions and answers:

What are signs my lathe needs repair?

Look for unusual noises or shaking while it runs. If parts are worn or moving poorly, that’s a sign too.

How do I troubleshoot?

- Check if the power is on.

- Inspect for loose parts.

- Clean the machine regularly.

These steps can help you find problems quickly. A little care goes a long way!

Conclusion

In summary, a lathe repair kit for the metal lathe saddle can help you fix common problems. It usually includes essential tools and parts for easy repairs. By keeping your lathe in good shape, you ensure better results in your projects. Explore more about lathe maintenance to enhance your skills and get the most out of your equipment!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits Specifically For Metal Lathe Saddles:Okay! Here are five questions you might have about lathe repair kits for metal lathe saddles: 1. What is a lathe saddle? A lathe saddle holds the cutting tool. It moves back and forth to shape metal. 2. Why do I need a repair kit? You need a repair kit to fix broken parts. It helps your lathe work like new again. 3. How do I know if my lathe needs repairs? You might hear strange noises or see parts that don’t move. This means it’s time for repairs. 4. Can I fix my lathe myself? Yes, if you have the right repair kit! Just follow the instructions carefully. 5. Where can I buy a lathe repair kit? You can find kits at hardware stores or online. Make sure it fits your lathe!

Sure! Please provide the question you’d like me to answer.

What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Saddle?A lathe repair kit for a metal lathe saddle usually has some important parts. You will find screws, bolts, and washers. These help keep the saddle in place. The kit may also include bearings, which help the saddle move smoothly. Sometimes, there are small tools too, to help you fix things easily.

How Do You Determine If Your Metal Lathe Saddle Needs Repair Or Replacement?To check if your metal lathe saddle needs repair or replacement, look for rust or cracks. You can feel if it moves smoothly. If it sticks or is loose, that’s a bad sign. Check if it fits tightly on the lathe. If it doesn’t fit well, you might need a new one.

What Are Common Signs Of Wear Or Damage In A Metal Lathe Saddle That Might Necessitate A Repair Kit?Common signs of wear or damage in a metal lathe saddle are cracks, dents, or rust. You might also see rough spots where the metal has worn down. If the saddle doesn’t move smoothly, it may need repairs. Look for loose parts that shake or don’t fit well. These problems show it’s time for a repair kit.

How Can Regular Maintenance Help Prevent The Need For A Lathe Repair Kit For The Saddle?Regular maintenance keeps the lathe in good shape. When we clean and oil parts often, they work better. This stops parts from wearing out too quickly. If we look for problems early, we can fix them before they get worse. This helps avoid needing a repair kit.

What Are The Step-By-Step Instructions For Using A Repair Kit To Fix Issues With A Metal Lathe Saddle?First, gather your tools and the repair kit. Make sure you have safety glasses on to protect your eyes. Next, turn off the metal lathe and unplug it. Look for the damaged parts on the saddle. Use the tools from the kit to remove the broken pieces. Replace them with the new parts from the repair kit. Finally, put everything back together and test your metal lathe. Make sure it works smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Repair Kits Specifically For Metal Lathe Saddles:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Okay! Here are five questions you might have about lathe repair kits for metal lathe saddles: 1. What is a lathe saddle? A lathe saddle holds the cutting tool. It moves back and forth to shape metal. 2. Why do I need a repair kit? You need a repair kit to fix broken parts. It helps your lathe work like new again. 3. How do I know if my lathe needs repairs? You might hear strange noises or see parts that don’t move. This means it’s time for repairs. 4. Can I fix my lathe myself? Yes, if you have the right repair kit! Just follow the instructions carefully. 5. Where can I buy a lathe repair kit? You can find kits at hardware stores or online. Make sure it fits your lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Components Are Typically Included In A Lathe Repair Kit For A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe repair kit for a metal lathe saddle usually has some important parts. You will find screws, bolts, and washers. These help keep the saddle in place. The kit may also include bearings, which help the saddle move smoothly. Sometimes, there are small tools too, to help you fix things easily.”}},{“@type”: “Question”,”name”: “How Do You Determine If Your Metal Lathe Saddle Needs Repair Or Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your metal lathe saddle needs repair or replacement, look for rust or cracks. You can feel if it moves smoothly. If it sticks or is loose, that’s a bad sign. Check if it fits tightly on the lathe. If it doesn’t fit well, you might need a new one.”}},{“@type”: “Question”,”name”: “What Are Common Signs Of Wear Or Damage In A Metal Lathe Saddle That Might Necessitate A Repair Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of wear or damage in a metal lathe saddle are cracks, dents, or rust. You might also see rough spots where the metal has worn down. If the saddle doesn’t move smoothly, it may need repairs. Look for loose parts that shake or don’t fit well. These problems show it’s time for a repair kit.”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance Help Prevent The Need For A Lathe Repair Kit For The Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance keeps the lathe in good shape. When we clean and oil parts often, they work better. This stops parts from wearing out too quickly. If we look for problems early, we can fix them before they get worse. This helps avoid needing a repair kit.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Instructions For Using A Repair Kit To Fix Issues With A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, gather your tools and the repair kit. Make sure you have safety glasses on to protect your eyes. Next, turn off the metal lathe and unplug it. Look for the damaged parts on the saddle. Use the tools from the kit to remove the broken pieces. Replace them with the new parts from the repair kit. Finally, put everything back together and test your metal lathe. Make sure it works smoothly!”}}]}