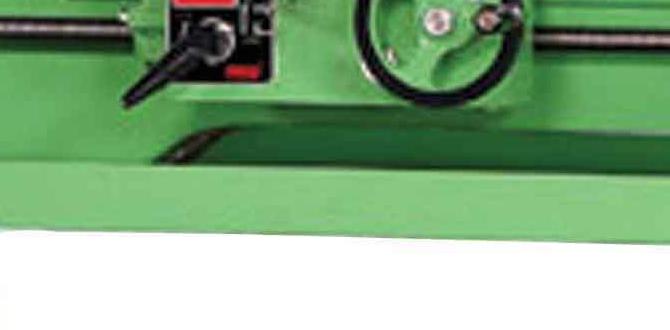

Have you ever watched a metal lathe in action? It’s fascinating how this machine can shape metal into precise parts. But what happens when your lathe stops working properly?

Imagine you’re in the middle of a project and your lathe suddenly breaks down. This can be frustrating! That’s where a lathe repair kit comes in handy. With the right tools, you can fix many common problems. A lathe repair kit can save you time and money.

Setting up a metal lathe might seem complicated, but it can be simple. Knowing how to use a repair kit makes the process easier. You’ll feel proud when you get your lathe running smoothly again.

Did you know that many hobbyists start with metal lathes? They’re fun to use, especially when you see the results of your hard work. Whether you’re a beginner or an expert, understanding lathe maintenance is key. Let’s dive into how a lathe repair kit can help you set up your metal lathe for success!

Essential Lathe Repair Kit For Metal Lathe Setup Success

Understanding Lathe Repair Kits for Your Metal Lathe Setup

Lathe repair kits are essential for anyone working with metal lathes. These kits provide necessary tools and parts to fix common issues that arise in lathes. Imagine struggling with a stuck spindle or worn bearings during a project! With the right lathe repair kit, you can quickly address these problems. This setup not only saves time but also enhances your machine’s performance. Taking care of your lathe ensures your projects go smoothly, giving you better results every time.Understanding Metal Lathes

Definition and purpose of metal lathes. Common applications in various industries.A metal lathe is a tool that shapes metal into precise parts. It spins the metal while cutting tools remove material. This helps make items like screws, pipes, and gears. Metal lathes are essential in many industries, including:

- Automotive: Making engine parts.

- Aerospace: Crafting airplane components.

- Manufacturing: Producing various tools.

- Repair shops: Fixing and creating custom parts.

Using metal lathes improves efficiency and accuracy in production. They are key in transforming raw metal into useful shapes and products.

What is the main use of a metal lathe?

The main use of a metal lathe is to cut, shape, and finish metal items to precise dimensions. This helps in creating various mechanical parts needed in different industries.

Common Issues with Metal Lathes

Identification of typical problems faced. Importance of regular maintenance and inspection.Metal lathes can face some annoying issues that can make your work a bit tricky. You might deal with problems like vibrations, uneven cuts, or even strange noises that sound like a cat caught in a blender! Regular maintenance is super important. Think of it like brushing your teeth; do it often, and you won’t end up with a cavity! Frequent inspections can spot problems early, keeping your lathe running smoothly and saving you from a costly repair later on.

| Common Issues | Importance of Maintenance |

|---|---|

| Vibrations | Prevents major breakdowns |

| Uneven Cuts | Ensures accuracy in projects |

| Strange Noises | Identifies potential problems |

What is a Lathe Repair Kit?

Components included in a lathe repair kit. Benefits of having a repair kit on hand.A lathe repair kit comes with essential tools that help fix and maintain your lathe machine. Common components include wrenches, bearings, and seals. Having a repair kit handy is like having a superhero in your workshop. It helps you avoid long downtimes and costly repairs. Imagine being able to fix a problem before it turns into a drama series!

| Components | Benefits |

|---|---|

| Wrenches | Quick repairs! |

| Bearings | Longer machine life! |

| Seals | Less mess! |

If you want your lathe to run smoothly, a repair kit is your best friend!

Choosing the Right Lathe Repair Kit

Factors to consider when selecting a kit. Comparing different brands and kits available on the market.Picking the right lathe repair kit can feel like choosing a favorite snack—everyone has their own taste! First, think about what you need. Some kits include tools, while others focus on parts. Next, check out different brands. Some are as popular as ice cream on a hot day! Look for kits that fit your lathe model. Read reviews, too! You want a kit that won’t leave you in a lurch. Here’s a quick comparison to help:

| Brand | Features | Price |

|---|---|---|

| Brand A | All-in-one tools | $50 |

| Brand B | Parts only | $30 |

| Brand C | Durable materials | $45 |

Remember, the best choice is the one that meets your needs without emptying your piggy bank!

Step-by-Step Guide to Metal Lathe Setup

Essential tools and materials needed for setup. Detailed instructions on assembling and configuring a metal lathe.Setting up a metal lathe can be simple and fun! First, gather your essential tools: a wrench, a screwdriver, and some oil for lubrication. You’ll also need a sturdy table or stand to place your lathe on. It’s sort of like building a robot; you’ve got to have the right parts!

| Essential Tools | Purpose |

|---|---|

| Wrench | Tightening bolts |

| Screwdriver | Assembling parts |

| Oil | Lubrication |

To assemble, start by securing the lathe to your table. Follow the manual like it’s a treasure map! Next, align all parts carefully. Tighten everything up, making sure nothing wiggles like a dancing jelly. Lastly, add oil to moving parts. Now sit back and admire your work. You just set up a metal lathe!

Maintenance Tips for Longevity

Routine maintenance practices for metal lathes. Signs indicating the need for repair or adjustment.Taking care of your metal lathe is important for it to last longer. Regular maintenance helps keep it running well. Here are some quick tips:

- Check oil levels and add more if low.

- Clean the machine to remove dust and chips.

- Look over belts and gears for wear and tear.

- Ensure all screws and bolts are tight.

Watch for signs like strange noises or difficulty in movement. These can mean it’s time for a repair or adjustment.

What signs show a lathe needs repair?

Strange noises, uneven cuts, and vibrations are key signs your lathe may need repair. Addressing issues early can save money and time later. Keep an eye out for these problems!

DIY Repairs vs. Professional Help

When to consider DIY repairs. Situations that require professional intervention.Doing repairs by yourself can save time and money. DIY repairs are great for small problems you can easily manage. If you know how to use tools, you can fix some settings on your lathe. But, when things are more serious, like broken parts or complex issues, it’s best to call a professional. They have the skills and experience to ensure everything works safely and correctly.

When should you do DIY repairs vs. call a pro?

Consider DIY repairs for:

- Simple adjustments or settings

- Cleaning and basic maintenance

- Replacing small parts

Seek professional help for:

- Major breakdowns

- Complex repairs requiring special tools

- Safety concerns

Frequently Asked Questions about Lathe Repair Kits

Common queries and expert answers regarding repair kits. Tips for troubleshooting issues during setup.Many people wonder about lathe repair kits, and you’re not alone! Common questions pop up, like “What’s included in a repair kit?” or “How do I fix my lathe problems?” Remember, a repair kit usually includes essential parts, like belts and bearings. Always check your manual for help! Troubleshooting can seem tricky, but start with simple fixes. If something is rattling, maybe it just wants to dance! Here’s a quick table for your reference:

| Common Issues | Quick Fixes |

|---|---|

| Lathe not turning | Check the power and switches. |

| Unusual noises | Tighten loose parts. |

| Inaccurate cuts | Realign the tool rest. |

Always consult a pro if you need more help. Happy turning!

Cost Considerations for Lathe Repair Kits

Typical price ranges for quality kits. Longterm savings from investing in a good repair kit.Repair kits for lathes can vary in price. Typically, quality kits range from $100 to $500. While some cheaper kits exist, they may not last long. Investing in a high-quality kit can save money over time. You avoid frequent replacements and repairs. Think of it this way: a good kit is like a sturdy umbrella. It keeps you dry when it rains!

How can a repair kit save you money?

Choosing a good lathe repair kit means fewer repairs. You’ll spend less in the long run. Regular maintenance with a quality kit can lower repair costs by up to 30%! Investing wisely pays off in the end.

Typical Benefits of a Good Kit:

- Longer-lasting tools.

- Lower repair costs.

- Better performance.

Conclusion

In summary, choosing a lathe repair kit is essential for maintaining your metal lathe. Make sure you understand your lathe’s needs. With the right setup, you can improve your projects. We encourage you to explore tutorials and resources online to deepen your knowledge. By taking these steps, you’ll become more skilled and confident in your crafting. Happy machining!FAQs

What Are The Essential Components Included In A Lathe Repair Kit For A Metal Lathe Setup?A lathe repair kit has important tools to fix a metal lathe. You will find wrenches, which help you tighten parts. There are also replacement belts for moving pieces and oil for keeping everything running smoothly. You should have a set of screws and nuts to replace any broken ones. Finally, a cleaning brush helps keep the lathe clean and working well.

How Do I Properly Set Up A Metal Lathe After Performing Repairs With A Lathe Repair Kit?After you fix your metal lathe, start by checking all the parts. Make sure they are tight and in the right place. Next, level the lathe so it stands evenly on the ground. Finally, test it by turning it on and checking that it works smoothly. If everything is okay, you’re ready to use it!

What Common Issues Can Be Resolved Using A Lathe Repair Kit, And When Should A Full Replacement Be Considered?You can use a lathe repair kit to fix common problems like worn bearings, damaged belts, or loose screws. These fix small issues that can make your lathe work better. If the lathe has many big problems or is very old, you might need a full replacement. A new lathe can work more smoothly and last longer than trying to fix everything.

Are There Specific Brands Or Manufacturers Of Lathe Repair Kits That Are Recommended For Different Types Of Metal Lathes?Yes, there are some well-known brands for lathe repair kits. For example, Grizzly and Jet make good kits for metal lathes. You can also try brands like Precision Matthews and South Bend. It’s best to check which kit fits your machine. Always read reviews to find the best one for you!

How Can Regular Maintenance And The Use Of A Lathe Repair Kit Prolong The Lifespan Of A Metal Lathe?We can keep a metal lathe working well by doing regular maintenance. This means cleaning it and checking for problems. Using a lathe repair kit helps fix small issues before they become big ones. When we take good care of our lathe, it lasts longer and works better.